Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Used Cleaver Brooks Heat Recovery Steam Generator (HRSG) – 90,000 lb/hr Capacity

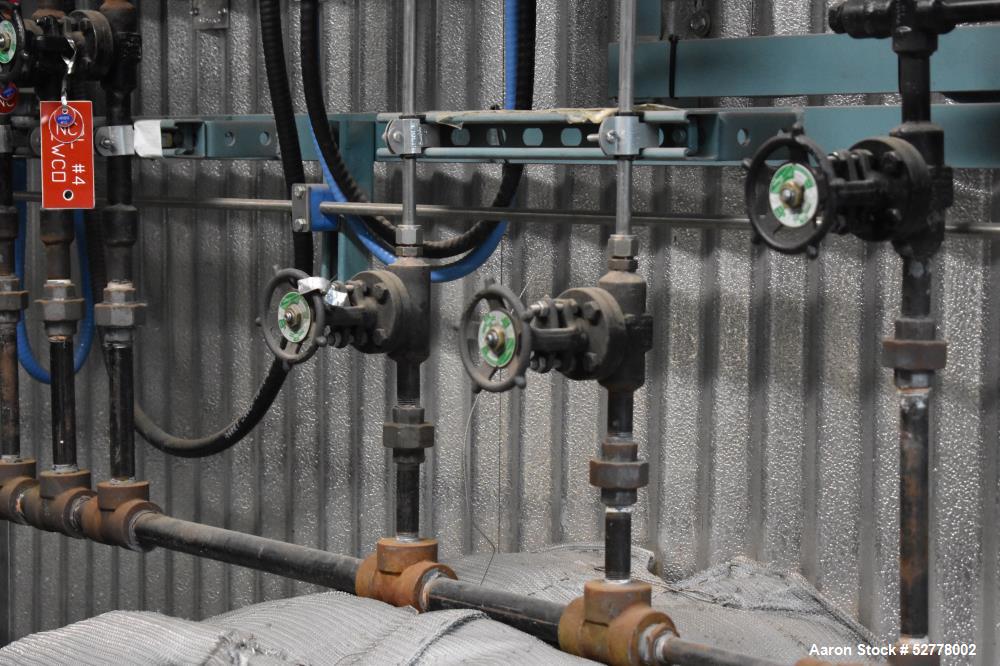

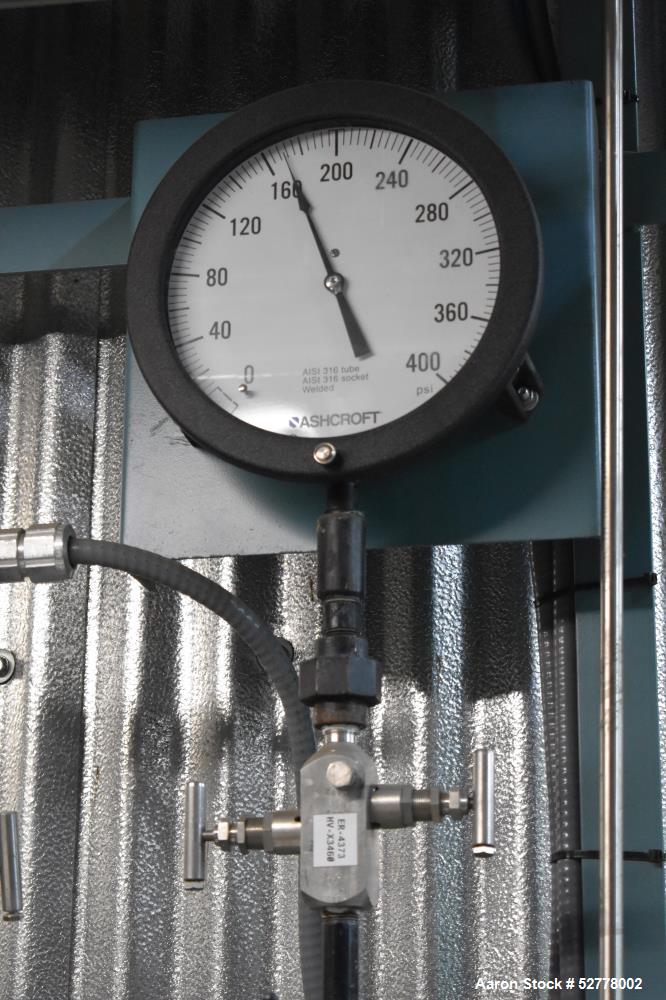

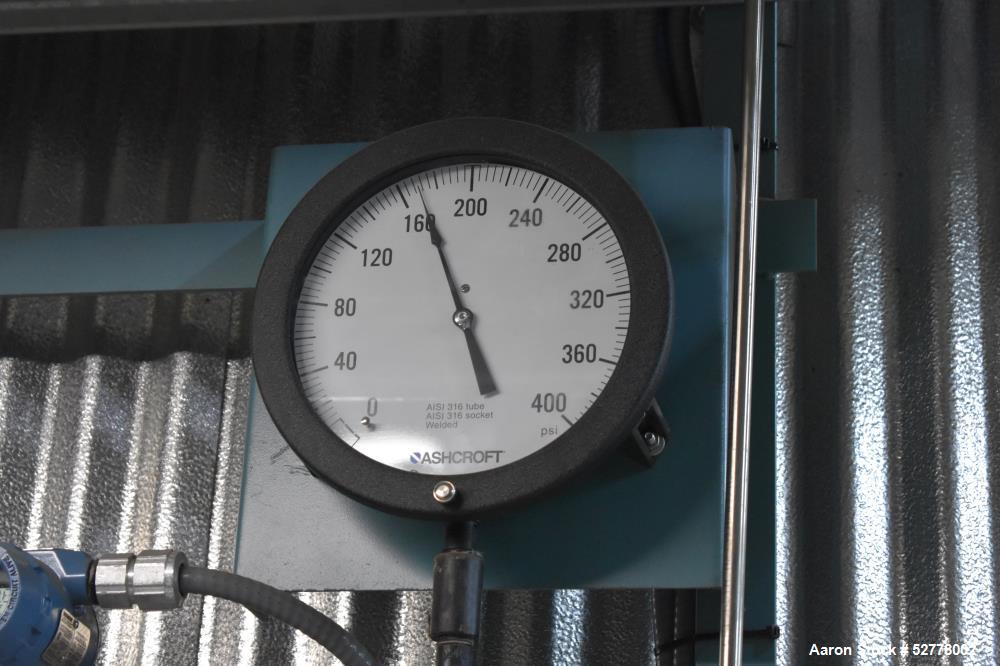

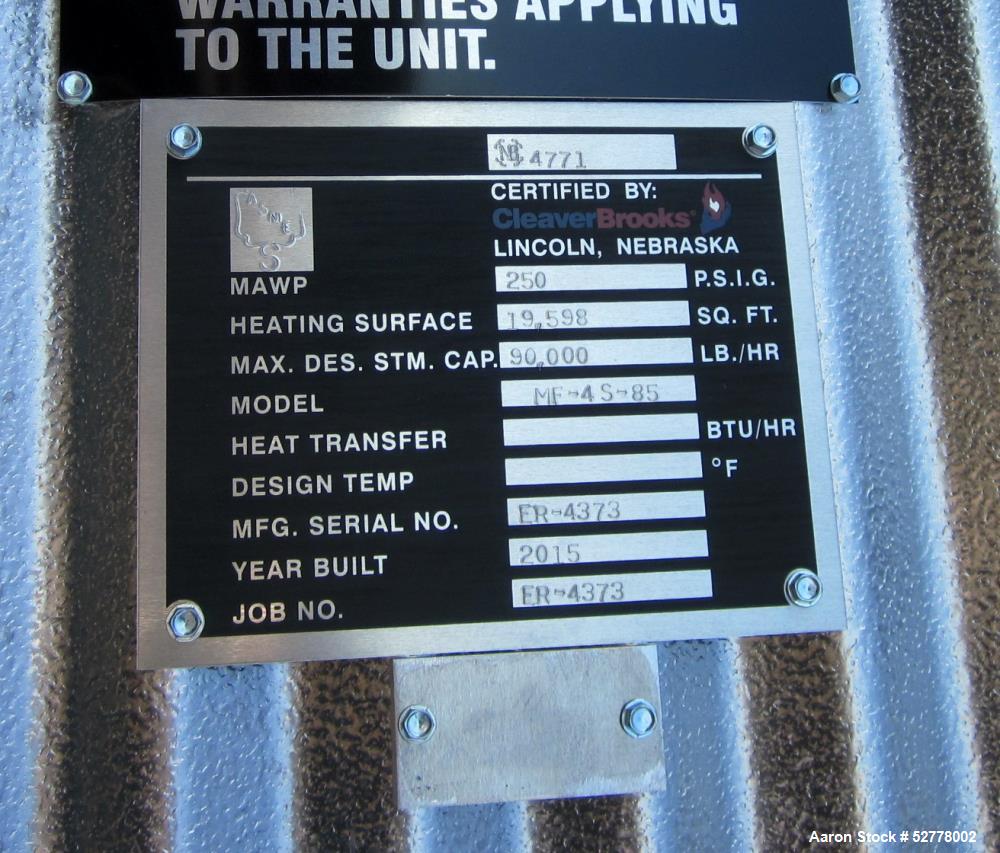

Used Cleaver Brooks Heat Recovery Steam Generator (HRSG); Model MF-4/S-85; Burner Model DB-66-G-3; Capacity 90,000 lb/hr (170 psig saturated steam); O-type HRSG with mud dream and steam drum; Natcom Duct Burner System; (3) Duct Burner Elements; Burner Management System; Top exhaust to feedwater economizer. Mfg. 2015. Our freight specialists can assist you with door to door transportation and all customs documents needed to make the process go as smoothly as possible. Year built: 2015

Manufacturer Information:

- Manufacturer: Cleaver Brooks

- Model: MF-4/S-85

- Condition: Used

- Year Built: 2015

Manufacturing Data:

- Capacity: 90,000 lb/hr (170 psig saturated steam)

- HRSG Type: O-type with mud drum and steam drum

- Burner Model: DB-66-G-3

- Duct Burner System: Natcom

- Duct Burner Elements: (3)

- Burner Management System: Yes

- Exhaust System: Top exhaust to feedwater economizer

Description:

