Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

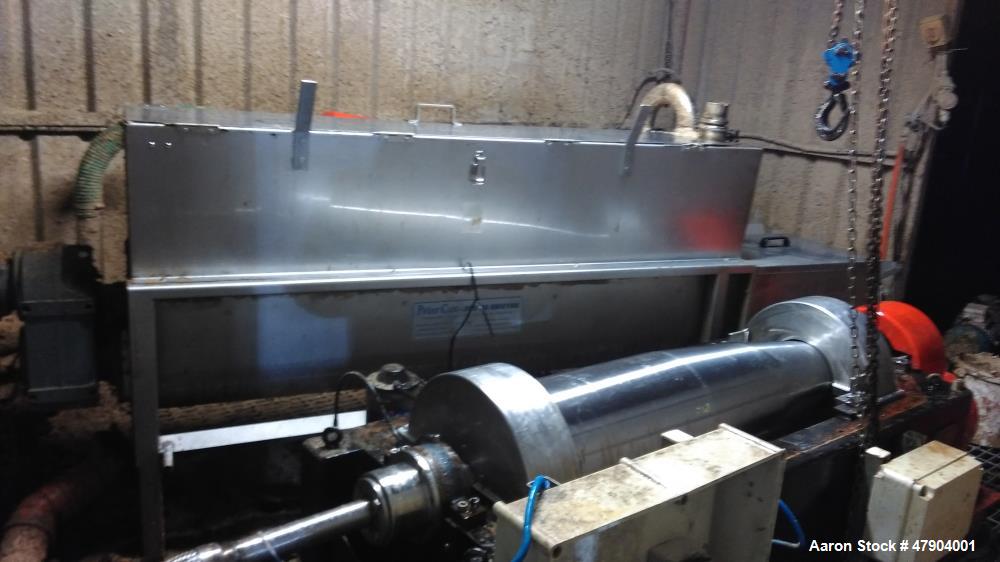

Used Centriquip CQ-3000 Solid Bowl Decanter Centrifuge. Max speed 4500 rpm, 3 x 415 V 50 HZ motor 18.5 Kw control panel. Mfg 2011. Unit is refurbished. Refurbishment includes:. Dismantle the Centrifu...

Used Centriquip CQ-3000 Solid Bowl Decanter Centrifuge. Max speed 4500 rpm, 3 x 415 V 50 HZ motor 18.5 Kw control panel. Mfg 2011. Unit is refurbished. Refurbishment includes:. Dismantle the Centrifuge Completely. Dismantle the R.A. and Hydraulic Rotodiff, clean, inspect and compile service/workshop inspection Report.. Check balance scroll assembley and correct. Check balance bowl assembley and correct. Reassemble the R. A including the Hydraulic Rotodiff. Reassemble the complete R,A back into the base frame.. Reassemble all covers and guards.. Test run the Centrifuge for approximately 6 hrs. Check all instrumentation for correct operation.. Check for leaks.. Check and record bearing temperatures and vibration levels.. Prepare the Centrifuge for dispatch.. Major Service inclusive of all Bearings, Radial Seals, O Rings, Fasteners,. Shot blast Scroll to facilitate repairs. Repair the lead journal on the scroll which is heavily worn. Repair, refurbish and repaint the base frame. inspect and service the centrifuge drive motor and assemble with new bearings/seals and test to confirm correct operation. Replacement of all damaged and cracked ceramic port brushes. Replacement of the Acoustic Cover and Belt Drive Guard

Used Centriquip CQ-3000 Solid Bowl Decanter Centrifuge. Max speed 4500 rpm, 3 x 415 V 50 HZ motor 18.5 Kw control panel. Mfg 2011. Unit is refurbished. Refurbishment includes:. Dismantle the Centrifuge Completely. Dismantle the R.A. and Hydraulic Rotodiff, clean, inspect and compile service/workshop inspection Report.. Check balance scroll assembley and correct. Check balance bowl assembley and correct. Reassemble the R. A including the Hydraulic Rotodiff. Reassemble the complete R,A back into the base frame.. Reassemble all covers and guards.. Test run the Centrifuge for approximately 6 hrs. Check all instrumentation for correct operation.. Check for leaks.. Check and record bearing temperatures and vibration levels.. Prepare the Centrifuge for dispatch.. Major Service inclusive of all Bearings, Radial Seals, O Rings, Fasteners,. Shot blast Scroll to facilitate repairs. Repair the lead journal on the scroll which is heavily worn. Repair, refurbish and repaint the base frame. inspect and service the centrifuge drive motor and assemble with new bearings/seals and test to confirm correct operation. Replacement of all damaged and cracked ceramic port brushes. Replacement of the Acoustic Cover and Belt Drive Guard

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory