Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

NBE Bulk Tote Container Unloader with Powered Roller and Cleated Incline Conveyor

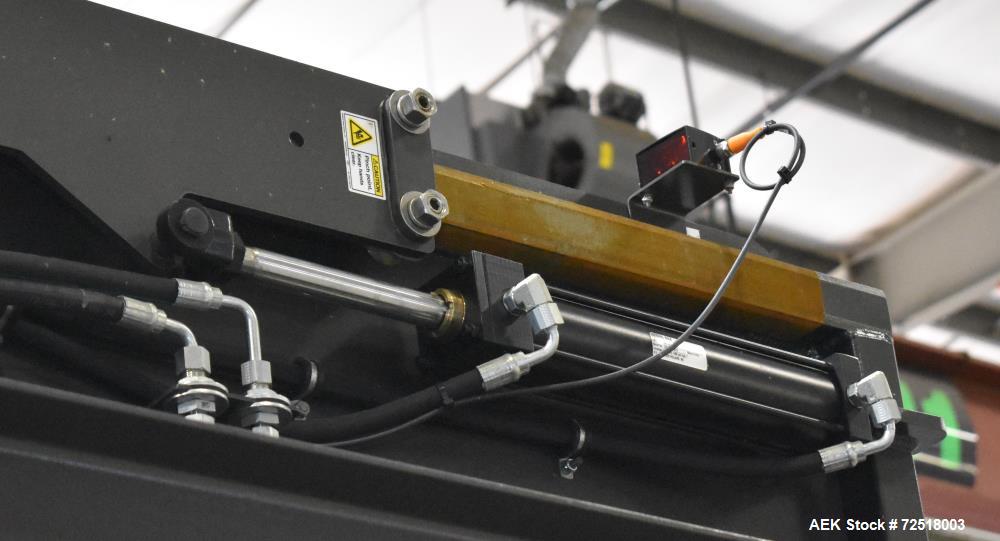

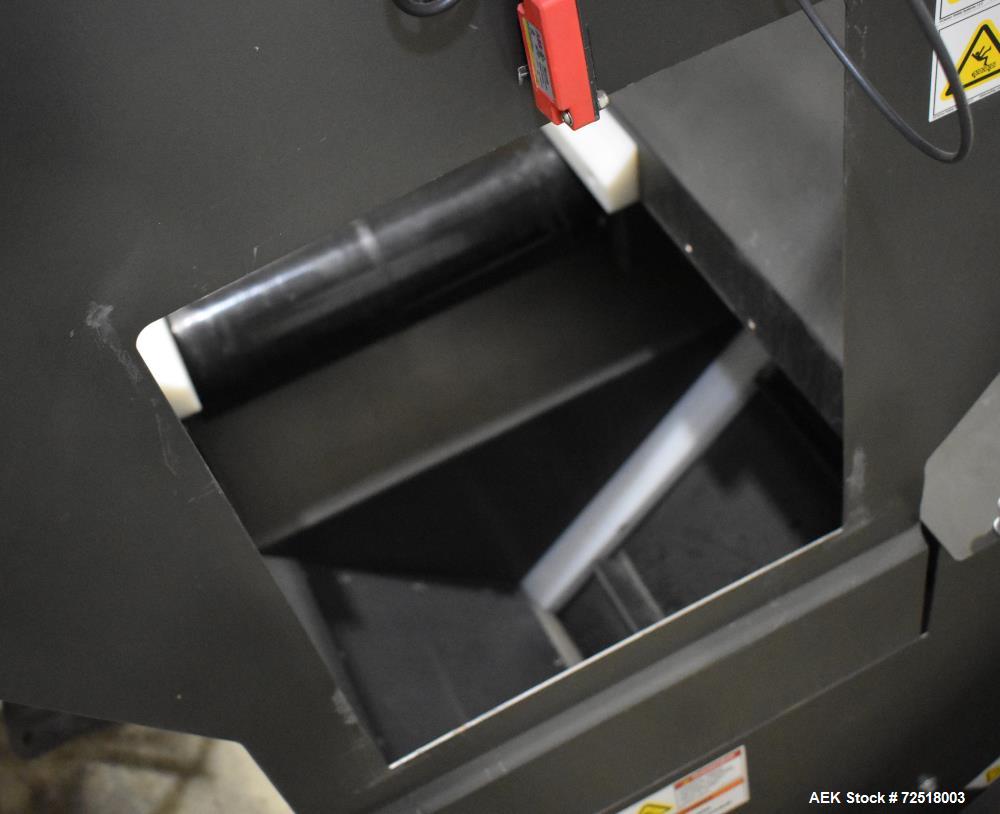

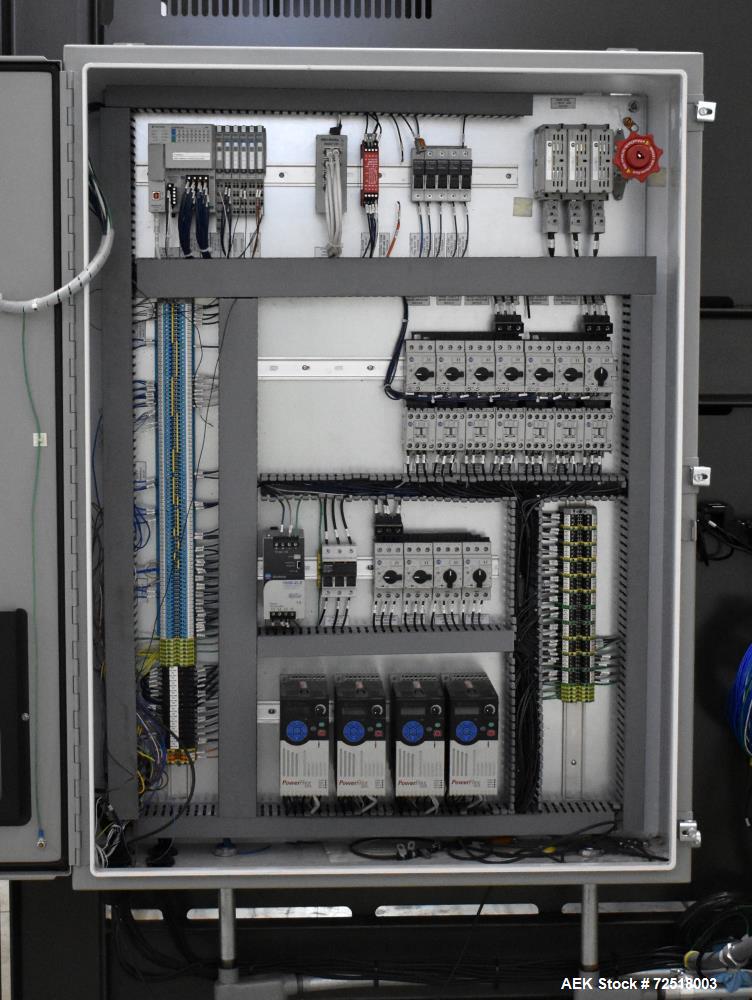

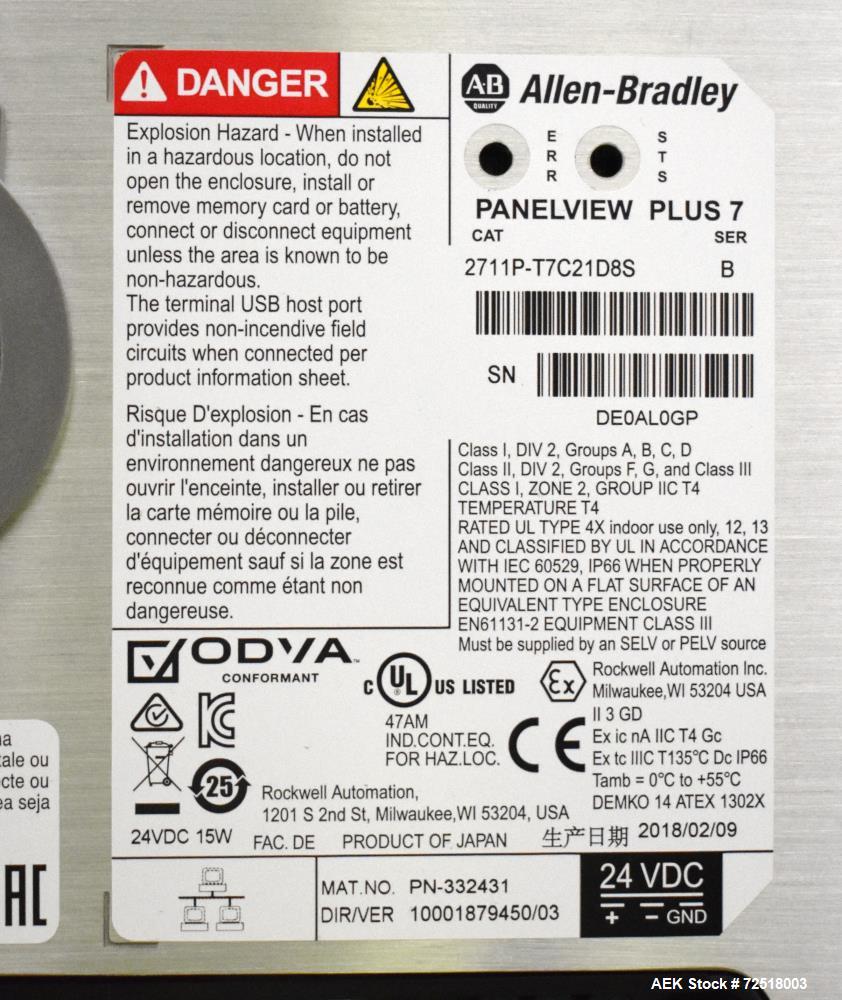

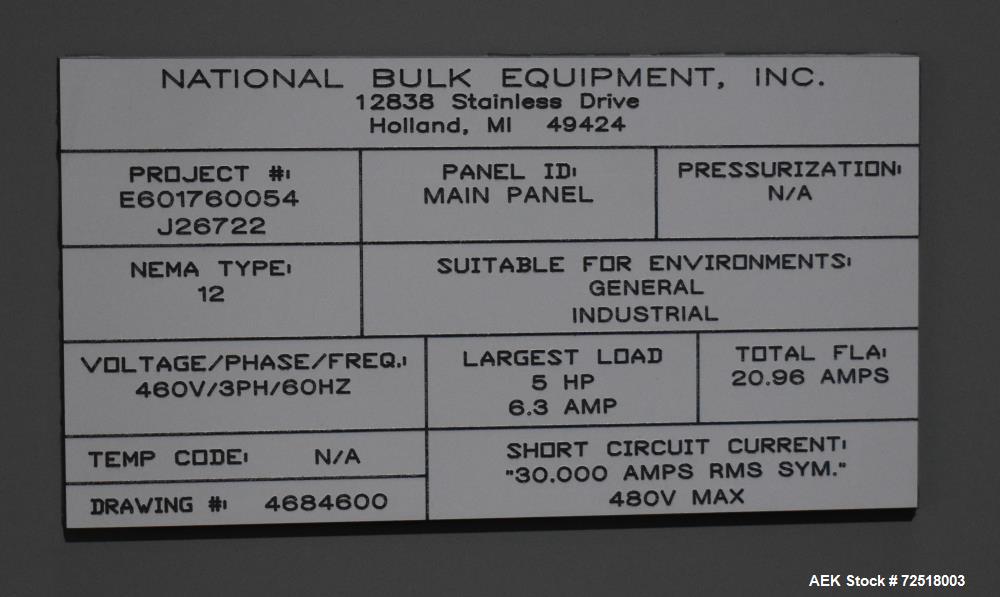

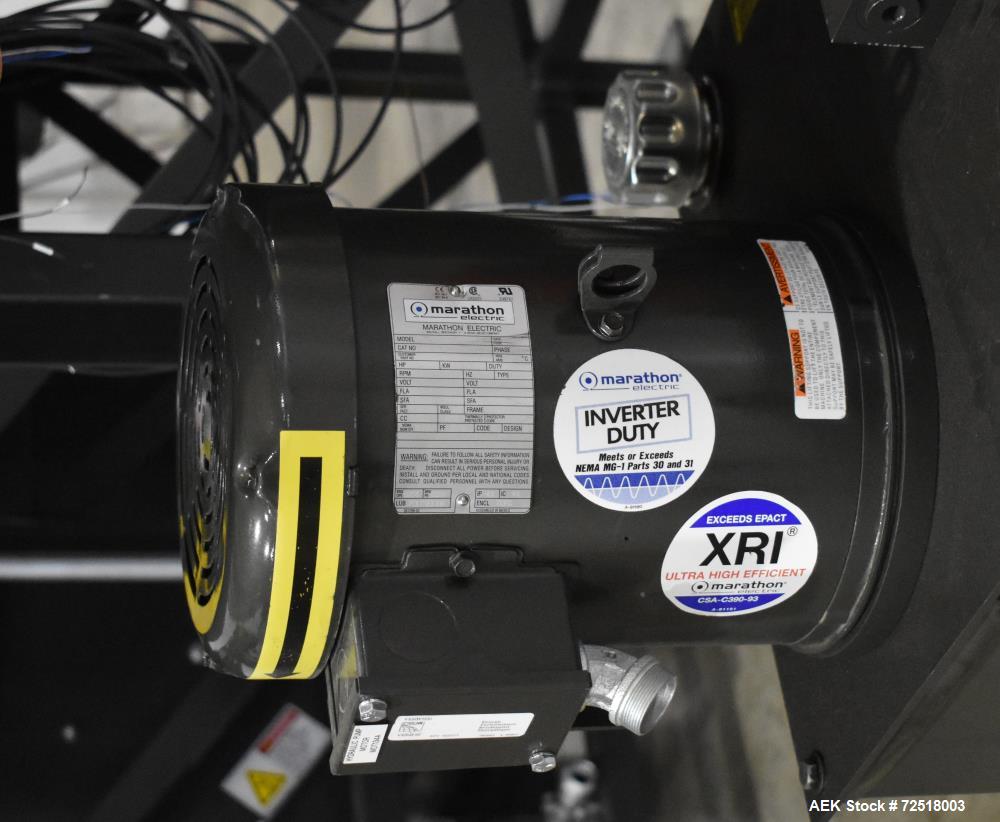

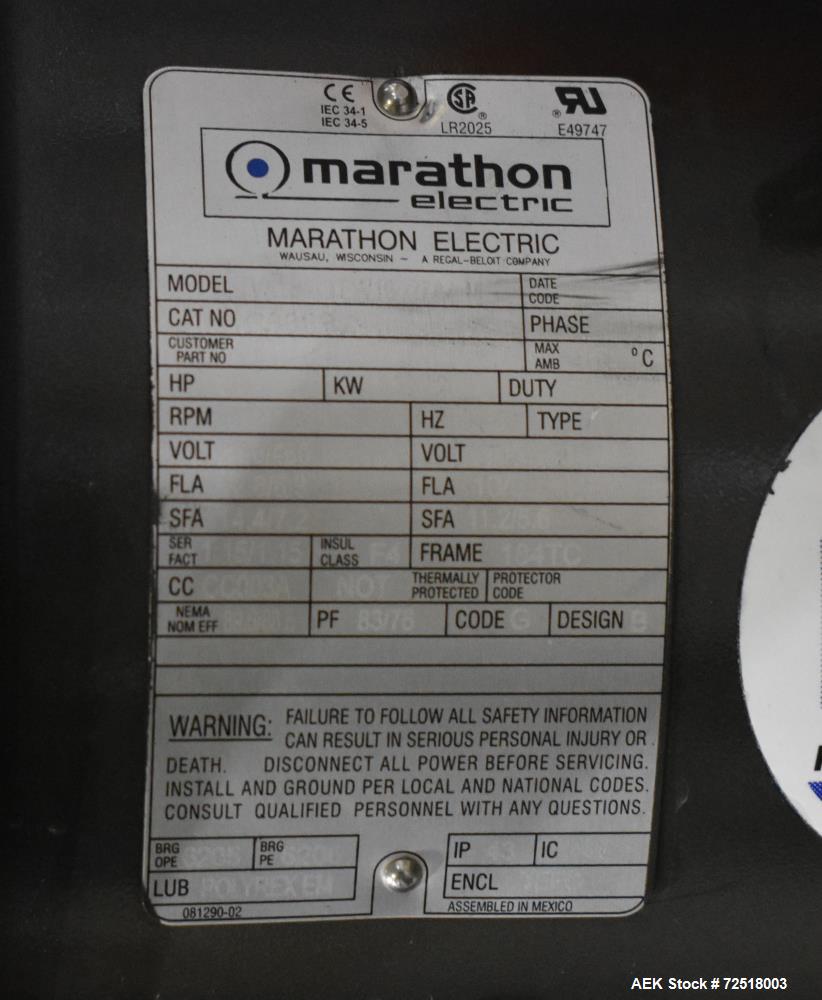

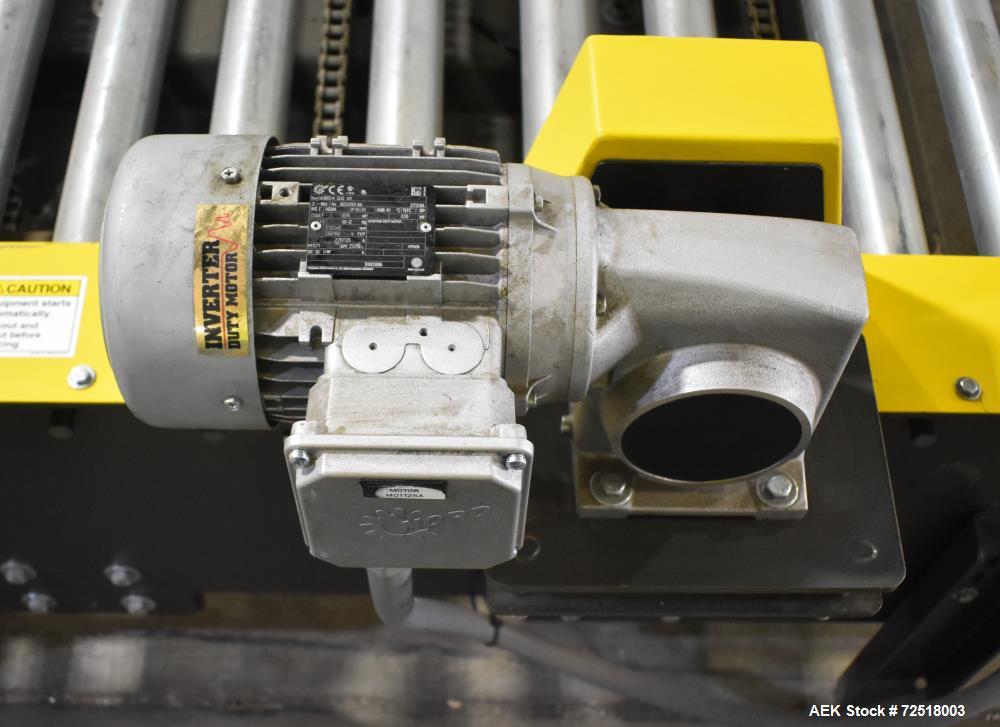

Used NBE Bulk Equipment Tote / Gaylord Container Discharge Unloading System. Designed for plastic bulk tote, 45" x 48" x 25" tall and 34" tall. Container case approximate 35" wide x 50" long x 93" tall. Load height 24", 135 degrees of rotation. Hydraulically operated tilt, with 5hp hydraulic unit. Bucket dimensions 50" wide x 56.653" deep x 94.288" tall, adjustable height retainer bar. Control panel with Allen Bradley compactlogix L18ER PLC, A/B panelview plus 7, A/B powerflex 525. Includes infeed powered roller conveyor, hopper approximate 129.5" x 53.075" x 42.25" tall with 20" wide x 133.49" long black PVC belt conveyor, 19" usable width. Incline cleated belt conveyor, 20" wide black PVC cleated belt with lacing, 14" long cleat area, 19" usable width, discharge height 51.594" tall. 3/60/460 Volt, 60 Amp.

| Manufacturer | NBENBE |

| Category | Packaging EquipmentPackaging Equipment |

| Subcategory | Material Handling - Drum Dumpers - Drum LiftsMaterial Handling - Drum Dumpers - Drum Lifts |

🏭 Manufacturer & Equipment Overview

-

Manufacturer: NBE (National Bulk Equipment)

-

Equipment Type: Tote / Gaylord Container Discharge System

-

Condition: Used

-

Function: Bulk material unloading, container tilting, and product transfer

📄 Product Description

This used NBE Gaylord Container Discharge and Unloading System is purpose-built for discharging plastic bulk totes or Gaylord containers. It features a hydraulically-operated 135° tilt bucket with adjustable height retainer bar, integrated with a robust 5 HP hydraulic power unit. Designed to handle containers up to 45" x 48" x 34" tall, this system is ideal for bulk plastics, resins, and dry granular materials.

The system is outfitted with advanced controls including an Allen Bradley CompactLogix L18ER PLC, PanelView Plus 7 HMI, and PowerFlex 525 VFD. The complete setup includes an infeed powered roller conveyor, a large hopper (129.5" x 53.075" x 42.25"), and a 20" wide black PVC cleated incline belt conveyor for consistent discharge at 51.594" height. Powered by 3-phase 460V, 60A, this high-performance system is ideal for automated material handling in plastics, food processing, and manufacturing plants.

⚙️ Technical Specifications

| Feature | Specification |

|---|---|

| Tote Size | 45" x 48" x 25"–34" Tall |

| Case Size | Approx. 35" W x 50" L x 93" H |

| Load Height | 24" |

| Tilt Angle | 135° Hydraulic Tilt |

| Hydraulic Unit | 5 HP |

| Bucket Dimensions | 50" W x 56.653" D x 94.288" H |

| Retainer Bar | Height Adjustable |

| Control Panel | Allen Bradley CompactLogix L18ER PLC |

| HMI | A/B PanelView Plus 7 |

| Drive | A/B PowerFlex 525 |

| Infeed Conveyor | Powered Roller Conveyor |

| Hopper Size | 129.5" L x 53.075" W x 42.25" H |

| Incline Conveyor | 20" W Cleated PVC Belt, 14" Cleat Area |

| Usable Belt Width | 19" |

| Discharge Height | 51.594" |

| Electrical | 3 Phase, 460V, 60A |

🧪 Applications

Perfect for unloading bulk materials from totes or Gaylords in:

-

Plastic resin/pellet handling

-

Dry chemical material discharge

-

Food ingredient bulk unloading

-

Nutraceutical powder processing

-

Grain, seed, or granular unloading

-

Rubber compound processing

-

Additive and pigment transfer

-

Recycling feed systems

-

Flexible bulk container unloading

-

Custom mixing/pre-processing lines

📦 Common Product Types Handled

-

Plastic pellets & resins

-

PVC compounds

-

Cornmeal, rice, sugar

-

Powdered or granular chemicals

-

Animal feed and supplements

-

Mineral additives

-

Rubber chips

-

Nutraceutical powders

-

Coffee beans, grains

-

Dry powder blends

Consumer Products, k-Cup, Prepackaged Food Items, Snack, Snack Foods

-

tote unloader

-

NBE system

-

bulk equipment

-

cleated conveyor

-

container tilt

-

hydraulic unloader

-

gaylord dumper

-

used tote loader

-

resin unloading

-

incline conveyor

-

NBE tote discharge system

-

used gaylord container unloader

-

hydraulically tilting tote dumper

-

Allen Bradley PLC conveyor system

-

resin tote discharge equipment

-

PVC cleated incline conveyor

-

industrial tote unloading machine

-

powered roller infeed system

-

container unloader with HMI

-

bulk discharge automation system

-

used NBE tote and gaylord container discharge system with PLC control

-

135 degree hydraulic tilt bulk unloading system

-

Allen Bradley controlled tote discharge machine with cleated conveyor

-

plastic resin tote dumper with adjustable retainer bar

-

bulk powder tote unloader with powered infeed and incline conveyor

-

food-grade gaylord discharge system with hopper and PVC belt

-

used 5HP hydraulic tilt discharge station for bulk materials

-

incline belt conveyor system for tote-fed production lines

-

container discharge equipment with 20 inch PVC cleated belt

-

complete unloading system for bulk plastic containers

-

bulk container unloader

-

tote discharge system

-

gaylord dumper machine

-

cleated conveyor system

-

bulk material handling

-

hydraulically tilting dumper

-

plastic resin handling

-

incline conveyor belt

-

used discharge equipment

-

industrial unloader system

-

buy tote unloader

-

used bulk discharge system

-

NBE dumper for sale

-

sell container unloader

-

purchase gaylord tilt system

-

unload resin from totes

-

buy hydraulic discharge unit

-

incline conveyor system for sale

-

automated tote dumper

-

material handling equipment used

Used NBE Bulk Equipment Tote / Gaylord Container Discharge Unloading System. Designed for plastic bulk tote, 45" x 48" x 25" tall and 34" tall. Container case approximate 35" wide x 50" long x 93" tall. Load height 24", 135 degrees of rotation. Hydraulically operated tilt, with 5hp hydraulic unit. Bucket dimensions 50" wide x 56.653" deep x 94.288" tall, adjustable height retainer bar. Control panel with Allen Bradley compactlogix L18ER PLC, A/B panelview plus 7, A/B powerflex 525. Includes infeed powered roller conveyor, hopper approximate 129.5" x 53.075" x 42.25" tall with 20" wide x 133.49" long black PVC belt conveyor, 19" usable width. Incline cleated belt conveyor, 20" wide black PVC cleated belt with lacing, 14" long cleat area, 19" usable width, discharge height 51.594" tall. 3/60/460 Volt, 60 Amp.

🏭 Manufacturer & Equipment Overview

-

Manufacturer: NBE (National Bulk Equipment)

-

Equipment Type: Tote / Gaylord Container Discharge System

-

Condition: Used

-

Function: Bulk material unloading, container tilting, and product transfer

📄 Product Description

This used NBE Gaylord Container Discharge and Unloading System is purpose-built for discharging plastic bulk totes or Gaylord containers. It features a hydraulically-operated 135° tilt bucket with adjustable height retainer bar, integrated with a robust 5 HP hydraulic power unit. Designed to handle containers up to 45" x 48" x 34" tall, this system is ideal for bulk plastics, resins, and dry granular materials.

The system is outfitted with advanced controls including an Allen Bradley CompactLogix L18ER PLC, PanelView Plus 7 HMI, and PowerFlex 525 VFD. The complete setup includes an infeed powered roller conveyor, a large hopper (129.5" x 53.075" x 42.25"), and a 20" wide black PVC cleated incline belt conveyor for consistent discharge at 51.594" height. Powered by 3-phase 460V, 60A, this high-performance system is ideal for automated material handling in plastics, food processing, and manufacturing plants.

⚙️ Technical Specifications

| Feature | Specification |

|---|---|

| Tote Size | 45" x 48" x 25"–34" Tall |

| Case Size | Approx. 35" W x 50" L x 93" H |

| Load Height | 24" |

| Tilt Angle | 135° Hydraulic Tilt |

| Hydraulic Unit | 5 HP |

| Bucket Dimensions | 50" W x 56.653" D x 94.288" H |

| Retainer Bar | Height Adjustable |

| Control Panel | Allen Bradley CompactLogix L18ER PLC |

| HMI | A/B PanelView Plus 7 |

| Drive | A/B PowerFlex 525 |

| Infeed Conveyor | Powered Roller Conveyor |

| Hopper Size | 129.5" L x 53.075" W x 42.25" H |

| Incline Conveyor | 20" W Cleated PVC Belt, 14" Cleat Area |

| Usable Belt Width | 19" |

| Discharge Height | 51.594" |

| Electrical | 3 Phase, 460V, 60A |

🧪 Applications

Perfect for unloading bulk materials from totes or Gaylords in:

-

Plastic resin/pellet handling

-

Dry chemical material discharge

-

Food ingredient bulk unloading

-

Nutraceutical powder processing

-

Grain, seed, or granular unloading

-

Rubber compound processing

-

Additive and pigment transfer

-

Recycling feed systems

-

Flexible bulk container unloading

-

Custom mixing/pre-processing lines

📦 Common Product Types Handled

-

Plastic pellets & resins

-

PVC compounds

-

Cornmeal, rice, sugar

-

Powdered or granular chemicals

-

Animal feed and supplements

-

Mineral additives

-

Rubber chips

-

Nutraceutical powders

-

Coffee beans, grains

-

Dry powder blends

Consumer Products, k-Cup, Prepackaged Food Items, Snack, Snack Foods

| Manufacturer | NBE |

| Category | Packaging Equipment |

| Subcategory | Material Handling - Drum Dumpers - Drum Lifts |

-

tote unloader

-

NBE system

-

bulk equipment

-

cleated conveyor

-

container tilt

-

hydraulic unloader

-

gaylord dumper

-

used tote loader

-

resin unloading

-

incline conveyor

-

NBE tote discharge system

-

used gaylord container unloader

-

hydraulically tilting tote dumper

-

Allen Bradley PLC conveyor system

-

resin tote discharge equipment

-

PVC cleated incline conveyor

-

industrial tote unloading machine

-

powered roller infeed system

-

container unloader with HMI

-

bulk discharge automation system

-

used NBE tote and gaylord container discharge system with PLC control

-

135 degree hydraulic tilt bulk unloading system

-

Allen Bradley controlled tote discharge machine with cleated conveyor

-

plastic resin tote dumper with adjustable retainer bar

-

bulk powder tote unloader with powered infeed and incline conveyor

-

food-grade gaylord discharge system with hopper and PVC belt

-

used 5HP hydraulic tilt discharge station for bulk materials

-

incline belt conveyor system for tote-fed production lines

-

container discharge equipment with 20 inch PVC cleated belt

-

complete unloading system for bulk plastic containers

-

bulk container unloader

-

tote discharge system

-

gaylord dumper machine

-

cleated conveyor system

-

bulk material handling

-

hydraulically tilting dumper

-

plastic resin handling

-

incline conveyor belt

-

used discharge equipment

-

industrial unloader system

-

buy tote unloader

-

used bulk discharge system

-

NBE dumper for sale

-

sell container unloader

-

purchase gaylord tilt system

-

unload resin from totes

-

buy hydraulic discharge unit

-

incline conveyor system for sale

-

automated tote dumper

-

material handling equipment used

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory

.jpg)