Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Unused- Atlas Copco Model GA200-W Oil Injected 125 PSI, Rotary Screw Compressor. Reference conditions: absolute inlet press 14.5 PSIA, relative humidity 0%, air inlet temperature 69=8F, cooling water...

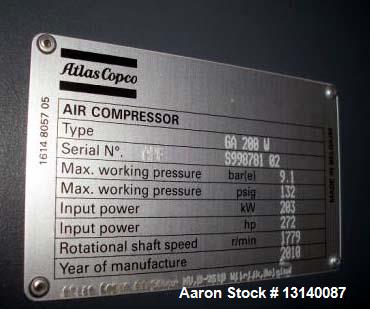

Unused- Atlas Copco Model GA200-W Oil Injected 125 PSI, Rotary Screw Compressor. Reference conditions: absolute inlet press 14.5 PSIA, relative humidity 0%, air inlet temperature 69=8F, cooling water temperature 68F, nominal working pressure 125 PSIG and drive motor shaft speed 1786 RPM. Limitations: maximum working pressure 132 PSIG, minimum working pressure 58 PSIG, maximum allowable air inlet temperature 104F, minimum allowable air inlet temperature 32F. Maximum cooling water temperature of closed system inlet/outlet 104F/140F. Maximum cooling water inlet pressure 145 PSIG. Performance data: flow capacity at working pressures: 132 PSIG/1123 CFM, 125 PSIG/1127 CFM, 100 PSIG/1137 CFM and 58 PSIG/1151 CFM. Power Data: Siemens 250 hp, 3/60/4160 volt TEFC motor, 1800 RPM. Compressor design data: 1 stage, 2 compression elements, male rotor speed 1704 rpm, male rotor diameter 220 mm. Equipped with Elektronikon MKIV control module. Includes Penway wet air receiver. Built 2010.

Unused- Atlas Copco Model GA200-W Oil Injected 125 PSI, Rotary Screw Compressor. Reference conditions: absolute inlet press 14.5 PSIA, relative humidity 0%, air inlet temperature 69=8F, cooling water temperature 68F, nominal working pressure 125 PSIG and drive motor shaft speed 1786 RPM. Limitations: maximum working pressure 132 PSIG, minimum working pressure 58 PSIG, maximum allowable air inlet temperature 104F, minimum allowable air inlet temperature 32F. Maximum cooling water temperature of closed system inlet/outlet 104F/140F. Maximum cooling water inlet pressure 145 PSIG. Performance data: flow capacity at working pressures: 132 PSIG/1123 CFM, 125 PSIG/1127 CFM, 100 PSIG/1137 CFM and 58 PSIG/1151 CFM. Power Data: Siemens 250 hp, 3/60/4160 volt TEFC motor, 1800 RPM. Compressor design data: 1 stage, 2 compression elements, male rotor speed 1704 rpm, male rotor diameter 220 mm. Equipped with Elektronikon MKIV control module. Includes Penway wet air receiver. Built 2010.

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory