Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

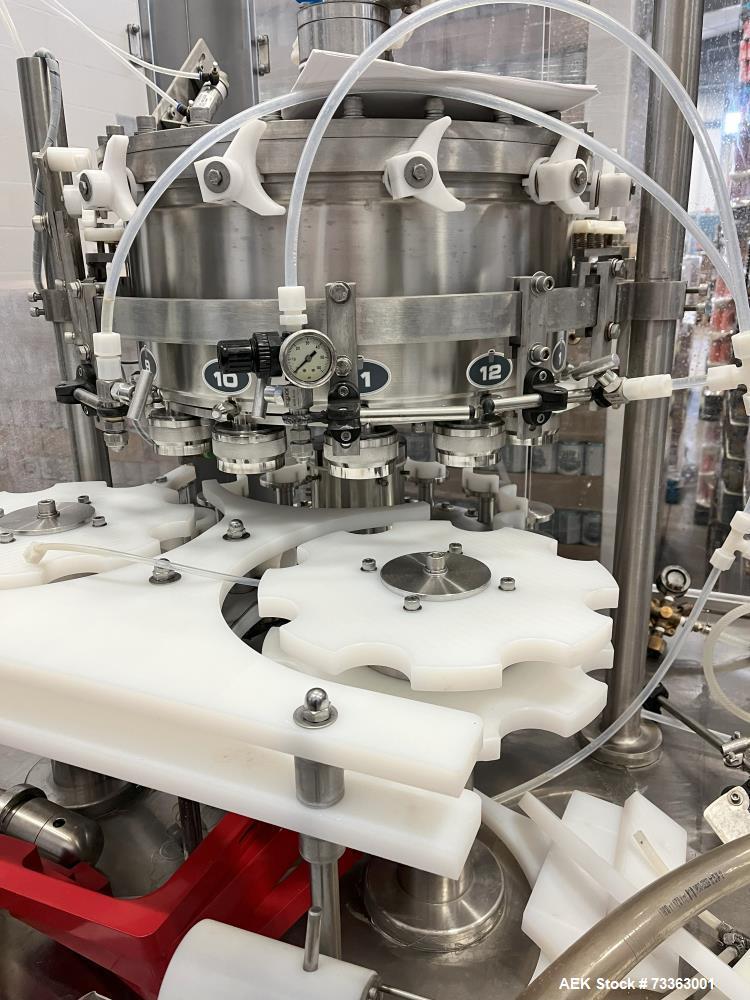

Used Palmer Canning CraftBloc 12/1 Can Filler & Seamer – 12 Valve, 28-50 CPM

Used Palmer Canning Systems Craftbloc 12/1 Can Filler and Seamer. 12 valve counter pressure filler; 28-50 cans per minute; Allen Bradley PLC control for entire system and synchronization of filler, seamer, and can conveyance; Heavy duty seams preserve high CO2 retention; Seaming tooling, titanium carbide and nitride coated rolls and chucks with ceramic bearings; Mechanical cam-driven seaming, heavy-duty, Continental 450; Undercover gas manifold. Fills standard, sleek, and slim cans; filling accuracy 5 grams (5 ml); Max CO2 volume 3.5 V/V (Beer 2.0-3.0); 3/60/230 volt; CO2 consumption 6-10 CFM at 60 psi.

| Manufacturer | PalmerPalmer |

| Model | 12/1 |

| Category | Packaging EquipmentPackaging Equipment |

| Subcategory | Beverage Equipment - Carbonated MonoblockBeverage Equipment - Carbonated Monoblock |

-

Food and Beverage:

- Fruits and Vegetables: Canning fruits, vegetables, juices, and other food products.

- Meat and Seafood: Canning meat, poultry, fish, and seafood products.

- Soups and Sauces: Canning soups, sauces, stews, and other prepared foods.

- Beverages: Canning carbonated and non-carbonated beverages, including soft drinks, juices, and energy drinks.

- Fruits and Vegetables: Canning fruits, vegetables, juices, and other food products.

-

Other Industries:

- Pet Food: Canning wet pet food.

- Pharmaceuticals: Canning certain pharmaceutical products.

- Industrial Applications: Canning lubricants, chemicals, and other industrial products.

- Pet Food: Canning wet pet food.

Key Functions of Can Filler and Seamers:

- Filling: Accurately fills cans with the desired product, ensuring consistent fill levels.

- Seaming: Seals the can lids securely to the can bodies, creating an airtight and tamper-resistant package.

By using these machines, manufacturers can efficiently and reliably produce high-quality canned products with extended shelf life.

Beer, beer, brewery, Beverage, Brewery, Brewery, Beer, Can canning, Can Filling, canned food, Canned Goods, canning, Cans, Coffee, Cold Brew Coffee, Craft Breweries, Craft Brewing, Food and Beverage, Food Packaging, Food Plants, Food Products, Fruit, Fruit & Fruit Juice, Fruit Concentrates, Fruit Fillings, fruit juice, Fruit Puree, Fruits, Liquids, Meat Packing, Meats, Pet Food, Pet Food,, Pet Products, pharma, Pharmaceutical, Pharmaceutical Products, Pharmaceuticals, Sauce, Sauces, Soup, Soup Base, Soup Can, Soup Mixes, Soup Pastes, Soups, Tea, Teas

- Used Palmer Canning Systems CraftBloc 12/1 can filler and seamer

- High-speed 12-valve counter pressure filler for beverage canning

- Automated beer canning system with Allen Bradley PLC controls

- Heavy-duty Continental 450 mechanical cam-driven seamer

- Titanium carbide and nitride-coated seaming tooling for durability

- CO2 retention canning system for soft drinks, beer, and hard seltzers

- Craft beer canning machine with undercover gas manifold

- Palmer CraftBloc canning line for standard, sleek, and slim cans

- Precision beverage filling system with ±5g accuracy

- Industrial canning machine for carbonated and non-carbonated drinks

- Used Palmer Canning Systems CraftBloc 12/1 can filler and seamer for sale

- High-speed counter pressure can filling and seaming system for craft brewing

- Precision beer canning machine with CO2 retention and seaming durability

- Used beverage canning equipment for soda, energy drinks, and hard seltzers

- Automated Palmer CraftBloc filling system with 28-50 CPM capacity

- Pre-owned industrial can filling and seaming machine for breweries

- Allen Bradley PLC-controlled beverage filling and sealing system

- Heavy-duty titanium carbide-coated seaming system for carbonated beverages

- Craft beer filling and seaming machine with mechanical cam-driven seamer

- Palmer Canning CraftBloc system for standard, sleek, and slim cans

Used Palmer Canning Systems Craftbloc 12/1 Can Filler and Seamer. 12 valve counter pressure filler; 28-50 cans per minute; Allen Bradley PLC control for entire system and synchronization of filler, seamer, and can conveyance; Heavy duty seams preserve high CO2 retention; Seaming tooling, titanium carbide and nitride coated rolls and chucks with ceramic bearings; Mechanical cam-driven seaming, heavy-duty, Continental 450; Undercover gas manifold. Fills standard, sleek, and slim cans; filling accuracy 5 grams (5 ml); Max CO2 volume 3.5 V/V (Beer 2.0-3.0); 3/60/230 volt; CO2 consumption 6-10 CFM at 60 psi.

-

Food and Beverage:

- Fruits and Vegetables: Canning fruits, vegetables, juices, and other food products.

- Meat and Seafood: Canning meat, poultry, fish, and seafood products.

- Soups and Sauces: Canning soups, sauces, stews, and other prepared foods.

- Beverages: Canning carbonated and non-carbonated beverages, including soft drinks, juices, and energy drinks.

- Fruits and Vegetables: Canning fruits, vegetables, juices, and other food products.

-

Other Industries:

- Pet Food: Canning wet pet food.

- Pharmaceuticals: Canning certain pharmaceutical products.

- Industrial Applications: Canning lubricants, chemicals, and other industrial products.

- Pet Food: Canning wet pet food.

Key Functions of Can Filler and Seamers:

- Filling: Accurately fills cans with the desired product, ensuring consistent fill levels.

- Seaming: Seals the can lids securely to the can bodies, creating an airtight and tamper-resistant package.

By using these machines, manufacturers can efficiently and reliably produce high-quality canned products with extended shelf life.

Beer, beer, brewery, Beverage, Brewery, Brewery, Beer, Can canning, Can Filling, canned food, Canned Goods, canning, Cans, Coffee, Cold Brew Coffee, Craft Breweries, Craft Brewing, Food and Beverage, Food Packaging, Food Plants, Food Products, Fruit, Fruit & Fruit Juice, Fruit Concentrates, Fruit Fillings, fruit juice, Fruit Puree, Fruits, Liquids, Meat Packing, Meats, Pet Food, Pet Food,, Pet Products, pharma, Pharmaceutical, Pharmaceutical Products, Pharmaceuticals, Sauce, Sauces, Soup, Soup Base, Soup Can, Soup Mixes, Soup Pastes, Soups, Tea, Teas

| Manufacturer | Palmer |

| Model | 12/1 |

| Category | Packaging Equipment |

| Subcategory | Beverage Equipment - Carbonated Monoblock |

- Used Palmer Canning Systems CraftBloc 12/1 can filler and seamer

- High-speed 12-valve counter pressure filler for beverage canning

- Automated beer canning system with Allen Bradley PLC controls

- Heavy-duty Continental 450 mechanical cam-driven seamer

- Titanium carbide and nitride-coated seaming tooling for durability

- CO2 retention canning system for soft drinks, beer, and hard seltzers

- Craft beer canning machine with undercover gas manifold

- Palmer CraftBloc canning line for standard, sleek, and slim cans

- Precision beverage filling system with ±5g accuracy

- Industrial canning machine for carbonated and non-carbonated drinks

- Used Palmer Canning Systems CraftBloc 12/1 can filler and seamer for sale

- High-speed counter pressure can filling and seaming system for craft brewing

- Precision beer canning machine with CO2 retention and seaming durability

- Used beverage canning equipment for soda, energy drinks, and hard seltzers

- Automated Palmer CraftBloc filling system with 28-50 CPM capacity

- Pre-owned industrial can filling and seaming machine for breweries

- Allen Bradley PLC-controlled beverage filling and sealing system

- Heavy-duty titanium carbide-coated seaming system for carbonated beverages

- Craft beer filling and seaming machine with mechanical cam-driven seamer

- Palmer Canning CraftBloc system for standard, sleek, and slim cans

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory