Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

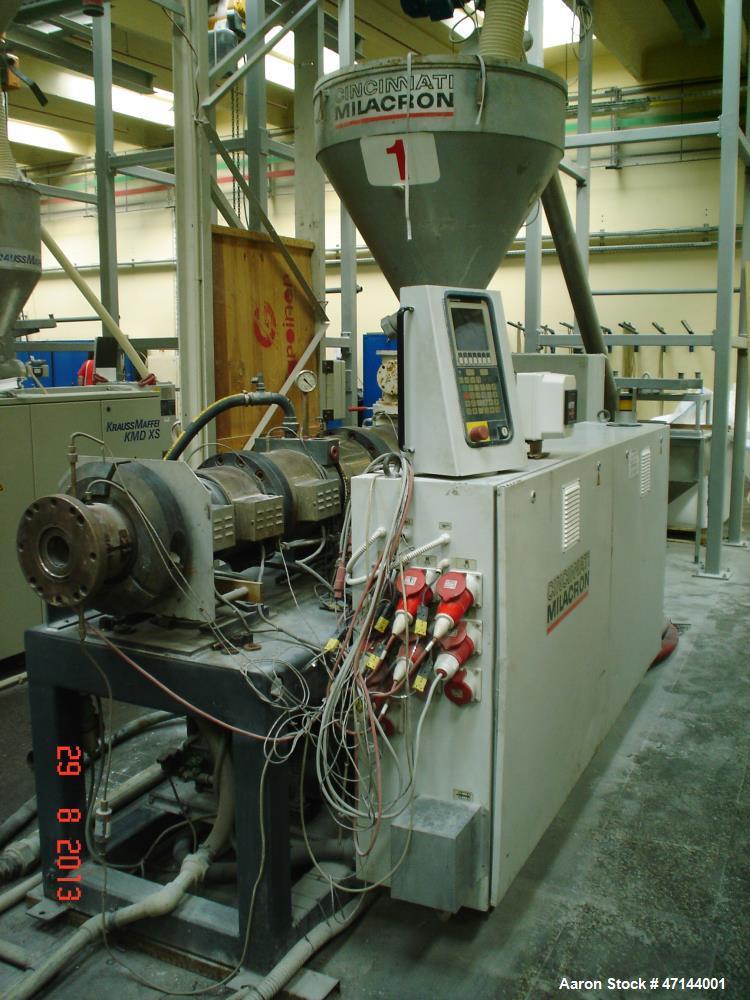

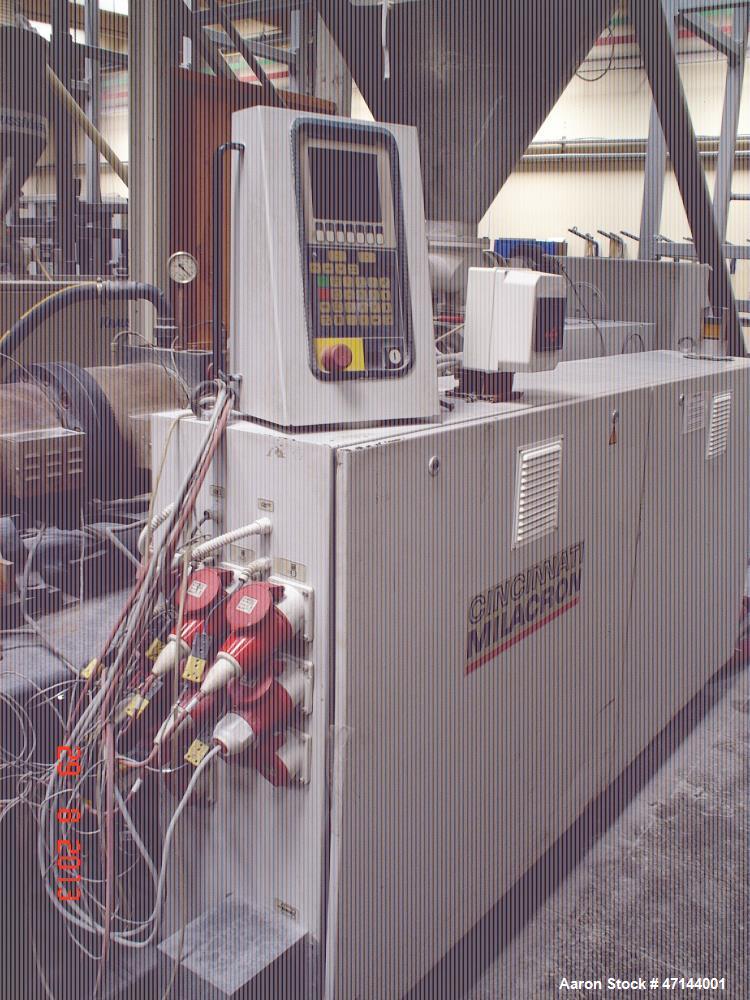

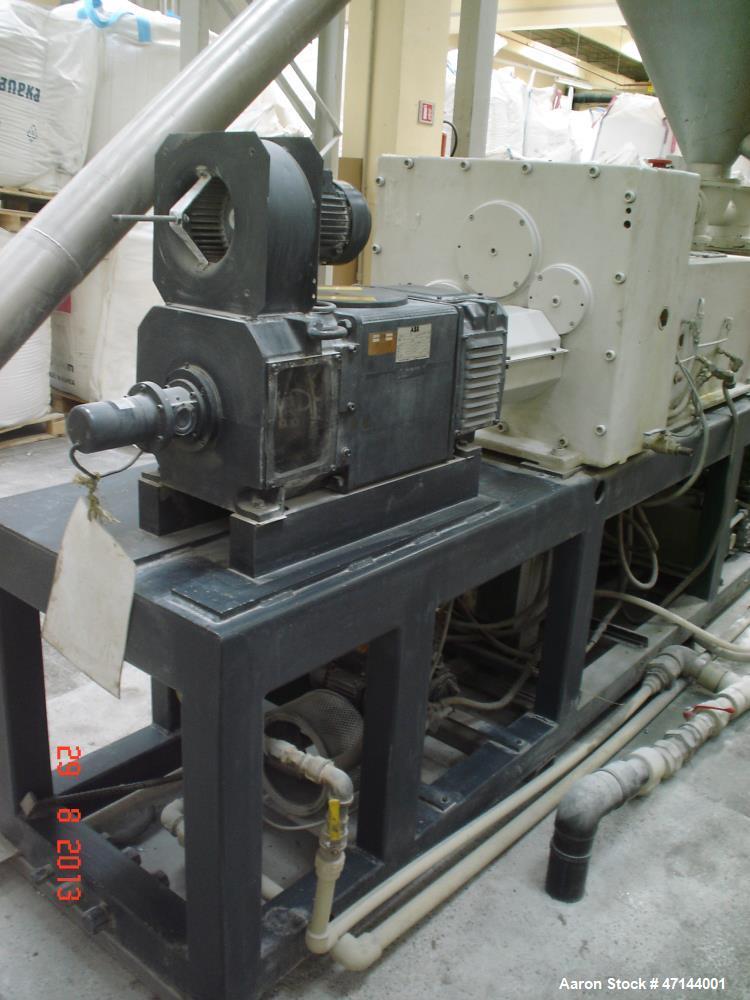

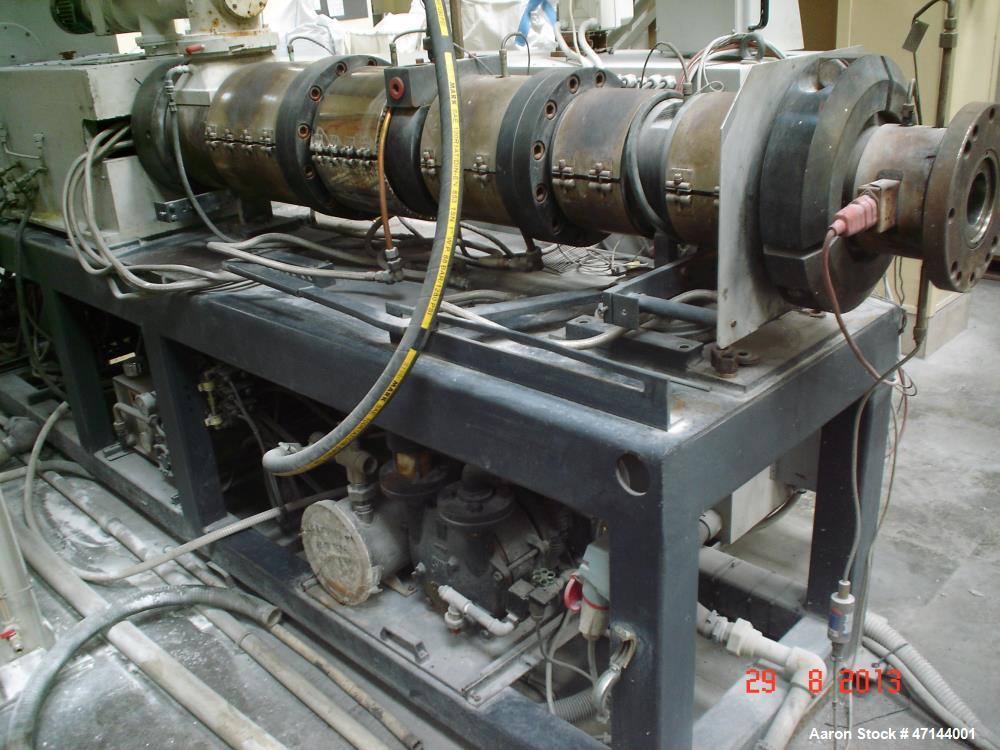

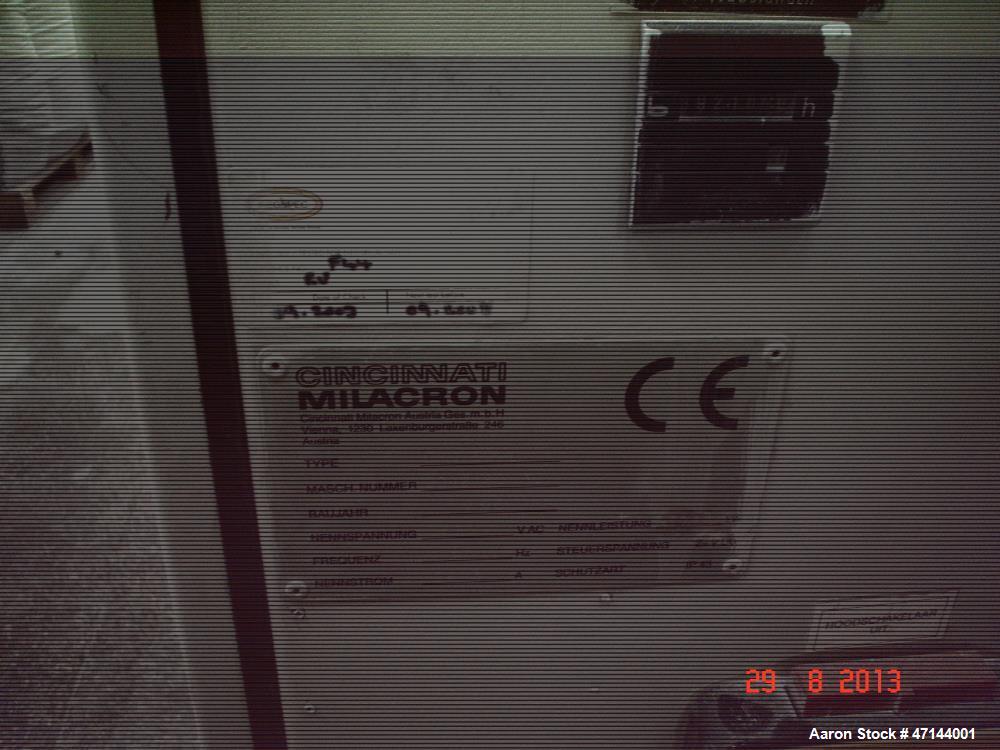

Used Cincinnati Twin-Screw Extruder Conical Milacron CMT 80-L. Year of production: 1995. Work hours: 39218 h D.C. shunt motor: 46kW Rating, installed and set: 1480.0 min-1 Speed: 297 Nm Torque: 0.7 k...

Used Cincinnati Twin-Screw Extruder Conical Milacron CMT 80-L. Year of production: 1995. Work hours: 39218 h D.C. shunt motor: 46kW Rating, installed and set: 1480.0 min-1 Speed: 297 Nm Torque: 0.7 kW External fan: Power Transmission: 59.19 (1) Distribution Gear Bearing no.C dyn of axial bearing: 630.0 kN. Screws: super conical, tightly intermeshing, counter-rotating, separating towards the top. Screw end with involute toothing acc. To DIN 5480. Thermoregulation using CIMITHERM or a two-circuit screw core thermoregulation system. Diameter (min/max): 80/156 mm. Effective screw length: 1575 mm. Max screw speed: 25 min-1. Total torque 17.5 kNm. Barrel: Three-part model. Number of barrel zones: 4 Heating power of zones 1, 2, 3, 4: 15/9/6/2x3 kW. Cooling in zones 2, 3, 4 Cooling agent distilled water with corrosion inhibitor: 26l Barrel Cooling assembly C 6 or C 12. Cooling power: C12 (12 kW) and C6 (6kW) Circulation using centrifugal pump, conveyed quantity at 2 bar. C12 (30l/min) and C6 (30l/min) Pump motor drive power. C12 (0.55kW) and C6 (0.55kW). Pump motor speed: C12 (2800 min-1) and C6 (2800 min-1). Setting pump pressure: C12 (2 bar) and C6 (2 bar). Volume of vessel: C12 (33l) and C6 (33l). Cooling of the agent by means of heat exchanger using water, min. water. Quantity required: C12 (750l/h) and C6 (750l/h). Vacuum unit: Water supply from a central water manifold Suction power of water-ring pump and a vacuum of 150 mbar: 67 m/h Pump motor, drive power. 3.6 kW Pump motor, speed: 1450 min-1 water quantity required : 360 l/h Filter. Surface: 1100 cm Water Connections: Supply to extruder: R " Runback from extruder (counter-pressureless). R 5/4" Runback from vacuum pump (counter-pressureless). R 5/4" Min. water quantity required: 3.5 m/h Min. water quantity required with screw core thermoregulation system. 4 m/h Min. water pressure 1.5 bar. Water hardness: 5-9 DH. Water Circuits: Reduction gear Distribution gear Cooling attachment Barrel cooling unit Vacuum unit Screw core thermoreg.

Used Cincinnati Twin-Screw Extruder Conical Milacron CMT 80-L. Year of production: 1995. Work hours: 39218 h D.C. shunt motor: 46kW Rating, installed and set: 1480.0 min-1 Speed: 297 Nm Torque: 0.7 kW External fan: Power Transmission: 59.19 (1) Distribution Gear Bearing no.C dyn of axial bearing: 630.0 kN. Screws: super conical, tightly intermeshing, counter-rotating, separating towards the top. Screw end with involute toothing acc. To DIN 5480. Thermoregulation using CIMITHERM or a two-circuit screw core thermoregulation system. Diameter (min/max): 80/156 mm. Effective screw length: 1575 mm. Max screw speed: 25 min-1. Total torque 17.5 kNm. Barrel: Three-part model. Number of barrel zones: 4 Heating power of zones 1, 2, 3, 4: 15/9/6/2x3 kW. Cooling in zones 2, 3, 4 Cooling agent distilled water with corrosion inhibitor: 26l Barrel Cooling assembly C 6 or C 12. Cooling power: C12 (12 kW) and C6 (6kW) Circulation using centrifugal pump, conveyed quantity at 2 bar. C12 (30l/min) and C6 (30l/min) Pump motor drive power. C12 (0.55kW) and C6 (0.55kW). Pump motor speed: C12 (2800 min-1) and C6 (2800 min-1). Setting pump pressure: C12 (2 bar) and C6 (2 bar). Volume of vessel: C12 (33l) and C6 (33l). Cooling of the agent by means of heat exchanger using water, min. water. Quantity required: C12 (750l/h) and C6 (750l/h). Vacuum unit: Water supply from a central water manifold Suction power of water-ring pump and a vacuum of 150 mbar: 67 m/h Pump motor, drive power. 3.6 kW Pump motor, speed: 1450 min-1 water quantity required : 360 l/h Filter. Surface: 1100 cm Water Connections: Supply to extruder: R " Runback from extruder (counter-pressureless). R 5/4" Runback from vacuum pump (counter-pressureless). R 5/4" Min. water quantity required: 3.5 m/h Min. water quantity required with screw core thermoregulation system. 4 m/h Min. water pressure 1.5 bar. Water hardness: 5-9 DH. Water Circuits: Reduction gear Distribution gear Cooling attachment Barrel cooling unit Vacuum unit Screw core thermoreg.

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory