Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

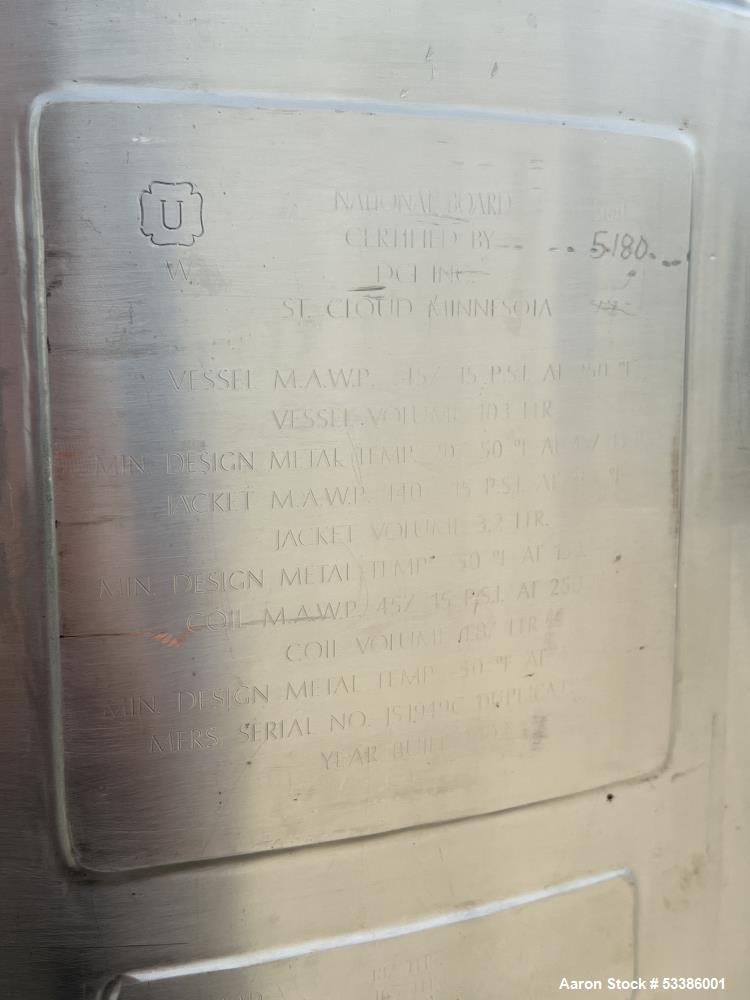

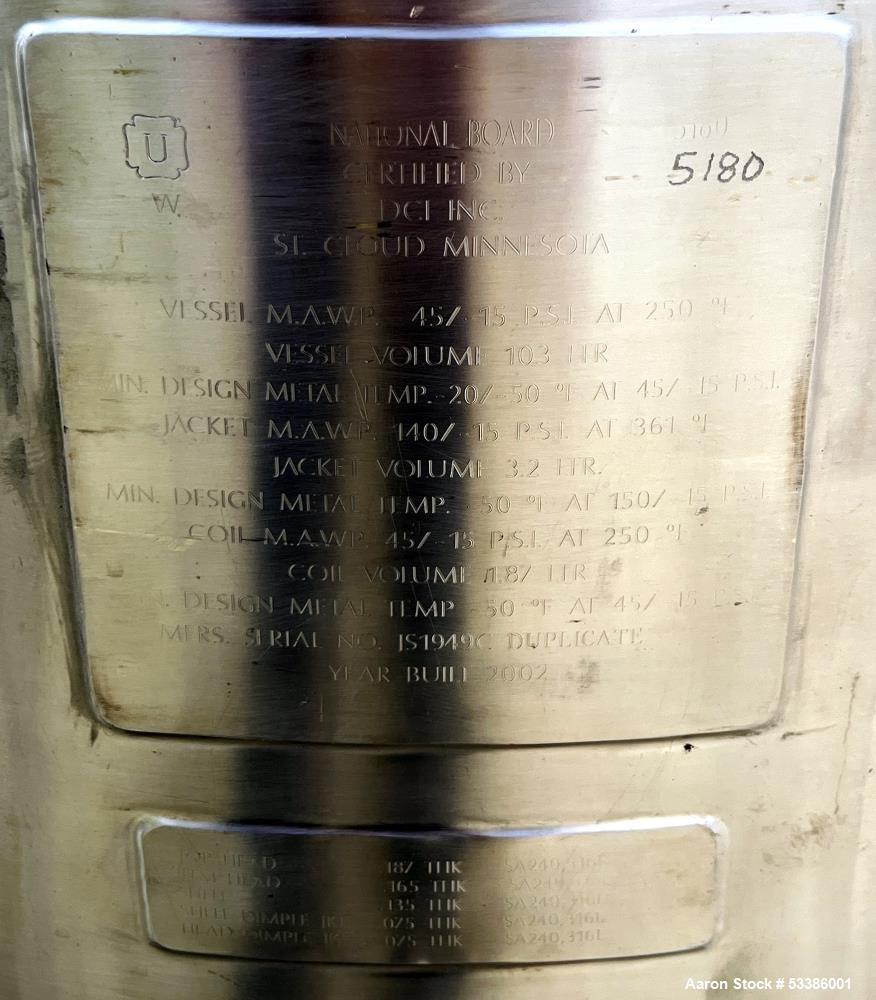

Used DCI 103 Liter / 27.2 Gallon Jacketed Tank

$3,800.00

Used DCI 103 Liter / 27.2 Gallon Jacketed Tank, 316L Stainless Steel, Vertical. Approximate 20" diameter x 26" straight side. Dished removable top head, dished bottom head. 316L Stainless steel dimple jacket, rated 140psi / FV at -20 to 361 degrees F. Internal rated 45psi / FV at -20 to 250 degrees F. Openings: (5) 3", (1) 1-1/2". (2) 1", 1-1/2" Center bottom outlet with approximately 8-10" discharge height.. (4) internal baffles. Shell & Bottom head 3" inswool insulation and sheathed. Mounted on (4) legs with casters. Serial# JS1949C, National Board# 5180. Used as Freeze / Thaw Vessel. Repaired in 2009 by DCI.

| Serial # | JS1949C |

| Category | TanksTanks |

| Subcategory | Stainless 0-499 GalStainless 0-499 Gal |

| Gallons | 27.2 |

| Material of Construction | 316L Stainless Steel |

| Horizontal or Vertical | Vertical |

| Diameter | 20" |

| Straight Side | 26" |

| Top Head Style | Dished Head |

| Bottom | Dished Bottom |

| Internal Pressure | 45 / FV |

| Internal Temperature | -50 to 250 F |

| Opening | (5) 3", 1-1/2", (2) 1" |

| Opening Cover | Yes |

| Outlet Size | 1-1/2" |

| Outlet Location | Bottom |

| Discharge Height | 8-10" |

| Mounted | Mounted on Casters |

| National Board No. | 5180 |

| Overall Dimensions | 38" x 38" x 50"T |

| Year Built | 2002 |

Manufacturer Information:

- Manufacturer: DCI

- Capacity: 103 Liters (27.2 Gallons)

- Material: 316L Stainless Steel (Product Contact and Jacket)

- Condition: Used (Repaired by DCI in 2009)

- Serial Number: JS1949C

- National Board Number: 5180

Description:

This DCI 103-liter (27.2-gallon) jacketed tank is specifically designed for temperature-sensitive processing, including freeze/thaw applications in pharmaceutical, biotech, food, and chemical industries. The 316L stainless steel construction for both product contact surfaces and jacket ensures high corrosion resistance, durability, and sanitary compliance for regulated processing environments.

The 316L stainless steel dimple jacket is rated for 140 PSI / full vacuum (FV) at -20°F to 361°F, providing efficient thermal regulation for heating and cooling processes. The internal chamber is rated at 45 PSI / FV at -20°F to 250°F, making it suitable for vacuum and pressure-controlled applications.

The tank features a dished removable top head and a dished bottom head, (4) internal baffles for enhanced mixing efficiency, and 3” inswool insulation with sheathing on the shell and bottom head for improved thermal efficiency.

This unit includes multiple process openings for integration with various processing systems:

- (5) 3” openings

- (1) 1-1/2” opening

- (2) 1” openings

- 1-1/2” center bottom outlet with approximately 8-10” discharge height

Mounted on (4) stainless steel legs with casters, the tank is highly mobile and easy to position within production environments.

Specifications:

- Capacity: 103 Liters (27.2 Gallons)

- Material: 316L Stainless Steel (Product Contact and Jacket)

- Orientation: Vertical

- Dimensions:

- Diameter: 20"

- Straight-Side Height: 26"

- Top Configuration: Dished, Removable

- Bottom Configuration: Dished

- Pressure Ratings:

- Internal: 45 PSI / Full Vacuum (FV) at -20°F to 250°F

- Jacket: 140 PSI / Full Vacuum (FV) at -20°F to 361°F

- Insulation: 3" Inswool Insulation & Sheathed (Shell & Bottom Head)

- Openings:

- (5) 3” Openings

- (1) 1-1/2” Opening

- (2) 1” Openings

- 1-1/2” Center Bottom Outlet with 8-10” Discharge Height

- Mixing Features: (4) Internal Baffles for Improved Mixing Efficiency

- Mobility: Mounted on (4) Stainless Steel Legs with Casters

- Condition: Used (Repaired by DCI in 2009, Designed as Freeze/Thaw Vessel)

Applications:

This stainless steel jacketed tank is ideal for precision-controlled temperature processing, including:

- Pharmaceutical & Biotech Manufacturing – Freeze/thaw applications, buffer preparation, and liquid formulation

- Food & Beverage Industry – Ingredient storage, mixing, and temperature-controlled processing

- Chemical Processing – Small-scale specialty chemical reactions and formulation testing

- Cosmetic & Personal Care – Blending and emulsification of creams, lotions, and skincare products

- Petrochemical & Lubricants – Controlled storage of specialty oils, waxes, and lubricants

- Adhesives, Coatings & Paints – Formulation of adhesives, resins, and coatings

- Plastics & Polymer Processing – Small-batch polymerization and blending

- Laboratory & Research Applications – Precision reaction environment for material sciences

What Products Would This Be Used For?

This jacketed vessel is suitable for processing:

- Pharmaceutical buffer solutions and liquid formulations

- Freeze/thaw-sensitive biopharmaceutical products

- Food-grade liquid ingredients and emulsions

- Cosmetic lotions, creams, and active ingredient blends

- Chemical solutions requiring precise temperature control

- Adhesives, resins, and high-performance coatings

- Specialty oils, waxes, and lubricants

- Research & development applications for controlled experiments

- Used 103-Liter Stainless Steel Jacketed Tank for Sale

- DCI 27.2-Gallon Freeze/Thaw Vessel with Insulation

- 316L Stainless Steel Vertical Tank with High-Pressure Jacket

- High-Performance Jacketed Processing Tank for Pharmaceuticals

- Used 27.2-Gallon Stainless Steel Mixing & Storage Tank

- Industrial Freeze/Thaw Vessel with Internal Baffles & Insulation

- DCI Stainless Steel Vessel with Casters for Mobility

- 140 PSI Jacketed Tank for Controlled Heating & Cooling

- Used 103-liter stainless steel jacketed tank for pharmaceutical applications

- Best stainless steel freeze/thaw vessel for temperature-controlled processing

- DCI 27.2-gallon tank with dished top and bottom for industrial applications

- Used 316L stainless steel process tank with insulated jacket

- High-performance freeze/thaw vessel for biotech and chemical processing

- Stainless steel storage tank with internal baffles for mixing applications

- Best used jacketed processing tank with mobility for industrial applications

- Used high-purity stainless steel vessel for temperature-sensitive manufacturing

- Where to buy a used 103-liter stainless steel jacketed tank with full vacuum rating

- Best small-scale freeze/thaw vessel for pharmaceutical and biotech applications

- Used stainless steel jacketed processing tank for food and cosmetic formulations

- High-purity 316L stainless steel storage vessel with internal baffles

- Best used industrial mixing tank for temperature-sensitive liquids

- Small-scale dimple jacketed stainless steel tank for laboratory and R&D processing

- Used DCI freeze/thaw vessel with insulation and casters for mobility

- Affordable high-performance 27.2-gallon stainless steel processing tank

Used DCI 103 Liter / 27.2 Gallon Jacketed Tank, 316L Stainless Steel, Vertical. Approximate 20" diameter x 26" straight side. Dished removable top head, dished bottom head. 316L Stainless steel dimple jacket, rated 140psi / FV at -20 to 361 degrees F. Internal rated 45psi / FV at -20 to 250 degrees F. Openings: (5) 3", (1) 1-1/2". (2) 1", 1-1/2" Center bottom outlet with approximately 8-10" discharge height.. (4) internal baffles. Shell & Bottom head 3" inswool insulation and sheathed. Mounted on (4) legs with casters. Serial# JS1949C, National Board# 5180. Used as Freeze / Thaw Vessel. Repaired in 2009 by DCI.

Manufacturer Information:

- Manufacturer: DCI

- Capacity: 103 Liters (27.2 Gallons)

- Material: 316L Stainless Steel (Product Contact and Jacket)

- Condition: Used (Repaired by DCI in 2009)

- Serial Number: JS1949C

- National Board Number: 5180

Description:

This DCI 103-liter (27.2-gallon) jacketed tank is specifically designed for temperature-sensitive processing, including freeze/thaw applications in pharmaceutical, biotech, food, and chemical industries. The 316L stainless steel construction for both product contact surfaces and jacket ensures high corrosion resistance, durability, and sanitary compliance for regulated processing environments.

The 316L stainless steel dimple jacket is rated for 140 PSI / full vacuum (FV) at -20°F to 361°F, providing efficient thermal regulation for heating and cooling processes. The internal chamber is rated at 45 PSI / FV at -20°F to 250°F, making it suitable for vacuum and pressure-controlled applications.

The tank features a dished removable top head and a dished bottom head, (4) internal baffles for enhanced mixing efficiency, and 3” inswool insulation with sheathing on the shell and bottom head for improved thermal efficiency.

This unit includes multiple process openings for integration with various processing systems:

- (5) 3” openings

- (1) 1-1/2” opening

- (2) 1” openings

- 1-1/2” center bottom outlet with approximately 8-10” discharge height

Mounted on (4) stainless steel legs with casters, the tank is highly mobile and easy to position within production environments.

Specifications:

- Capacity: 103 Liters (27.2 Gallons)

- Material: 316L Stainless Steel (Product Contact and Jacket)

- Orientation: Vertical

- Dimensions:

- Diameter: 20"

- Straight-Side Height: 26"

- Top Configuration: Dished, Removable

- Bottom Configuration: Dished

- Pressure Ratings:

- Internal: 45 PSI / Full Vacuum (FV) at -20°F to 250°F

- Jacket: 140 PSI / Full Vacuum (FV) at -20°F to 361°F

- Insulation: 3" Inswool Insulation & Sheathed (Shell & Bottom Head)

- Openings:

- (5) 3” Openings

- (1) 1-1/2” Opening

- (2) 1” Openings

- 1-1/2” Center Bottom Outlet with 8-10” Discharge Height

- Mixing Features: (4) Internal Baffles for Improved Mixing Efficiency

- Mobility: Mounted on (4) Stainless Steel Legs with Casters

- Condition: Used (Repaired by DCI in 2009, Designed as Freeze/Thaw Vessel)

Applications:

This stainless steel jacketed tank is ideal for precision-controlled temperature processing, including:

- Pharmaceutical & Biotech Manufacturing – Freeze/thaw applications, buffer preparation, and liquid formulation

- Food & Beverage Industry – Ingredient storage, mixing, and temperature-controlled processing

- Chemical Processing – Small-scale specialty chemical reactions and formulation testing

- Cosmetic & Personal Care – Blending and emulsification of creams, lotions, and skincare products

- Petrochemical & Lubricants – Controlled storage of specialty oils, waxes, and lubricants

- Adhesives, Coatings & Paints – Formulation of adhesives, resins, and coatings

- Plastics & Polymer Processing – Small-batch polymerization and blending

- Laboratory & Research Applications – Precision reaction environment for material sciences

What Products Would This Be Used For?

This jacketed vessel is suitable for processing:

- Pharmaceutical buffer solutions and liquid formulations

- Freeze/thaw-sensitive biopharmaceutical products

- Food-grade liquid ingredients and emulsions

- Cosmetic lotions, creams, and active ingredient blends

- Chemical solutions requiring precise temperature control

- Adhesives, resins, and high-performance coatings

- Specialty oils, waxes, and lubricants

- Research & development applications for controlled experiments

| Serial # | JS1949C |

| Category | Tanks |

| Subcategory | Stainless 0-499 Gal |

| Gallons | 27.2 |

| Material of Construction | 316L Stainless Steel |

| Horizontal or Vertical | Vertical |

| Diameter | 20" |

| Straight Side | 26" |

| Top Head Style | Dished Head |

| Bottom | Dished Bottom |

| Internal Pressure | 45 / FV |

| Internal Temperature | -50 to 250 F |

| Opening | (5) 3", 1-1/2", (2) 1" |

| Opening Cover | Yes |

| Outlet Size | 1-1/2" |

| Outlet Location | Bottom |

| Discharge Height | 8-10" |

| Mounted | Mounted on Casters |

| National Board No. | 5180 |

| Overall Dimensions | 38" x 38" x 50"T |

| Year Built | 2002 |

- Used 103-Liter Stainless Steel Jacketed Tank for Sale

- DCI 27.2-Gallon Freeze/Thaw Vessel with Insulation

- 316L Stainless Steel Vertical Tank with High-Pressure Jacket

- High-Performance Jacketed Processing Tank for Pharmaceuticals

- Used 27.2-Gallon Stainless Steel Mixing & Storage Tank

- Industrial Freeze/Thaw Vessel with Internal Baffles & Insulation

- DCI Stainless Steel Vessel with Casters for Mobility

- 140 PSI Jacketed Tank for Controlled Heating & Cooling

- Used 103-liter stainless steel jacketed tank for pharmaceutical applications

- Best stainless steel freeze/thaw vessel for temperature-controlled processing

- DCI 27.2-gallon tank with dished top and bottom for industrial applications

- Used 316L stainless steel process tank with insulated jacket

- High-performance freeze/thaw vessel for biotech and chemical processing

- Stainless steel storage tank with internal baffles for mixing applications

- Best used jacketed processing tank with mobility for industrial applications

- Used high-purity stainless steel vessel for temperature-sensitive manufacturing

- Where to buy a used 103-liter stainless steel jacketed tank with full vacuum rating

- Best small-scale freeze/thaw vessel for pharmaceutical and biotech applications

- Used stainless steel jacketed processing tank for food and cosmetic formulations

- High-purity 316L stainless steel storage vessel with internal baffles

- Best used industrial mixing tank for temperature-sensitive liquids

- Small-scale dimple jacketed stainless steel tank for laboratory and R&D processing

- Used DCI freeze/thaw vessel with insulation and casters for mobility

- Affordable high-performance 27.2-gallon stainless steel processing tank

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory