Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Used All Fill Model B-SV-600 Semi Automatic Auger Filler

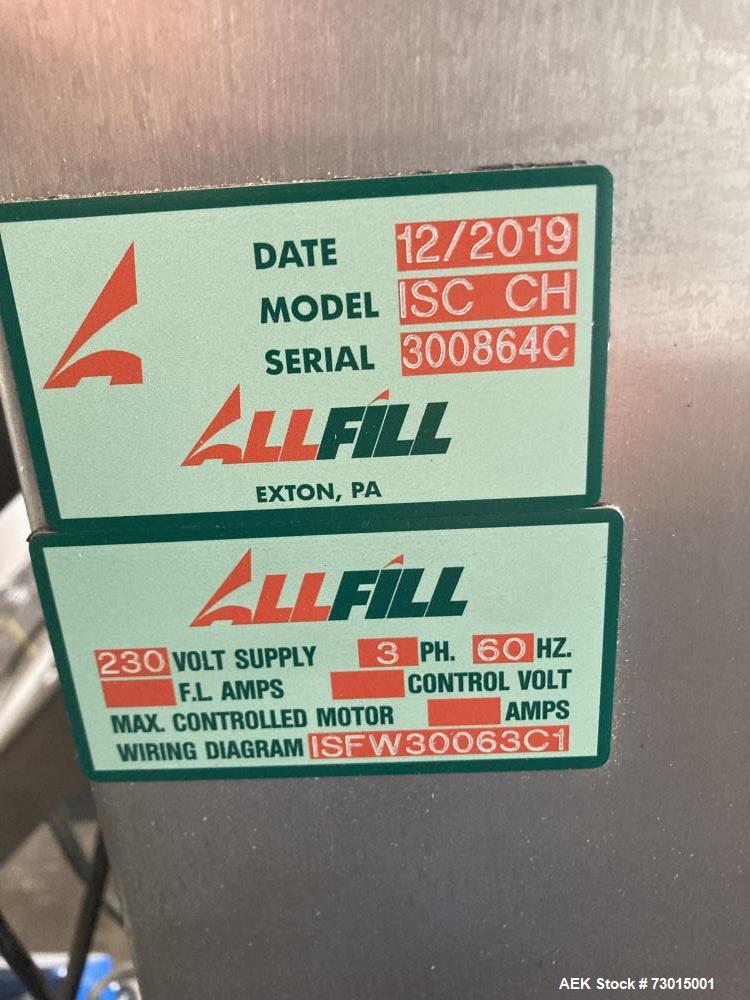

Used All Fill Model B-SV-600 Semi Automatic Auger Filler with Screw Feeder. Filler Specifications- Filling machine used for dry spices Tooling for Free Flowing products Construction - Stainless steel product contact parts. Standard cast aluminum bench/floor base,. One-piece stainless steel head cover and stainless steel contact parts. 3-speed fill motor drive system. Rugged head casting and stable cast base. Electrical requirements- Input: 208/230/460V; 3-Phase; 60HZ. Standard Controls: 115V 50-60 HZ Controls- Embedded controller, 7.00" color touch screen HMI, foot pedal initiation, A self-aligning, quick-disconnect coupling on the hopper allows for fast removal and replacement for cleaning or product changeover, Individual control of all settings, Alphanumeric product naming, Containers per minute readout, Automatic tare and statistical analysis of a shift run , Users/Maintenance /Supervisor login, Clutch Brake: Standard 3-step belt drive with a 1-1/2 HP, 1200 RPM fill motor, An integral electro-magnetic clutch brake controls shaft movement Capacity-Hopper- 10 or 16 gallons provides ample capacity and sufficient head pressure for repeatable, accurate filling Machine Dimensions-45" x 82" Changeover-Mostly tool-less AFI Model 10Ft Screwfeeder DH-S2 series Vibrating Hopper Inclined Screw Conveyor Used for dry spices.Construction- Stainless Steel Frame Welded and polished type-304 stainless steel product contact parts, Mounting frame with adjustable feet and removable hopper cover Size- 5.5" dia. X 10 long ground and polished stainless steel screw with matching, pivoting housing, Adjustable discharge height, standard 74" Machine dimensions- 113" wide X 92" high Electrical Requirements- 208/230/460v, 3-phase, 60 HZ. Features- 1/4 hp, 1400 rpm drive and controls, 6 cu. ft. hopper with hinged cover, Safety limit switches on hopper covers, Delivery speeds up to 150 cu. ft per hour, Variable length (10'12'), 5" inch pitch, 5.5 " diameter

Used All Fill Model B-SV-600 Semi Automatic Auger Filler with Screw Feeder. Filler Specifications- Filling machine used for dry spices Tooling for Free Flowing products Construction - Stainless steel product contact parts. Standard cast aluminum bench/floor base,. One-piece stainless steel head cover and stainless steel contact parts. 3-speed fill motor drive system. Rugged head casting and stable cast base. Electrical requirements- Input: 208/230/460V; 3-Phase; 60HZ. Standard Controls: 115V 50-60 HZ Controls- Embedded controller, 7.00" color touch screen HMI, foot pedal initiation, A self-aligning, quick-disconnect coupling on the hopper allows for fast removal and replacement for cleaning or product changeover, Individual control of all settings, Alphanumeric product naming, Containers per minute readout, Automatic tare and statistical analysis of a shift run , Users/Maintenance /Supervisor login, Clutch Brake: Standard 3-step belt drive with a 1-1/2 HP, 1200 RPM fill motor, An integral electro-magnetic clutch brake controls shaft movement Capacity-Hopper- 10 or 16 gallons provides ample capacity and sufficient head pressure for repeatable, accurate filling Machine Dimensions-45" x 82" Changeover-Mostly tool-less AFI Model 10Ft Screwfeeder DH-S2 series Vibrating Hopper Inclined Screw Conveyor Used for dry spices.Construction- Stainless Steel Frame Welded and polished type-304 stainless steel product contact parts, Mounting frame with adjustable feet and removable hopper cover Size- 5.5" dia. X 10 long ground and polished stainless steel screw with matching, pivoting housing, Adjustable discharge height, standard 74" Machine dimensions- 113" wide X 92" high Electrical Requirements- 208/230/460v, 3-phase, 60 HZ. Features- 1/4 hp, 1400 rpm drive and controls, 6 cu. ft. hopper with hinged cover, Safety limit switches on hopper covers, Delivery speeds up to 150 cu. ft per hour, Variable length (10'12'), 5" inch pitch, 5.5 " diameter

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory

.jpg)