The Cleaver Brooks MF-4/S-85 Heat Recovery Steam Generator (HRSG) is a high-efficiency industrial boiler system designed to recover waste heat and convert it into steam. With a 90,000 lb/hr steam production capacity at 170 psig, this HRSG is ideal for large-scale power plants, refineries, and industrial steam applications.

Featuring an O-type design with both a mud drum and steam drum, this HRSG ensures efficient heat transfer and reliable operation. The system is equipped with a Natcom Duct Burner System, including three duct burner elements, allowing for additional steam generation when needed.

The integrated burner management system (BMS) provides automated monitoring and safety controls, while the top exhaust design feeds directly into the economizer, maximizing heat recovery efficiency.

Specifications:

- Steam Capacity: 90,000 lb/hr

- Pressure Rating: 170 psig saturated steam

- Burner Model: DB-66-G-3

- HRSG Configuration: O-type with mud drum and steam drum

- Duct Burner System: Natcom with (3) duct burner elements

- Exhaust System: Top exhaust to feedwater economizer

- Burner Management System: Integrated for control and monitoring

- Year Built: 2015

Applications:

- Power generation

- Refinery and petrochemical plant operations

- Industrial steam generation

- Waste heat recovery for large-scale industrial processes

- Cogeneration (combined heat and power) systems

Potential Uses:

- Steam production for power plants

- Boiler feedwater heating through waste heat recovery

- High-efficiency industrial heat and steam management

- Supplementary firing for increased steam output in industrial processes

- Process steam for manufacturing, food production, and chemical processing

- Used HRSG

- Cleaver Brooks boiler

- Industrial steam generator

- Heat recovery boiler

- Waste heat boiler

- O-type boiler

- HRSG system

- High-capacity steam boiler

- Duct burner system

- Steam production unit

- Industrial heat recovery

- Power plant boiler

- Cogeneration boiler

- Steam drum boiler

- Heat recovery system

- Used Cleaver Brooks HRSG

- Industrial heat recovery steam generator

- 90,000 lb/hr steam boiler

- Waste heat recovery system

- O-type HRSG boiler

- Used Cleaver Brooks MF-4/S-85 HRSG for industrial steam generation

- Heat recovery steam generator with 90,000 lb/hr capacity

- Industrial O-type HRSG with duct burner system

- High-efficiency heat recovery steam generator for power plants

- Used HRSG boiler with Natcom duct burner and burner management system

- Used Cleaver Brooks 90,000 lb/hr heat recovery steam generator with burner management system

- Industrial-grade HRSG with mud drum, steam drum, and top exhaust feedwater economizer

- O-type HRSG for power generation and refinery applications with duct burner system

- High-capacity heat recovery steam generator with integrated Natcom duct burner elements

- Cleaver Brooks HRSG boiler with supplementary firing for enhanced steam production

Used Cleaver Brooks Heat Recovery Steam Generator (HRSG); Model MF-4/S-85; Burner Model DB-66-G-3; Capacity 90,000 lb/hr (170 psig saturated steam); O-type HRSG with mud dream and steam drum; Natcom Duct Burner System; (3) Duct Burner Elements; Burner Management System; Top exhaust to feedwater economizer. Mfg. 2015. Our freight specialists can assist you with door to door transportation and all customs documents needed to make the process go as smoothly as possible. Year built: 2015

Manufacturer Information:

- Manufacturer: Cleaver Brooks

- Model: MF-4/S-85

- Condition: Used

- Year Built: 2015

Manufacturing Data:

- Capacity: 90,000 lb/hr (170 psig saturated steam)

- HRSG Type: O-type with mud drum and steam drum

- Burner Model: DB-66-G-3

- Duct Burner System: Natcom

- Duct Burner Elements: (3)

- Burner Management System: Yes

- Exhaust System: Top exhaust to feedwater economizer

Description:

The Cleaver Brooks MF-4/S-85 Heat Recovery Steam Generator (HRSG) is a high-efficiency industrial boiler system designed to recover waste heat and convert it into steam. With a 90,000 lb/hr steam production capacity at 170 psig, this HRSG is ideal for large-scale power plants, refineries, and industrial steam applications.

Featuring an O-type design with both a mud drum and steam drum, this HRSG ensures efficient heat transfer and reliable operation. The system is equipped with a Natcom Duct Burner System, including three duct burner elements, allowing for additional steam generation when needed.

The integrated burner management system (BMS) provides automated monitoring and safety controls, while the top exhaust design feeds directly into the economizer, maximizing heat recovery efficiency.

Specifications:

- Steam Capacity: 90,000 lb/hr

- Pressure Rating: 170 psig saturated steam

- Burner Model: DB-66-G-3

- HRSG Configuration: O-type with mud drum and steam drum

- Duct Burner System: Natcom with (3) duct burner elements

- Exhaust System: Top exhaust to feedwater economizer

- Burner Management System: Integrated for control and monitoring

- Year Built: 2015

Applications:

- Power generation

- Refinery and petrochemical plant operations

- Industrial steam generation

- Waste heat recovery for large-scale industrial processes

- Cogeneration (combined heat and power) systems

Potential Uses:

- Steam production for power plants

- Boiler feedwater heating through waste heat recovery

- High-efficiency industrial heat and steam management

- Supplementary firing for increased steam output in industrial processes

- Process steam for manufacturing, food production, and chemical processing

- Used HRSG

- Cleaver Brooks boiler

- Industrial steam generator

- Heat recovery boiler

- Waste heat boiler

- O-type boiler

- HRSG system

- High-capacity steam boiler

- Duct burner system

- Steam production unit

- Industrial heat recovery

- Power plant boiler

- Cogeneration boiler

- Steam drum boiler

- Heat recovery system

- Used Cleaver Brooks HRSG

- Industrial heat recovery steam generator

- 90,000 lb/hr steam boiler

- Waste heat recovery system

- O-type HRSG boiler

- Used Cleaver Brooks MF-4/S-85 HRSG for industrial steam generation

- Heat recovery steam generator with 90,000 lb/hr capacity

- Industrial O-type HRSG with duct burner system

- High-efficiency heat recovery steam generator for power plants

- Used HRSG boiler with Natcom duct burner and burner management system

- Used Cleaver Brooks 90,000 lb/hr heat recovery steam generator with burner management system

- Industrial-grade HRSG with mud drum, steam drum, and top exhaust feedwater economizer

- O-type HRSG for power generation and refinery applications with duct burner system

- High-capacity heat recovery steam generator with integrated Natcom duct burner elements

- Cleaver Brooks HRSG boiler with supplementary firing for enhanced steam production

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory