Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Buy a used Matrix Pro Series 20135R vertical form fill seal machine. High-speed packaging for dry goods. Includes scale. Contact us today!

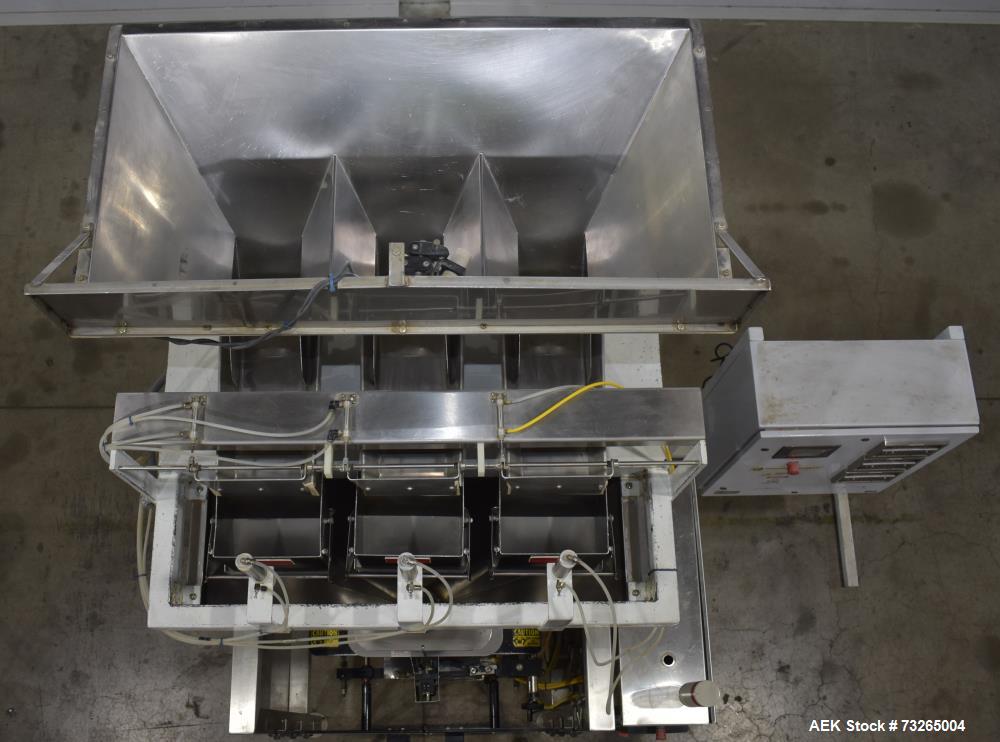

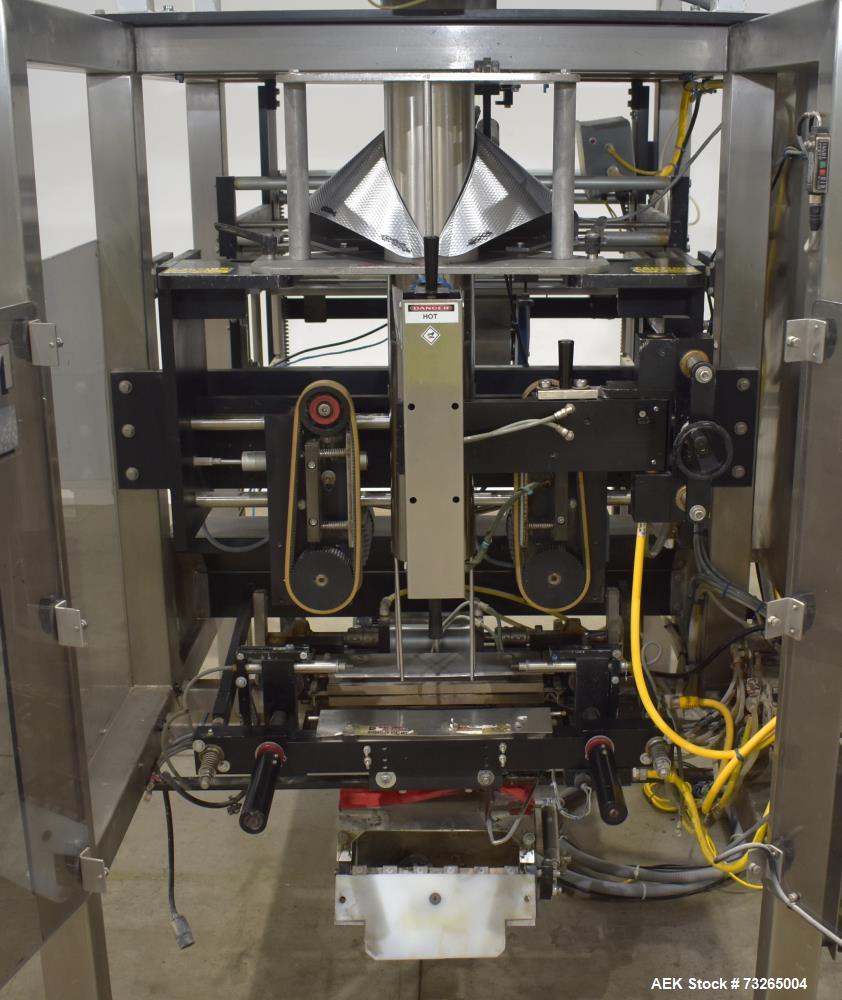

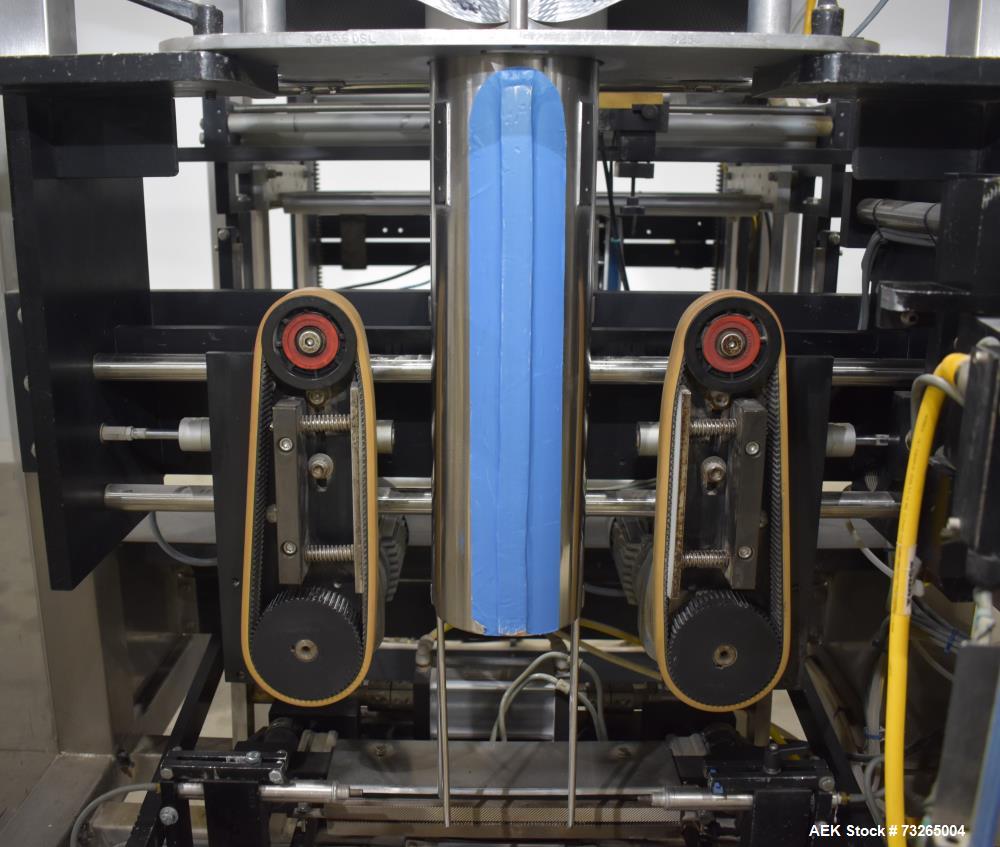

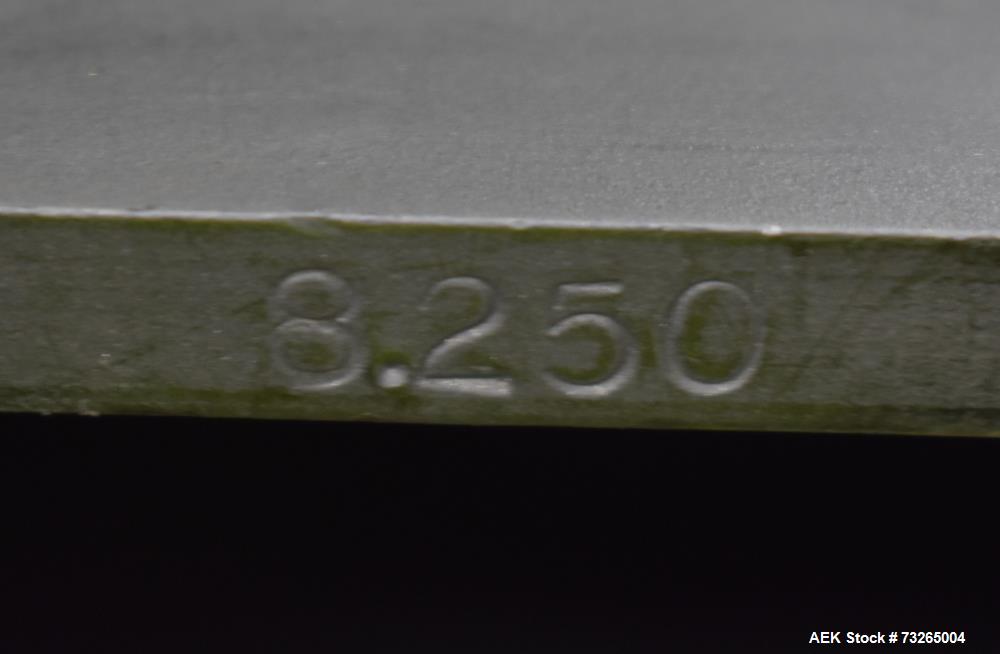

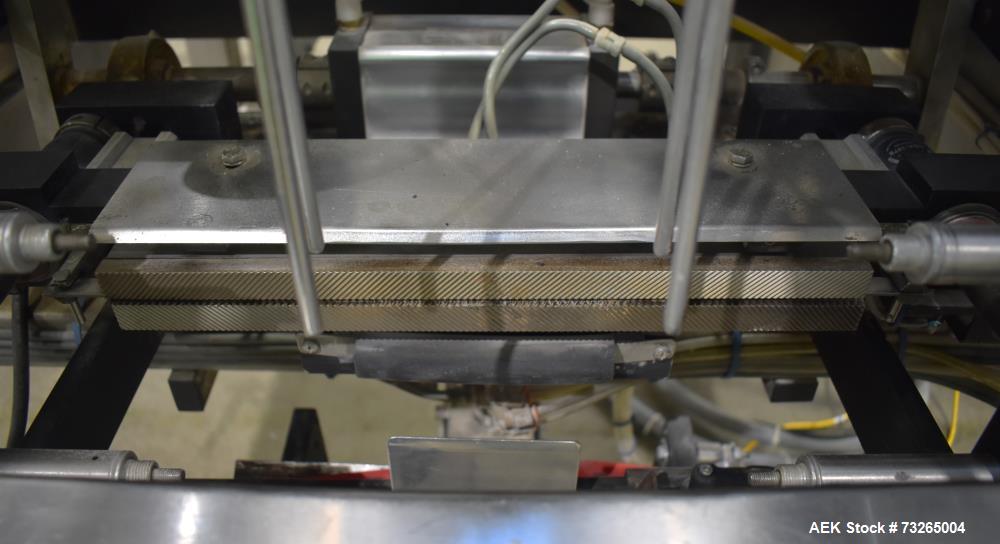

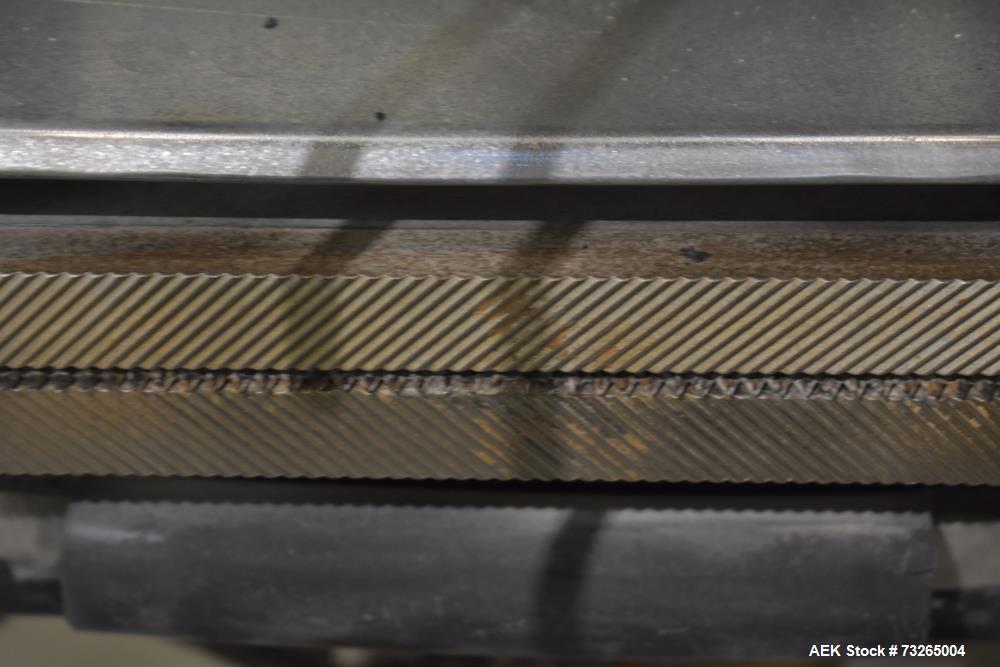

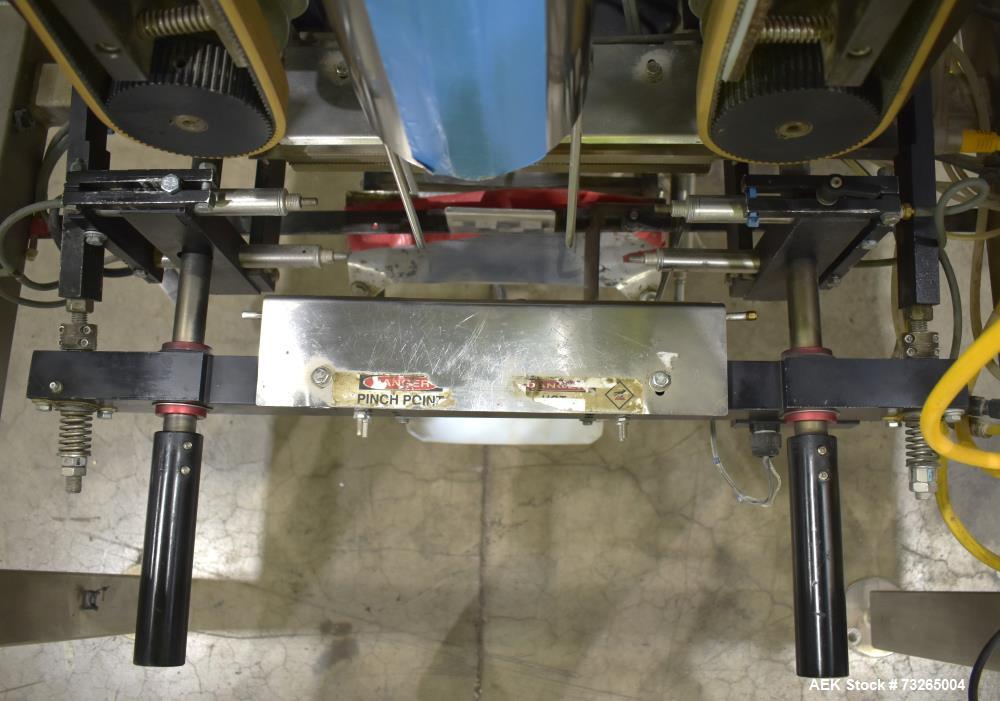

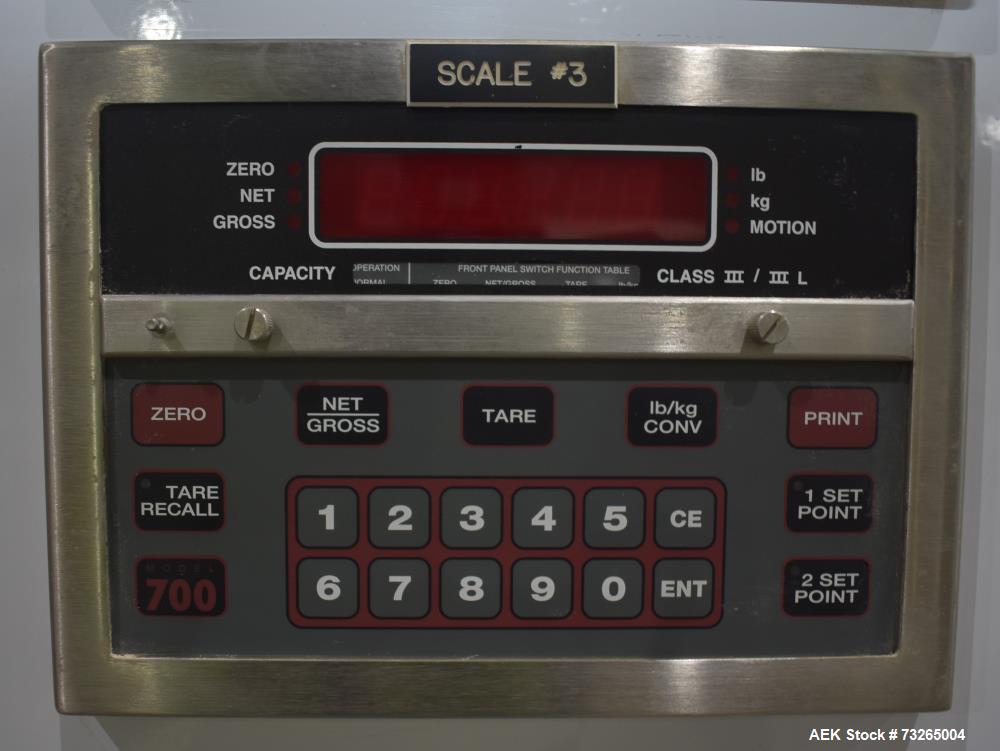

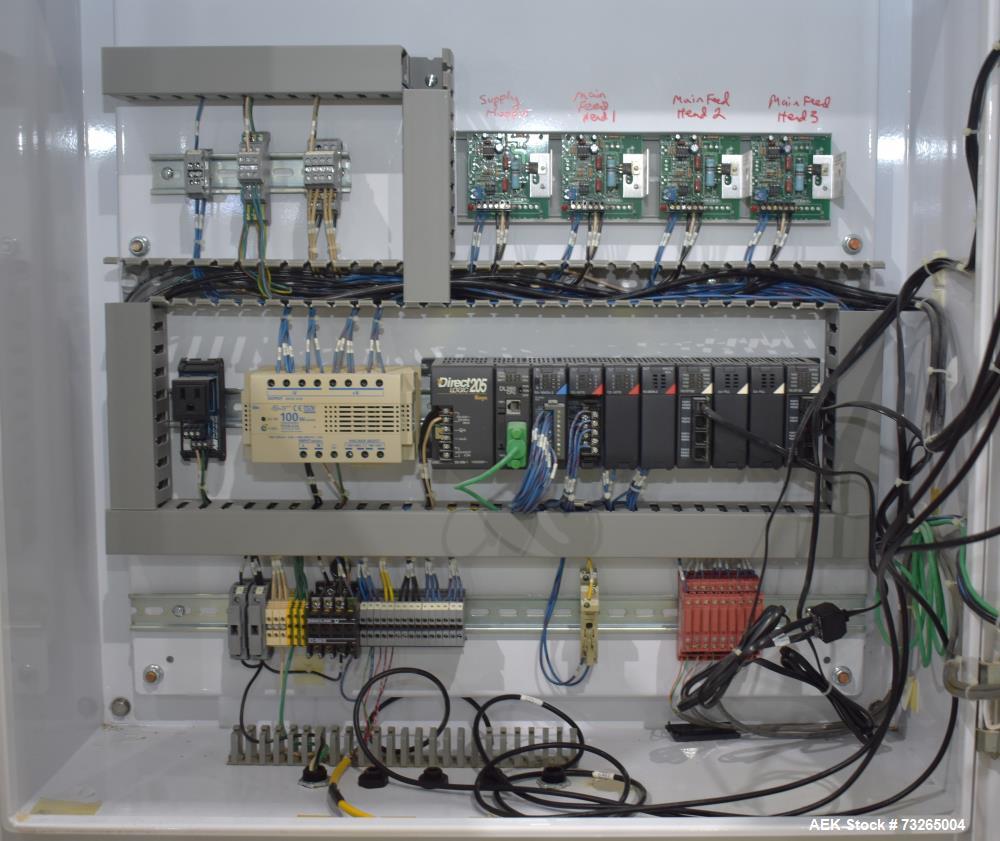

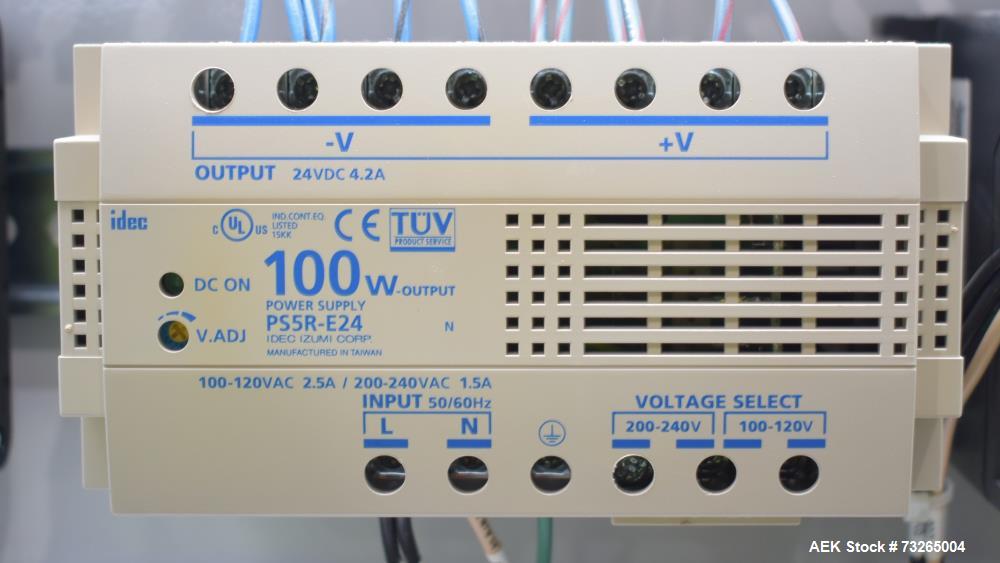

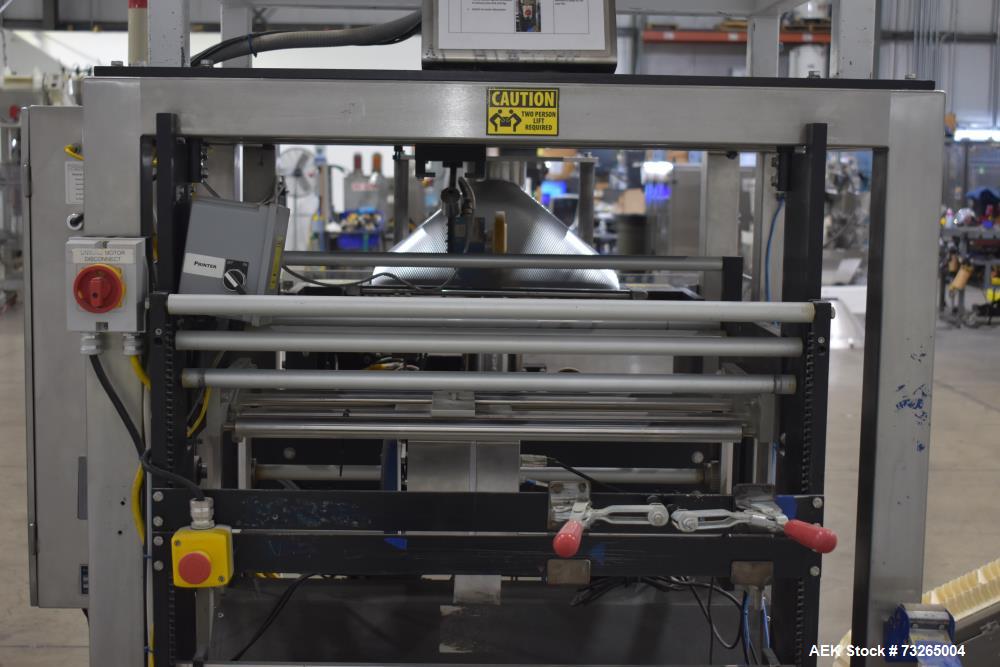

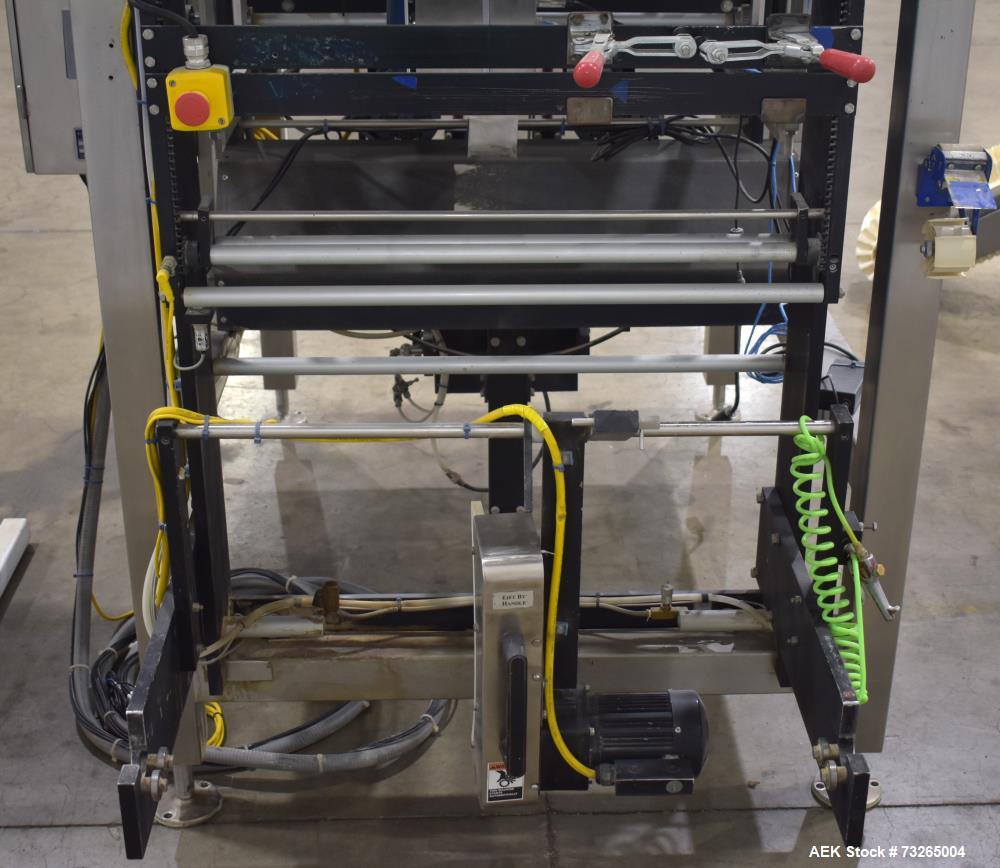

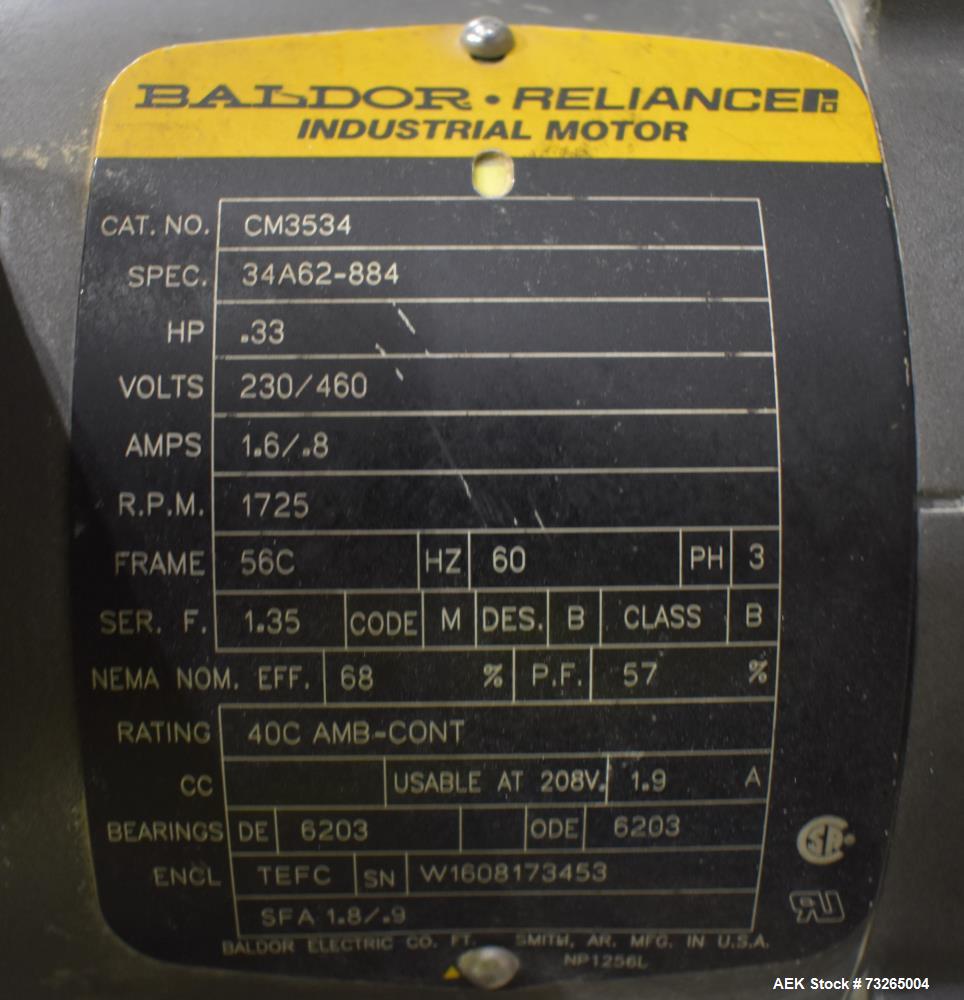

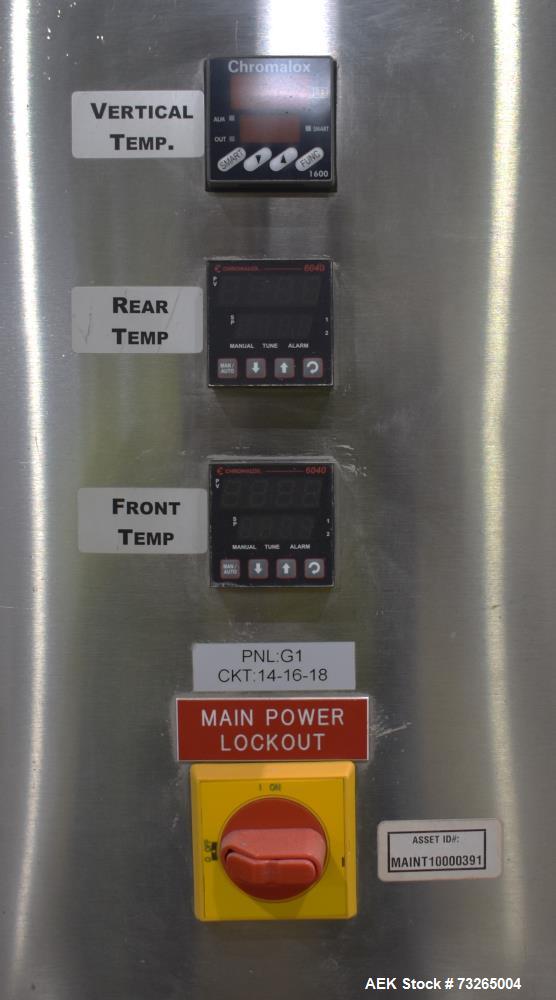

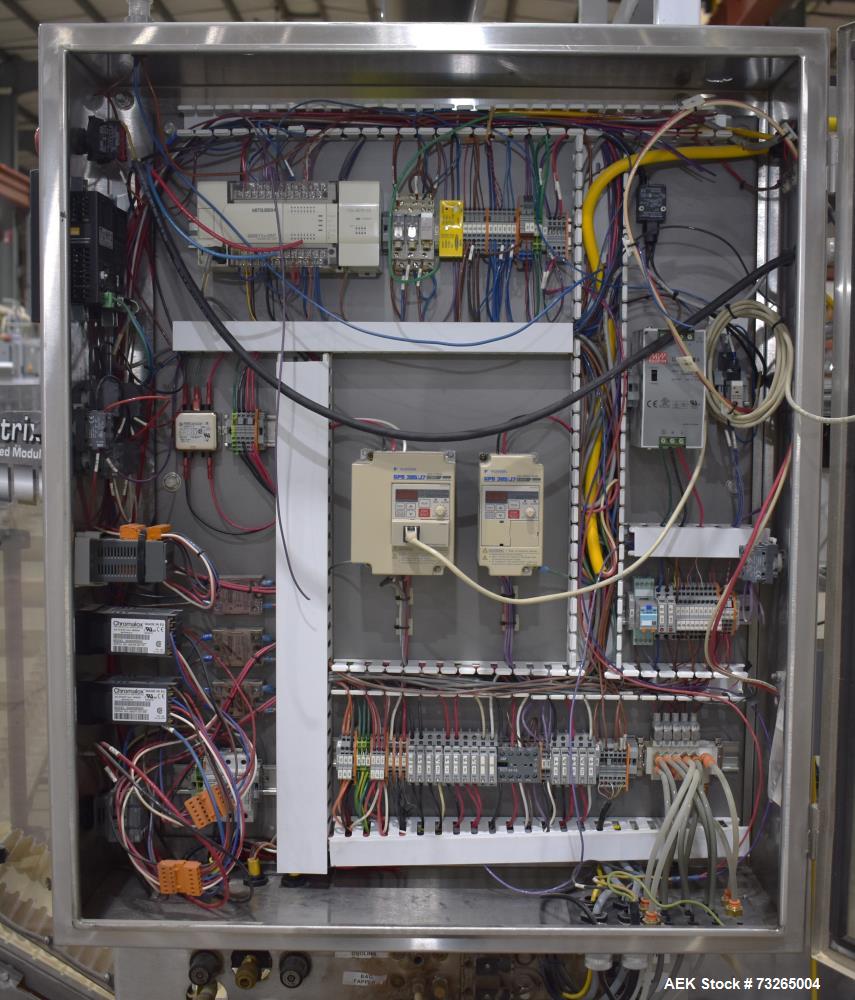

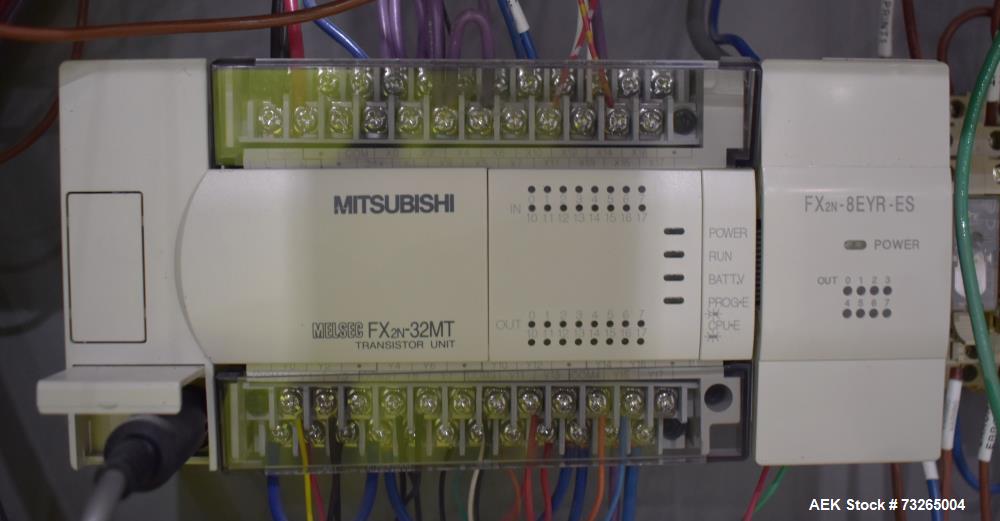

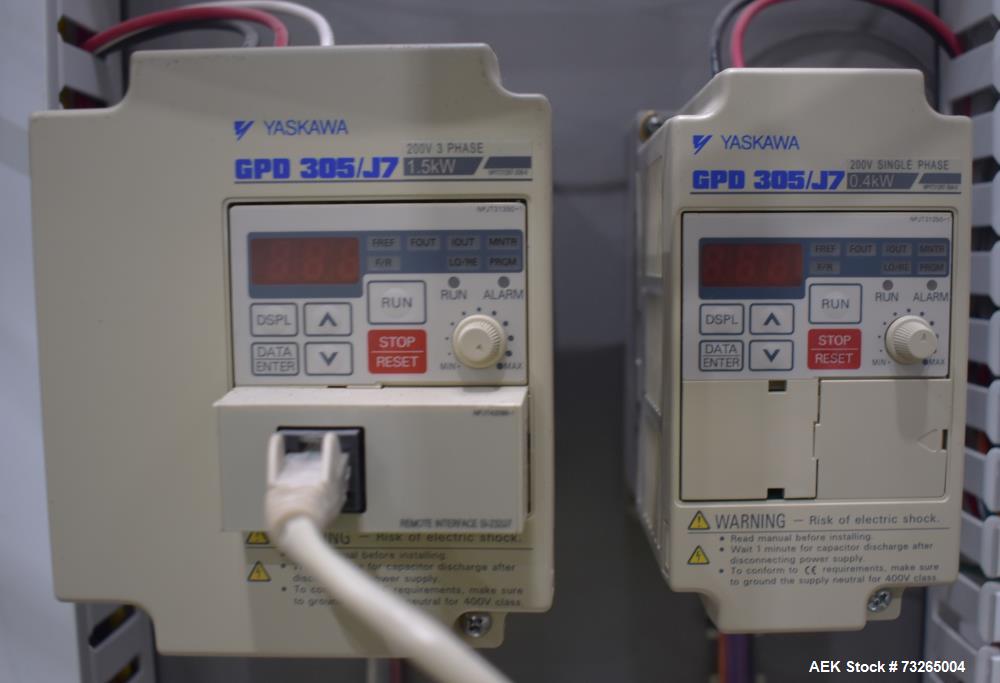

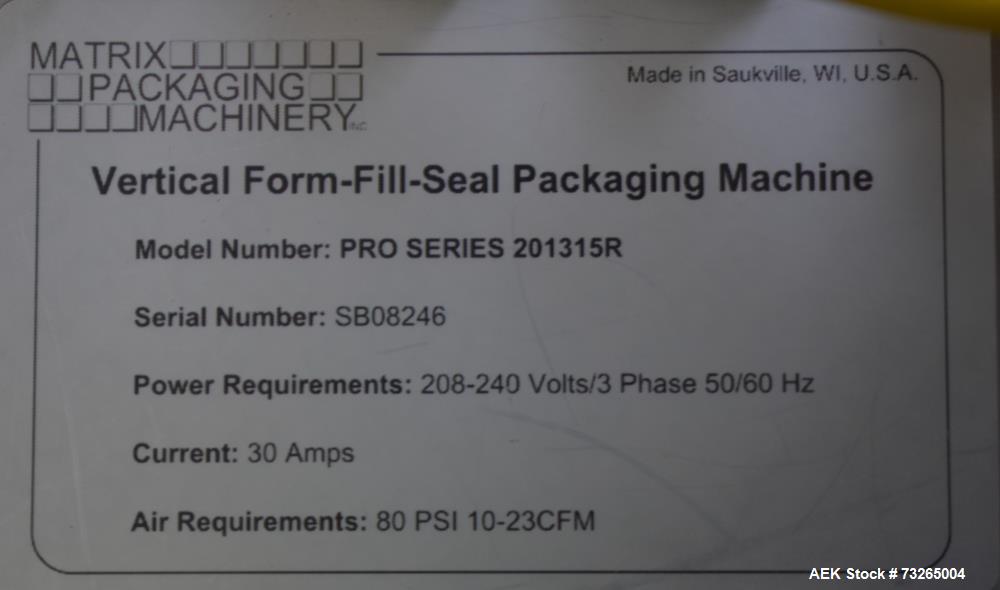

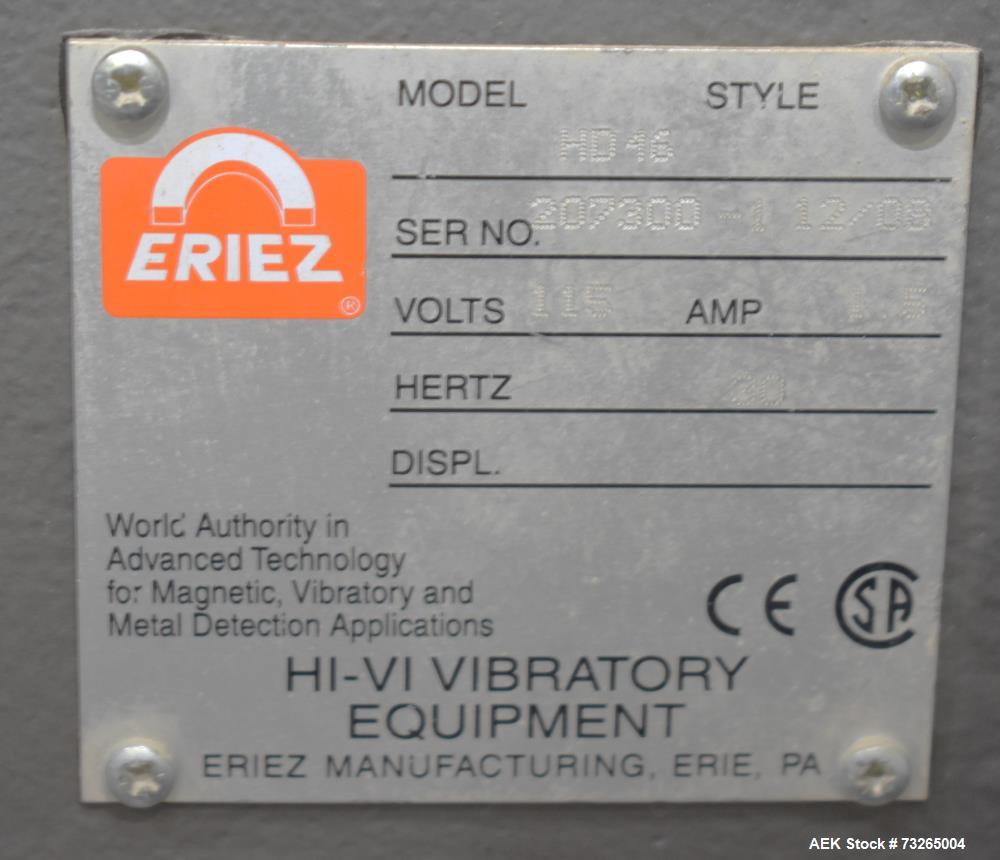

Used Matrix Pro Series Model 20135R Vertical Form Fill Seal Machine. Capable of speeds up to 105 BPM (depending on application). Bag size range: 1.75" - 13" (44mm to 330mm) Wide x 2.5" - 15" (60mm to 390mm) Length (single pull). Has side belt pull downs, film registration and top and bottom gussett. 14" Wide seal jaw. Mitsubishi MELSEC FX2N-32MT PLC, (2) Omron Sysdrive 3G3JV inverter, Parker HMI. Domino V220i. Last running cake mix. 3/60/208-240V, 30 Amp. Air requirements 80 psi, 10-23 CFM. Includes Weigh Right Model PMB403S linear scale, Serial# 20080077.

The Matrix Pro Series Model 20135R is a high-performance vertical form fill seal (VFFS) machine, designed for efficient and precise bagging operations. Capable of operating at speeds of up to 105 bags per minute (BPM) (depending on product and film type), this machine is ideal for high-speed packaging applications across food, pharmaceutical, and industrial sectors.

The system supports a bag size range of:

- Width: 1.75" – 13" (44mm – 330mm)

- Length: 2.5" – 15" (60mm – 390mm) (single pull)

Designed with side belt pull-downs, film registration, and top & bottom gusseting, this unit ensures precise film handling and consistent packaging quality. It features a Mitsubishi MELSEC FX2N-32MT PLC, (2) Omron Sysdrive 3G3JV inverters, and a Parker HMI, providing smooth operation, user-friendly controls, and high-accuracy bagging.

This system was last used for cake mix packaging and includes a Domino V220i coder for batch coding, expiration dates, and traceability.

Additionally, this unit comes equipped with a Weigh Right Model PMB403S linear scale (Serial #20080077), ensuring precise weight measurements for accurate product filling.

The Matrix 20135R operates on 3-phase power (3/60/208-240V, 30 Amp) and requires 80 psi air pressure at 10-23 CFM for efficient performance.

Specifications

- Manufacturer: Matrix Packaging

- Model: Pro Series 20135R

- Machine Type: Vertical Form Fill Seal (VFFS) Machine

- Speed: Up to 105 BPM (bags per minute) (depending on application)

- Bag Size Range:

- Width: 1.75" – 13" (44mm – 330mm)

- Length: 2.5" – 15" (60mm – 390mm) (single pull)

- Film Handling Features:

- Side Belt Pull Downs

- Film Registration

- Top and Bottom Gusseting

- Control System:

- Mitsubishi MELSEC FX2N-32MT PLC

- (2) Omron Sysdrive 3G3JV Inverters

- Parker HMI (Human-Machine Interface)

- Batch Coding System: Domino V220i Coder

- Weighing System: Weigh Right Model PMB403S Linear Scale (Serial #20080077)

- Air Requirements: 80 psi, 10-23 CFM

- Power Requirements: 3/60/208-240V, 30 Amp

- Last Used For: Cake Mix Packaging

Applications

The Matrix Pro Series 20135R VFFS Machine is suitable for a wide range of industries requiring efficient bagging solutions, including:

- Food & Beverage: Cake mix, coffee, spices, grains, snacks, powders, frozen foods.

- Pharmaceuticals & Nutraceuticals: Supplement powders, medical kits, vitamin sachets.

- Personal Care & Cosmetics: Cosmetic powders, bath salts, skincare samples.

- Industrial & Chemical Products: Small hardware, powders, detergents.

This system efficiently forms, fills, and seals bags, offering consistent sealing integrity, reduced downtime, and high-speed performance.

Bakery, Bakery Foods, Bakery Mixes, Cake Mix, cake mixes, Dry Food Products, Flavorings & Spices, flour, Flour Products, Flour, Flour milling,, Food Powder, Pancake Mix, Pancakes, Popcorn, Milling, Bakery, Rice

- Used Matrix Pro Series 20135R VFFS machine

- Matrix vertical form fill seal machine

- Used high-speed bagging machine

- Automatic vertical form fill and seal system

- VFFS machine for food packaging

- Used packaging machine with Domino coder

- Buy used Matrix 20135R vertical form fill seal machine

- Best automatic VFFS machine for cake mix packaging

- High-speed form fill seal system with Mitsubishi PLC

- Matrix VFFS machine with Domino V220i coder

- Affordable industrial bagging machine for powders

- Used VFFS machine with Parker HMI and Omron inverters

- Weigh Right PMB403S scale integrated VFFS machine

Used Matrix Pro Series Model 20135R Vertical Form Fill Seal Machine. Capable of speeds up to 105 BPM (depending on application). Bag size range: 1.75" - 13" (44mm to 330mm) Wide x 2.5" - 15" (60mm to 390mm) Length (single pull). Has side belt pull downs, film registration and top and bottom gussett. 14" Wide seal jaw. Mitsubishi MELSEC FX2N-32MT PLC, (2) Omron Sysdrive 3G3JV inverter, Parker HMI. Domino V220i. Last running cake mix. 3/60/208-240V, 30 Amp. Air requirements 80 psi, 10-23 CFM. Includes Weigh Right Model PMB403S linear scale, Serial# 20080077.

The Matrix Pro Series Model 20135R is a high-performance vertical form fill seal (VFFS) machine, designed for efficient and precise bagging operations. Capable of operating at speeds of up to 105 bags per minute (BPM) (depending on product and film type), this machine is ideal for high-speed packaging applications across food, pharmaceutical, and industrial sectors.

The system supports a bag size range of:

- Width: 1.75" – 13" (44mm – 330mm)

- Length: 2.5" – 15" (60mm – 390mm) (single pull)

Designed with side belt pull-downs, film registration, and top & bottom gusseting, this unit ensures precise film handling and consistent packaging quality. It features a Mitsubishi MELSEC FX2N-32MT PLC, (2) Omron Sysdrive 3G3JV inverters, and a Parker HMI, providing smooth operation, user-friendly controls, and high-accuracy bagging.

This system was last used for cake mix packaging and includes a Domino V220i coder for batch coding, expiration dates, and traceability.

Additionally, this unit comes equipped with a Weigh Right Model PMB403S linear scale (Serial #20080077), ensuring precise weight measurements for accurate product filling.

The Matrix 20135R operates on 3-phase power (3/60/208-240V, 30 Amp) and requires 80 psi air pressure at 10-23 CFM for efficient performance.

Specifications

- Manufacturer: Matrix Packaging

- Model: Pro Series 20135R

- Machine Type: Vertical Form Fill Seal (VFFS) Machine

- Speed: Up to 105 BPM (bags per minute) (depending on application)

- Bag Size Range:

- Width: 1.75" – 13" (44mm – 330mm)

- Length: 2.5" – 15" (60mm – 390mm) (single pull)

- Film Handling Features:

- Side Belt Pull Downs

- Film Registration

- Top and Bottom Gusseting

- Control System:

- Mitsubishi MELSEC FX2N-32MT PLC

- (2) Omron Sysdrive 3G3JV Inverters

- Parker HMI (Human-Machine Interface)

- Batch Coding System: Domino V220i Coder

- Weighing System: Weigh Right Model PMB403S Linear Scale (Serial #20080077)

- Air Requirements: 80 psi, 10-23 CFM

- Power Requirements: 3/60/208-240V, 30 Amp

- Last Used For: Cake Mix Packaging

Applications

The Matrix Pro Series 20135R VFFS Machine is suitable for a wide range of industries requiring efficient bagging solutions, including:

- Food & Beverage: Cake mix, coffee, spices, grains, snacks, powders, frozen foods.

- Pharmaceuticals & Nutraceuticals: Supplement powders, medical kits, vitamin sachets.

- Personal Care & Cosmetics: Cosmetic powders, bath salts, skincare samples.

- Industrial & Chemical Products: Small hardware, powders, detergents.

This system efficiently forms, fills, and seals bags, offering consistent sealing integrity, reduced downtime, and high-speed performance.

Bakery, Bakery Foods, Bakery Mixes, Cake Mix, cake mixes, Dry Food Products, Flavorings & Spices, flour, Flour Products, Flour, Flour milling,, Food Powder, Pancake Mix, Pancakes, Popcorn, Milling, Bakery, Rice

- Used Matrix Pro Series 20135R VFFS machine

- Matrix vertical form fill seal machine

- Used high-speed bagging machine

- Automatic vertical form fill and seal system

- VFFS machine for food packaging

- Used packaging machine with Domino coder

- Buy used Matrix 20135R vertical form fill seal machine

- Best automatic VFFS machine for cake mix packaging

- High-speed form fill seal system with Mitsubishi PLC

- Matrix VFFS machine with Domino V220i coder

- Affordable industrial bagging machine for powders

- Used VFFS machine with Parker HMI and Omron inverters

- Weigh Right PMB403S scale integrated VFFS machine

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory