Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Used Pattyn Automated Packaging System – High-Speed Case Erecting and Bag Inserting Solution

Used Pattyn Automated Packaging System. 300 parts per minute and has a capacity of 440 parts per box. System consists of: Combination Case Erector and Bag Inserter MTM12; Driven Roll Conveyor; Driven Roll Conveyor; Bag Decuffer Folder (American); 31 Case Closer Tape; Driven Roll Conveyor; Case conveyors (instead of Box flow); Robotic palletizer; Pallet conveyor; Perimeter safety fencing; 750mm zone x 2; Decline belt conveyors; Pop-up Transfer; Lower conveyor: 30 meters of conveyor (20 zones of 1500mm), 24 meters of conveyor (16 zones of 1500mm); Overhead conveyor: 30 meters of conveyor (20 zones of 1500mm), 22.5 meters of conveyor (15 zones of 1500mm), Extended legs; Pop-up Transfer; 750mm zone x 1, 1050mm zone x 1 (650mm width); Pop-up Transfer; 1500mm zone x 2; Decline belt conveyor; 750mm zone + 90 curve + 525mm zone + 90 curve + 1050mm zone; Power supplies + electrical controls; TIJPrinter (6) + side-mount stand; Barcode scanner; ID Tech Labeling machine Model 252 + stand. New in 2022.

| Manufacturer | PattynPattyn |

| Category | Packaging EquipmentPackaging Equipment |

| Subcategory | Complete Packaging Line - Bulk BagComplete Packaging Line - Bulk Bag |

Manufacturer’s Info:

-

Manufacturer: Pattyn Packaging Lines

-

Model: MTM12

-

Year Built: 2022

Description: The Pattyn Automated Packaging System is designed for high-speed, efficient packaging operations, capable of handling up to 300 parts per minute with a capacity of 440 parts per box. This comprehensive system integrates multiple components to streamline the packaging process, ensuring precision and reliability.

System Components:

-

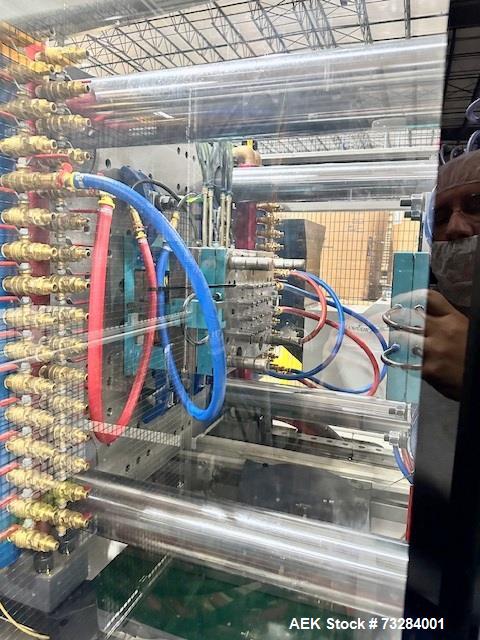

Combination Case Erector and Bag Inserter (Model MTM12): Automates the formation of cases and insertion of bags, enhancing efficiency.

-

Driven Roll Conveyors: Facilitate smooth and consistent movement of cases through the packaging line.

-

Bag Decuffer Folder (American): Ensures proper bag positioning and sealing within cases.

-

Case Closer (Model 31 Case Closer Tape): Secures cases with tape, maintaining package integrity.

-

Robotic Palletizer: Automates the stacking of cases onto pallets, reducing manual labor and increasing safety.

-

Pallet Conveyor: Transports loaded pallets efficiently within the facility.

-

Perimeter Safety Fencing: Provides a secure environment by enclosing the operational area.

-

Decline Belt Conveyors and Pop-up Transfers: Manage product flow and orientation throughout the system.

-

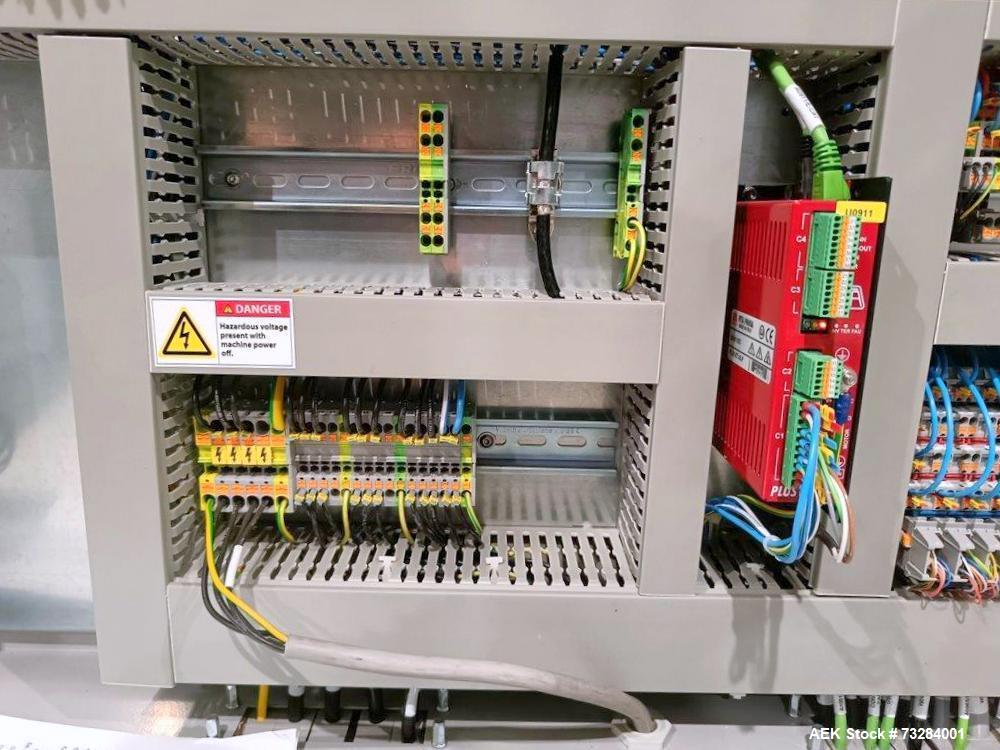

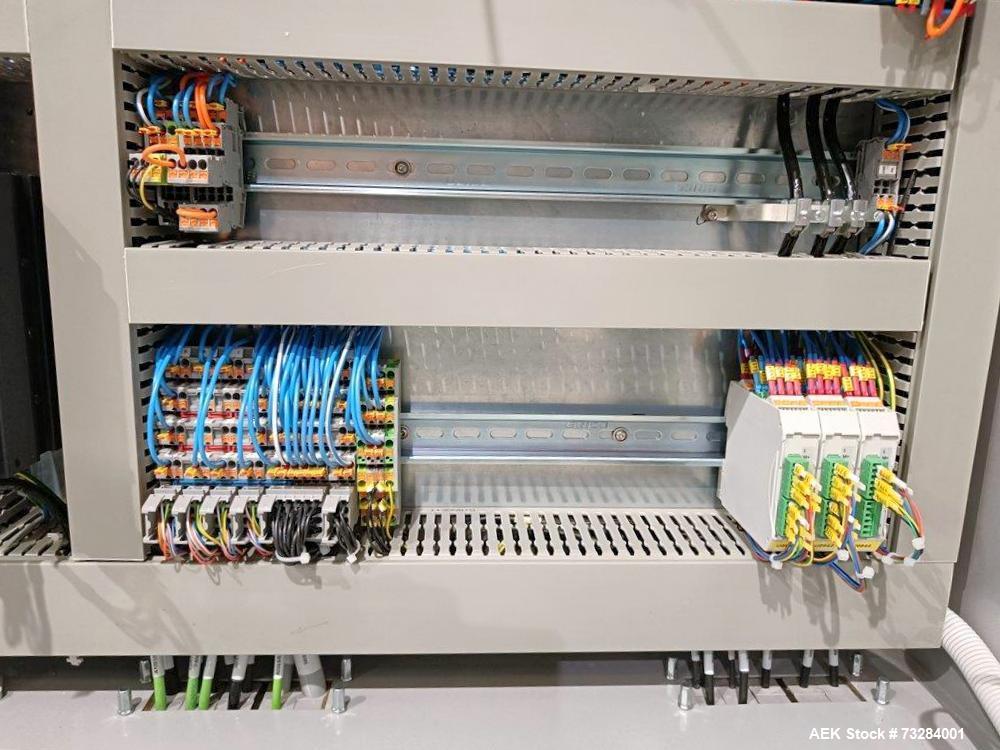

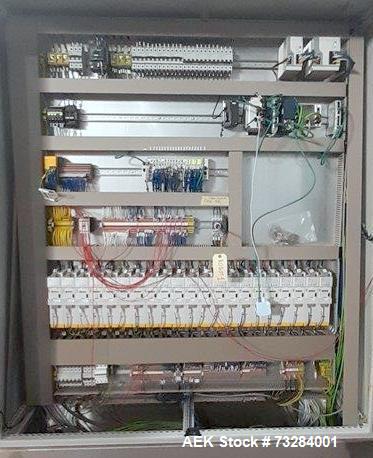

Power Supplies and Electrical Controls: Ensure consistent and reliable operation of all components.

-

TIJ Printers (6) with Side-Mount Stands: Enable on-the-fly printing of labels or barcodes on packages.

-

Barcode Scanner: Facilitates tracking and quality control by scanning package barcodes.

-

ID Tech Labeling Machine (Model 252) with Stand: Applies labels accurately to packages, enhancing product identification.

Specifications:

-

Speed: Up to 300 parts per minute

-

Box Capacity: 440 parts per box

-

Conveyor Details:

-

Lower Conveyor: 30 meters (20 zones of 1500mm), 24 meters (16 zones of 1500mm)

-

Overhead Conveyor: 30 meters (20 zones of 1500mm), 22.5 meters (15 zones of 1500mm) with extended legs

-

Pop-up Transfers: Various zones including 750mm, 1050mm (650mm width), and 1500mm zones

-

Decline Belt Conveyor: 750mm zone with 90-degree curves and additional zones

-

Applications: This automated packaging system is ideal for industries requiring high-speed, precise packaging solutions, including:

-

Food and Beverage: Efficiently packages food products into cases with protective bag inserts.

-

Pharmaceuticals: Ensures secure and contamination-free packaging of medical products.

-

Consumer Goods: Handles a variety of products, enhancing packaging efficiency and consistency.

What Products Would This Be Used For?

-

Bakery Items: Bread, pastries, and other baked goods requiring protective packaging.

-

Frozen Foods: Products needing secure packaging to maintain quality during storage and transport.

-

Industrial Components: Small parts or components packaged in bulk for distribution.

Consumer Goods, Consumer Products, Manufacturer, Manufacturing, Manufacturing Industry, Packaging, Packaging Equipment

-

Used Pattyn Automated Packaging System?

-

Pattyn MTM12 Case Erector and Bag Inserter?

-

High-Speed Packaging System 300 parts per minute?

-

Automated Case Packing Equipment

-

Pattyn Packaging Line for Sale?

Used Pattyn Automated Packaging System. 300 parts per minute and has a capacity of 440 parts per box. System consists of: Combination Case Erector and Bag Inserter MTM12; Driven Roll Conveyor; Driven Roll Conveyor; Bag Decuffer Folder (American); 31 Case Closer Tape; Driven Roll Conveyor; Case conveyors (instead of Box flow); Robotic palletizer; Pallet conveyor; Perimeter safety fencing; 750mm zone x 2; Decline belt conveyors; Pop-up Transfer; Lower conveyor: 30 meters of conveyor (20 zones of 1500mm), 24 meters of conveyor (16 zones of 1500mm); Overhead conveyor: 30 meters of conveyor (20 zones of 1500mm), 22.5 meters of conveyor (15 zones of 1500mm), Extended legs; Pop-up Transfer; 750mm zone x 1, 1050mm zone x 1 (650mm width); Pop-up Transfer; 1500mm zone x 2; Decline belt conveyor; 750mm zone + 90 curve + 525mm zone + 90 curve + 1050mm zone; Power supplies + electrical controls; TIJPrinter (6) + side-mount stand; Barcode scanner; ID Tech Labeling machine Model 252 + stand. New in 2022.

Manufacturer’s Info:

-

Manufacturer: Pattyn Packaging Lines

-

Model: MTM12

-

Year Built: 2022

Description: The Pattyn Automated Packaging System is designed for high-speed, efficient packaging operations, capable of handling up to 300 parts per minute with a capacity of 440 parts per box. This comprehensive system integrates multiple components to streamline the packaging process, ensuring precision and reliability.

System Components:

-

Combination Case Erector and Bag Inserter (Model MTM12): Automates the formation of cases and insertion of bags, enhancing efficiency.

-

Driven Roll Conveyors: Facilitate smooth and consistent movement of cases through the packaging line.

-

Bag Decuffer Folder (American): Ensures proper bag positioning and sealing within cases.

-

Case Closer (Model 31 Case Closer Tape): Secures cases with tape, maintaining package integrity.

-

Robotic Palletizer: Automates the stacking of cases onto pallets, reducing manual labor and increasing safety.

-

Pallet Conveyor: Transports loaded pallets efficiently within the facility.

-

Perimeter Safety Fencing: Provides a secure environment by enclosing the operational area.

-

Decline Belt Conveyors and Pop-up Transfers: Manage product flow and orientation throughout the system.

-

Power Supplies and Electrical Controls: Ensure consistent and reliable operation of all components.

-

TIJ Printers (6) with Side-Mount Stands: Enable on-the-fly printing of labels or barcodes on packages.

-

Barcode Scanner: Facilitates tracking and quality control by scanning package barcodes.

-

ID Tech Labeling Machine (Model 252) with Stand: Applies labels accurately to packages, enhancing product identification.

Specifications:

-

Speed: Up to 300 parts per minute

-

Box Capacity: 440 parts per box

-

Conveyor Details:

-

Lower Conveyor: 30 meters (20 zones of 1500mm), 24 meters (16 zones of 1500mm)

-

Overhead Conveyor: 30 meters (20 zones of 1500mm), 22.5 meters (15 zones of 1500mm) with extended legs

-

Pop-up Transfers: Various zones including 750mm, 1050mm (650mm width), and 1500mm zones

-

Decline Belt Conveyor: 750mm zone with 90-degree curves and additional zones

-

Applications: This automated packaging system is ideal for industries requiring high-speed, precise packaging solutions, including:

-

Food and Beverage: Efficiently packages food products into cases with protective bag inserts.

-

Pharmaceuticals: Ensures secure and contamination-free packaging of medical products.

-

Consumer Goods: Handles a variety of products, enhancing packaging efficiency and consistency.

What Products Would This Be Used For?

-

Bakery Items: Bread, pastries, and other baked goods requiring protective packaging.

-

Frozen Foods: Products needing secure packaging to maintain quality during storage and transport.

-

Industrial Components: Small parts or components packaged in bulk for distribution.

Consumer Goods, Consumer Products, Manufacturer, Manufacturing, Manufacturing Industry, Packaging, Packaging Equipment

| Manufacturer | Pattyn |

| Category | Packaging Equipment |

| Subcategory | Complete Packaging Line - Bulk Bag |

-

Used Pattyn Automated Packaging System?

-

Pattyn MTM12 Case Erector and Bag Inserter?

-

High-Speed Packaging System 300 parts per minute?

-

Automated Case Packing Equipment

-

Pattyn Packaging Line for Sale?

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory