Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: [email protected]

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

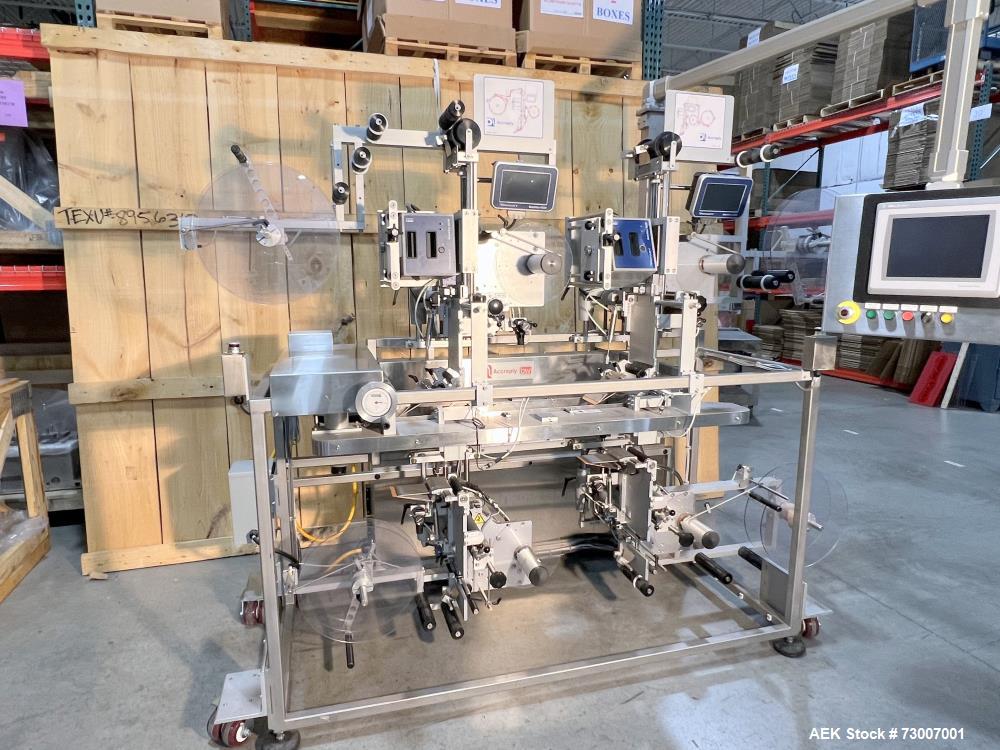

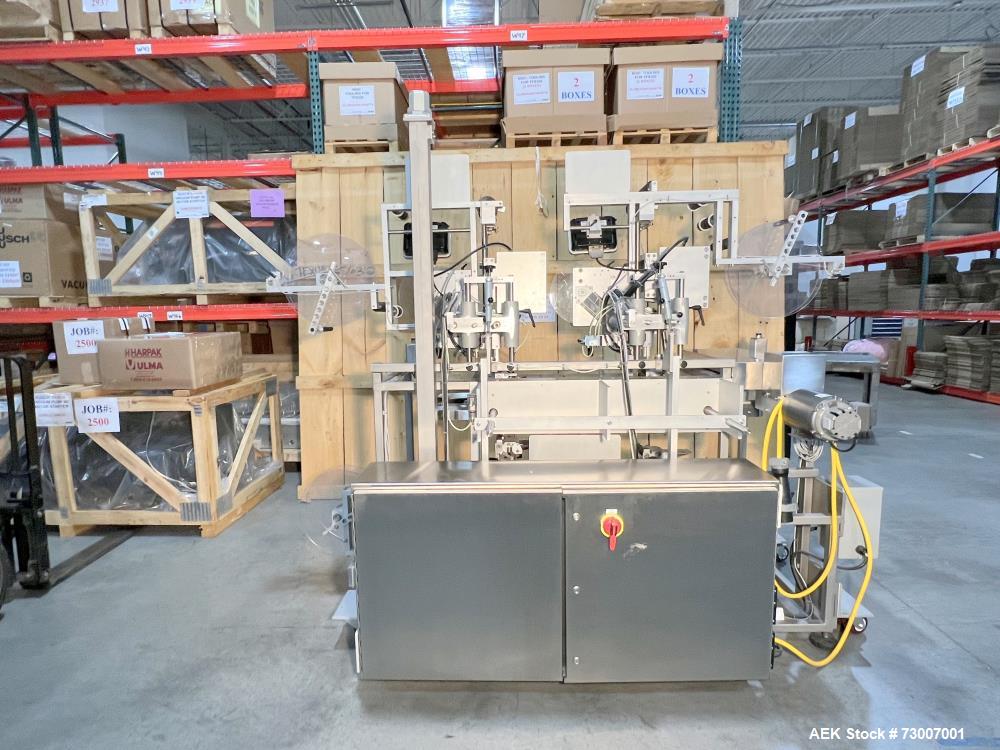

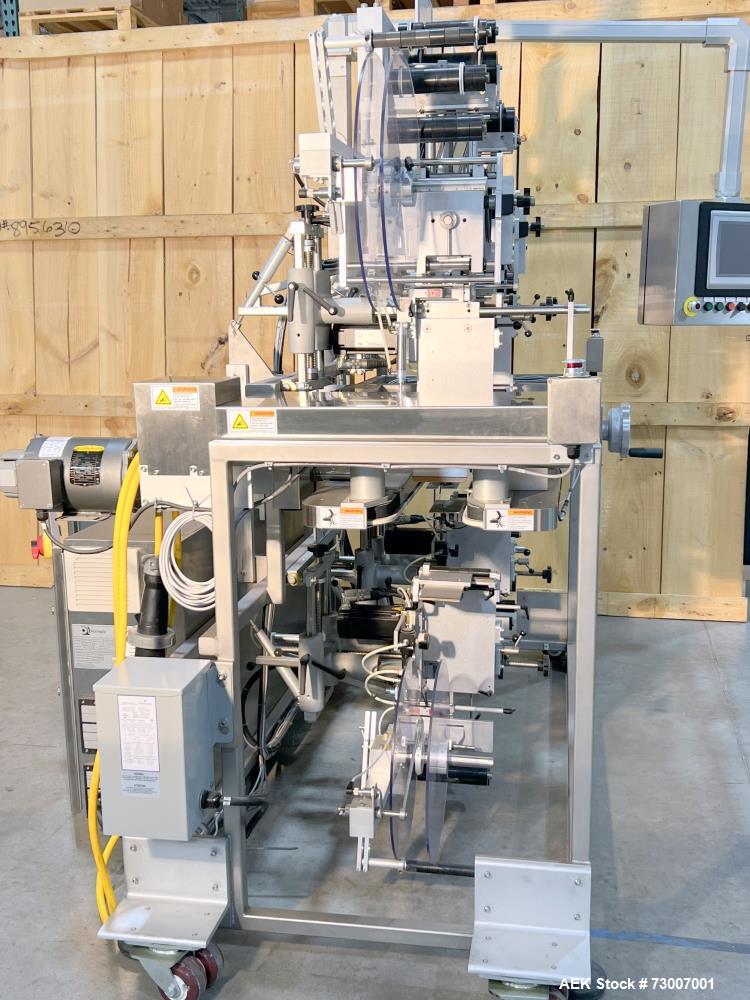

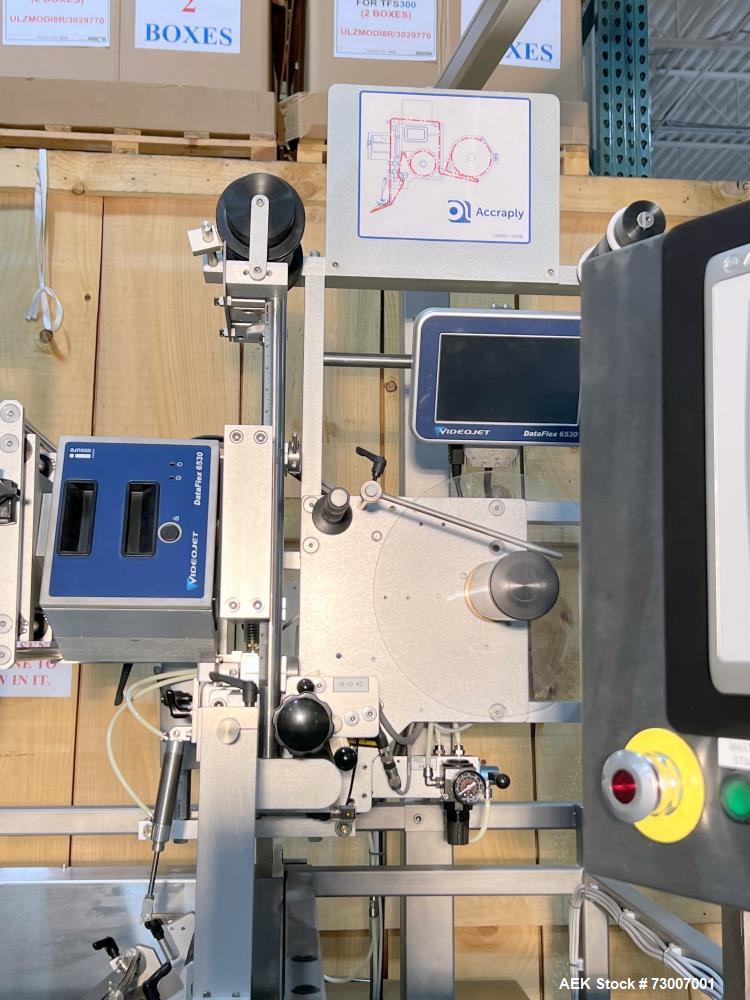

Used Accraply Model 350B-S Series Top and Bottom Labeling System. Capable of up to 120 products per minute depending on application. Special purpose labeling system developed specifically to apply to...

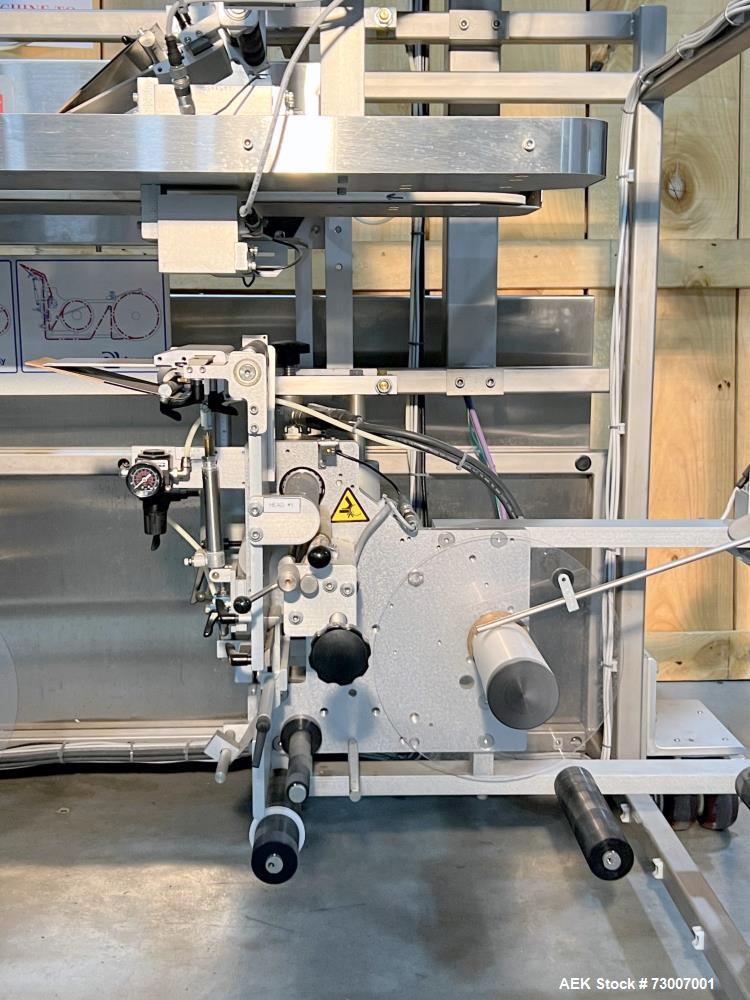

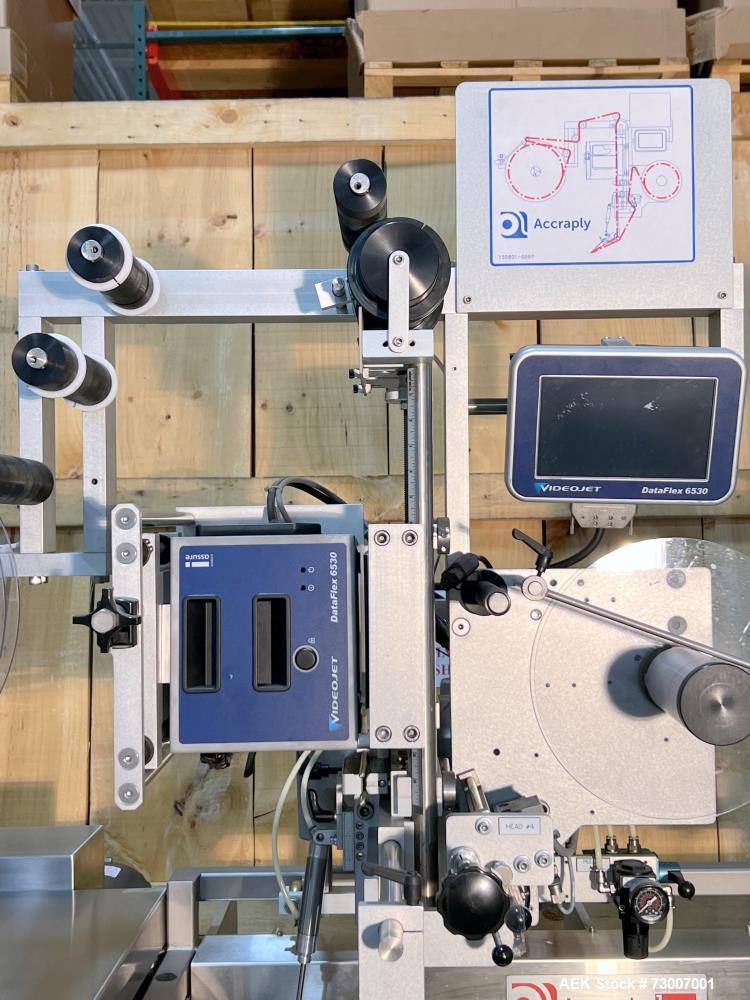

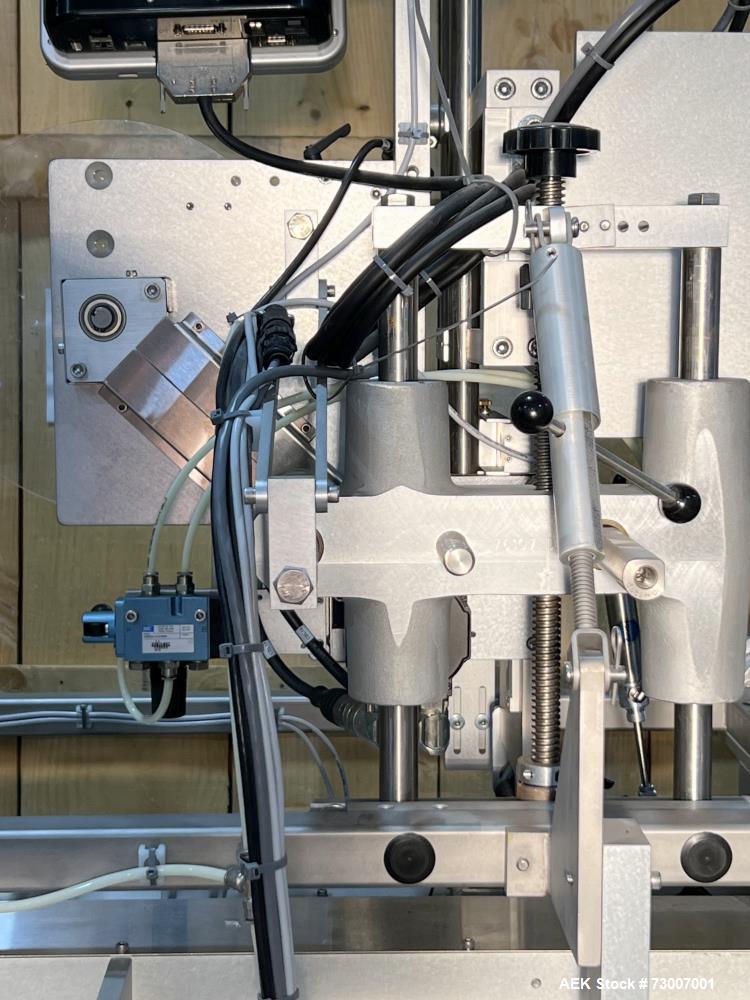

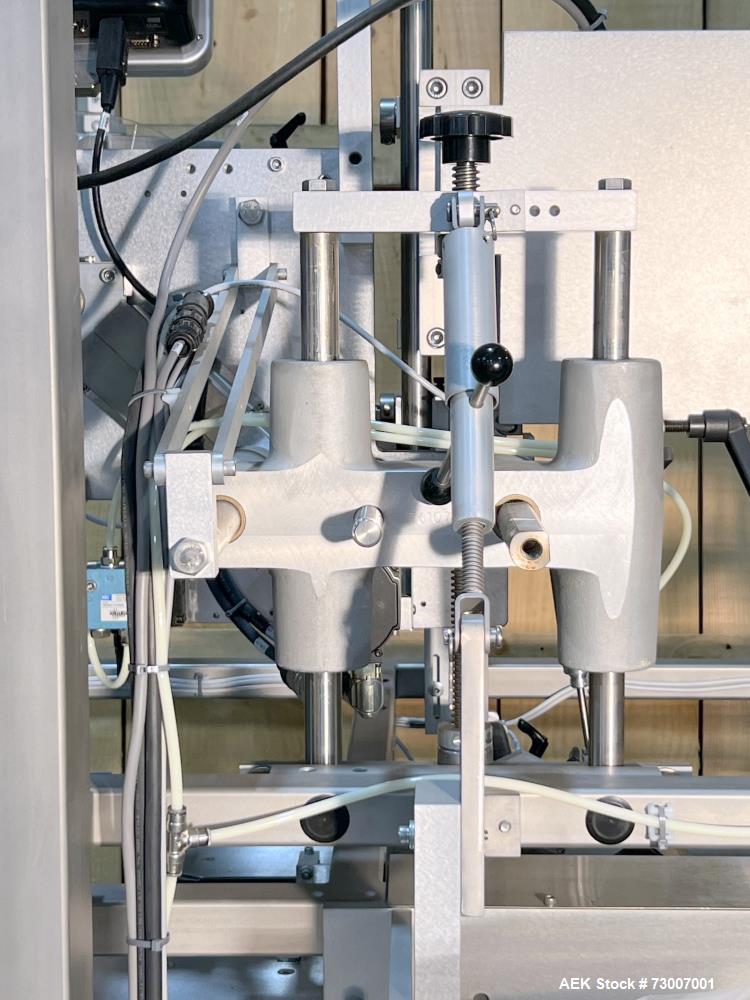

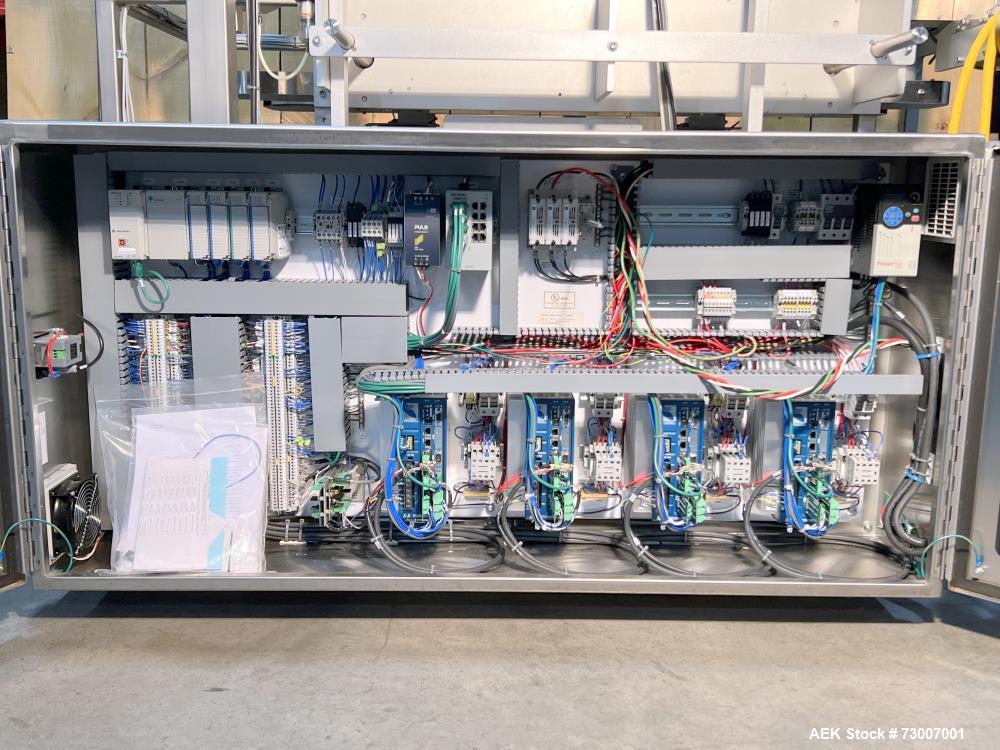

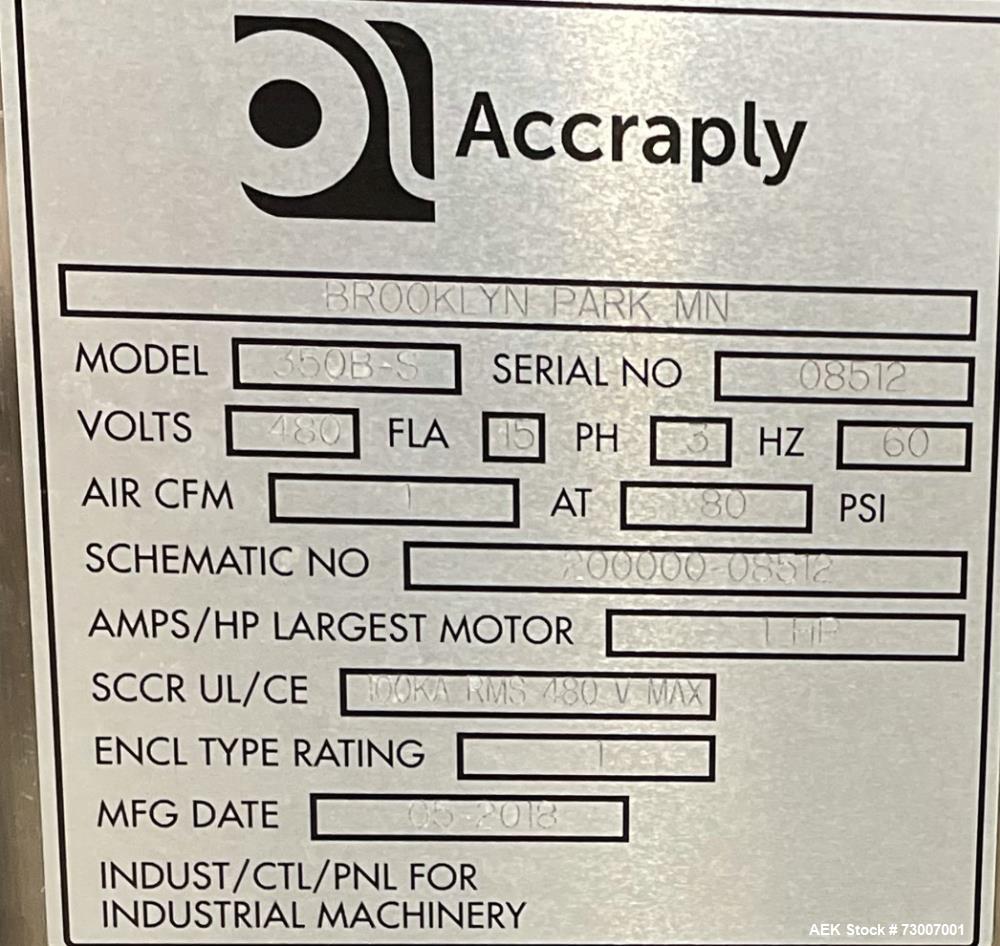

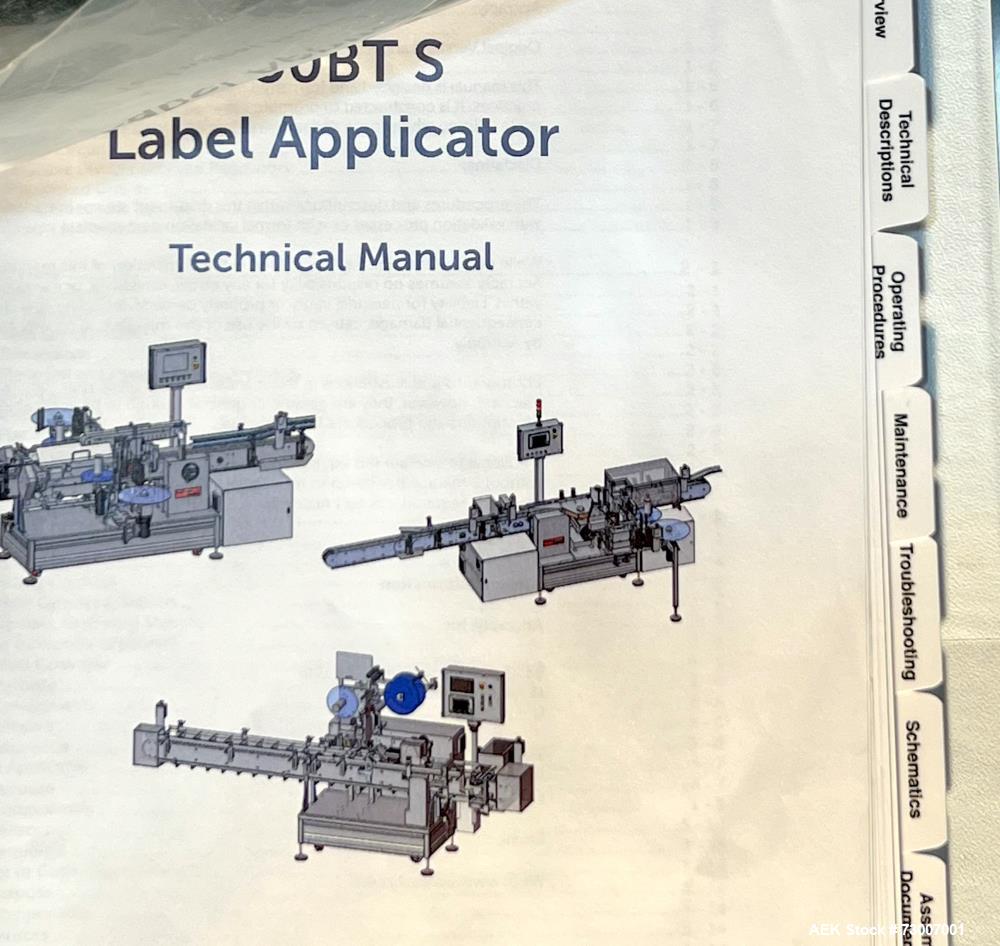

Used Accraply Model 350B-S Series Top and Bottom Labeling System. Capable of up to 120 products per minute depending on application. Special purpose labeling system developed specifically to apply top and bottom panel labels to a wide variety of products. Heavy Gauge Stainless Steel Base Frame with Adjustable Leveling Feet and Casters; Adjustable variable speed dual side belt conveyor for greater product control; Centralized system control panel with CTC color touch-screen, product and label counters, and rate meter; Convenient, centralized pivoting operator interface controls with stack light; Drop-in label threading with quick release rewind reel core; Dual Side-Belt Product Transport with Adjustable Speed Control; (2) Photoelectric Product Sensors (Primary, Secondary); (4) ACCRAPLY Servo SP10 Applicators with (2) Mounts for Bottom Labeling; (2) Mounts for Top Labeling; (2) Rod-Style Apron Upgrades for Top Applicators; (2) VideoJet Dataflex 6530 Thermal Transfer Printer (Top Label Only); (4) Air Assisted Label Peeler Assemblies with (4) SSTL Peeler Plates (peelers actuate for label threading); (4) Label Applicator Convenience Package, Includes: Low Label Roll and Broken Label Web Detection; (1) Centralized System Control Panel with Stainless Steel NEMA; 12 HMI Enclosure; Color Touch Screen Operator Interface; 10" Allen Bradley PanelView Plus 1000 Rate Meter - (displays part per minute rate); Remote Jog Switch for Upstream Heads; (1) Main Electrical Enclosure (UL 508A Enclosure); Stainless Steel NEMA 12 Main Enclosure; NEMA 12 Fan Kit Water Tight Connections on Main Enclosure and Label Heads (as Applicable ); Allen Bradley CompactLogix PLC 1769-L33E Allen Bradley 525 VFD. Built 2018.

Food Products, General Manufacturing, Generic Pharmaceuticals, Labels, Medical Products, Pharmaceutical Products

"Dealing with Aaron is an easy and enjoyable process"

"Aaron Equipment is always my first call for used process equipment. Their inventory and customer service has ensured successful project results every time. Thanks y’all!"

"I have purchased all different types of equipment from Aaron Equipment over the last 10 years and have always been 100% happy with not only the equipment but with their customer service!"

"Working with Aaron Equipment Company was as easy as it gets."

"It is a pleasure to work with AEK and I would recommend them as an equipment supplier."

"The partnership we enjoy with Aaron has helped our business to be what it is today – thank you guys!”

"I will definitely use Aaron Equipment in the future."

"Aaron’s customer service indicates that they want long term partnerships and that is something we especially appreciate."

"I really value shopping for used equipment from Aaron Equipment Company because the information they present is accurate, their prices fair and their customer service is the best…Highly recommend."

"This is my first time using Aaron Equipment to purchase equipment. They were easy to work with and things were done quickly and efficiently. I will be a repeat customer when the need arises. This is a trustworthy company that delivers what they advertise."

"I have purchased multiple pieces of equipment through Aaron equipment over the past 15 years. The staff has been very knowledgeable on every request & have spent countless hours ensuring that the equipment I was purchasing met my expectations."

"I have been doing business with Aaron equipment for many years. This year I had the need for some used equipment in a new business Venture. I got in touch with Ryan Davies. I could not be happier with the response and honesty exhibited by him. Dealing with them was a pleasure and everything was as represented. Fair an Honest is how I would describe them."

“Aaron Equipment was very easy to get into contact with and get a price on a un-used chiller they were selling. The process was seamless and very easy on our end and we had the equipment much faster than going out for bid on it to multiple vendors and we able to come in under budget on the project.”

"Aaron Equipment is always my first call for used process equipment. Their inventory and customer service has ensured successful project results every time. Thanks y’all!"

"I have purchased all different types of equipment from Aaron Equipment over the last 10 years and have always been 100% happy with not only the equipment but with their customer service!"

"Working with Aaron Equipment Company was as easy as it gets."

"It is a pleasure to work with AEK and I would recommend them as an equipment supplier."

"The partnership we enjoy with Aaron has helped our business to be what it is today – thank you guys!”

"I will definitely use Aaron Equipment in the future."

"Aaron’s customer service indicates that they want long term partnerships and that is something we especially appreciate."

"I really value shopping for used equipment from Aaron Equipment Company because the information they present is accurate, their prices fair and their customer service is the best…Highly recommend."

Used Accraply Model 350B-S Series Top and Bottom Labeling System. Capable of up to 120 products per minute depending on application. Special purpose labeling system developed specifically to apply top and bottom panel labels to a wide variety of products. Heavy Gauge Stainless Steel Base Frame with Adjustable Leveling Feet and Casters; Adjustable variable speed dual side belt conveyor for greater product control; Centralized system control panel with CTC color touch-screen, product and label counters, and rate meter; Convenient, centralized pivoting operator interface controls with stack light; Drop-in label threading with quick release rewind reel core; Dual Side-Belt Product Transport with Adjustable Speed Control; (2) Photoelectric Product Sensors (Primary, Secondary); (4) ACCRAPLY Servo SP10 Applicators with (2) Mounts for Bottom Labeling; (2) Mounts for Top Labeling; (2) Rod-Style Apron Upgrades for Top Applicators; (2) VideoJet Dataflex 6530 Thermal Transfer Printer (Top Label Only); (4) Air Assisted Label Peeler Assemblies with (4) SSTL Peeler Plates (peelers actuate for label threading); (4) Label Applicator Convenience Package, Includes: Low Label Roll and Broken Label Web Detection; (1) Centralized System Control Panel with Stainless Steel NEMA; 12 HMI Enclosure; Color Touch Screen Operator Interface; 10" Allen Bradley PanelView Plus 1000 Rate Meter - (displays part per minute rate); Remote Jog Switch for Upstream Heads; (1) Main Electrical Enclosure (UL 508A Enclosure); Stainless Steel NEMA 12 Main Enclosure; NEMA 12 Fan Kit Water Tight Connections on Main Enclosure and Label Heads (as Applicable ); Allen Bradley CompactLogix PLC 1769-L33E Allen Bradley 525 VFD. Built 2018.

Food Products, General Manufacturing, Generic Pharmaceuticals, Labels, Medical Products, Pharmaceutical Products

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory

.jpg)