Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Matcon IBC Blending System.

Unused- Matcon IBC Blending System. Capable of capacities 2700L-3300L; 60 minute blender limitation time;System comprising: operator safety fence; Manual IBC fill unit, cone clamp station, control panel; (5) 2700L S13 stainless steel IBC w/ NIR mounting; IBC discharge system comprised of discharge station, discharge station load cells, weigh amplifier, and control system. Blender controlled by AB Micrologix PLC and Compact 600 HMI. 4-16 RPM blender rotating speed; 11kW (approximate 14.75 HP) electric motor drive; 3/60/460V. Built 2021.

Manufacturer Information

- Manufacturer: Matcon

- Model: IBC Blending System

- Condition: Unused / Like New

- Year of Manufacture: 2021

- Availability: Immediate

Description

Unused - In Stock! This Matcon IBC Blending System is a state-of-the-art powder blending solution designed for high-capacity, efficient, and contamination-free mixing. With a capacity range of 2700L to 3300L, it is ideal for pharmaceutical, nutraceutical, food, and chemical industries requiring precision blending and scalable batch processing.

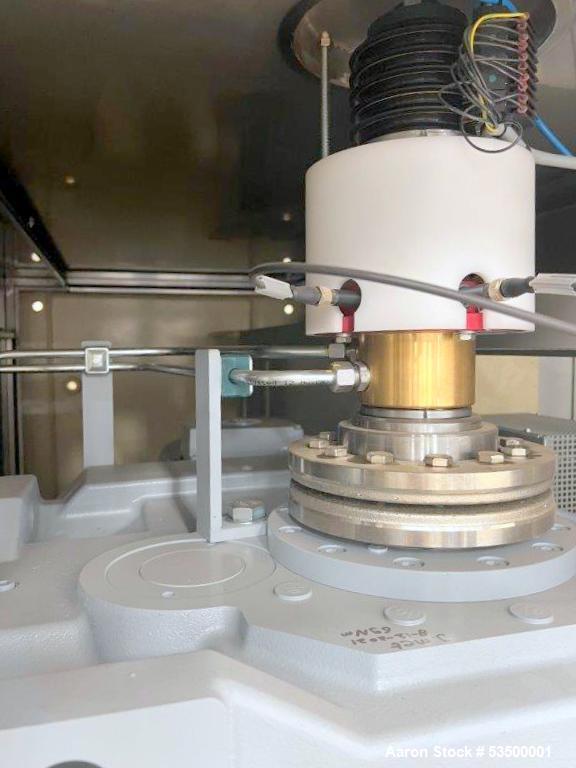

This comprehensive blending system includes a single plinth blender with an intensifier, allowing enhanced mixing capabilities through high-speed intensification at up to 3000 RPM. The intensifier lid and handling trolley facilitate secure and efficient transfer. Operator safety is ensured with a safety fence surrounding the system.

The system comes complete with a manual IBC fill unit, cone clamp station, and control panel for smooth operation. The IBC discharge system includes a discharge station with load cells, weigh amplifier, and control system, providing precision weighing and discharge control.

The blender is powered by an 11kW (approx. 14.75 HP) electric motor drive, offering a blender rotation speed of 4-16 RPM. It is controlled by an Allen-Bradley Micrologix PLC and Compact 600 HMI, ensuring precise and user-friendly control of the entire process. The system is rated for 3-phase, 60 Hz, 460V power supply.

Included in the system are (5) 2700L S13 stainless steel IBCs equipped with NIR mounting, making it a turnkey solution for large-scale powder blending operations.

Specifications

- Manufacturer: Matcon

- Model: IBC Blending System

- Condition: Unused / In Stock

- Year Built: 2021

- Capacity Range: 2700L - 3300L

- Blender Type: Single Plinth Blender with Intensifier

- Blender Limitation Time: 60 Minutes

- Blender Rotating Speed: 4-16 RPM

- Intensifier Speed: Up to 3000 RPM

- Electric Motor: 11kW (Approx. 14.75 HP)

- Voltage: 3/60/460V

- Control System: Allen-Bradley Micrologix PLC with Compact 600 HMI

- Included Components:

- Single Plinth Blender

- Intensifier Lid

- Intensifier Handling Trolley

- Operator Safety Fence

- Manual IBC Fill Unit

- Cone Clamp Station

- Control Panel

- IBC Discharge System with Discharge Station, Load Cells, Weigh Amplifier, Control System

- IBC Tanks: (5) 2700L S13 Stainless Steel IBCs with NIR Mounting

Applications

- Pharmaceutical powder blending

- Nutraceutical ingredient mixing

- Food industry powder blending

- Dry chemical blending

- Dairy powder mixing

- Specialty powders and granules blending

- Nutrient and supplement production

- High-value product containment and processing

- Contamination-sensitive mixing applications

- Scalable batch powder manufacturing

Products This System Can Be Used For

- Pharmaceutical tablets and powders

- Nutraceutical and dietary supplement blends

- Protein powders and meal replacements

- Food ingredients (spices, cocoa, flour blends)

- Chemical powders and resins

- Dairy powders and infant formula

- Cosmetic powders

- Plastic granules and additives

- Agricultural powders and seeds

- Specialty custom powder formulations

Blending, Granular Materials, Granular products, Granulating, Granules, Powder Production, Powders

- Matcon IBC blending system

- 2700L stainless steel IBC blender

- Unused Matcon blender for sale

- Industrial powder blending system

- IBC blender with intensifier

- High capacity powder mixing system

- Matcon blending equipment 2021

- Allen-Bradley controlled blender

- Food-grade IBC blending system

- Pharmaceutical powder mixer

- IBC blender

- Industrial blending system

- Powder blending equipment

- Stainless steel blender

- Matcon powder blender

- Pharmaceutical mixer

- Nutraceutical blending equipment

- Food-grade IBC mixer

- Unused powder blending system

- Industrial intensifier blender

- Buy Matcon IBC blending system

- Unused powder blender for sale

- 2700L stainless steel IBC blender available

- Industrial blending system dealer

- Sell high-capacity powder blenders

- Matcon blender with intensifier for sale

- Pharmaceutical and nutraceutical blender

- IBC blending equipment supplier

- 2021 Matcon blender in stock

Unused- Matcon IBC Blending System. Capable of capacities 2700L-3300L; 60 minute blender limitation time;System comprising: operator safety fence; Manual IBC fill unit, cone clamp station, control panel; (5) 2700L S13 stainless steel IBC w/ NIR mounting; IBC discharge system comprised of discharge station, discharge station load cells, weigh amplifier, and control system. Blender controlled by AB Micrologix PLC and Compact 600 HMI. 4-16 RPM blender rotating speed; 11kW (approximate 14.75 HP) electric motor drive; 3/60/460V. Built 2021.

Manufacturer Information

- Manufacturer: Matcon

- Model: IBC Blending System

- Condition: Unused / Like New

- Year of Manufacture: 2021

- Availability: Immediate

Description

Unused - In Stock! This Matcon IBC Blending System is a state-of-the-art powder blending solution designed for high-capacity, efficient, and contamination-free mixing. With a capacity range of 2700L to 3300L, it is ideal for pharmaceutical, nutraceutical, food, and chemical industries requiring precision blending and scalable batch processing.

This comprehensive blending system includes a single plinth blender with an intensifier, allowing enhanced mixing capabilities through high-speed intensification at up to 3000 RPM. The intensifier lid and handling trolley facilitate secure and efficient transfer. Operator safety is ensured with a safety fence surrounding the system.

The system comes complete with a manual IBC fill unit, cone clamp station, and control panel for smooth operation. The IBC discharge system includes a discharge station with load cells, weigh amplifier, and control system, providing precision weighing and discharge control.

The blender is powered by an 11kW (approx. 14.75 HP) electric motor drive, offering a blender rotation speed of 4-16 RPM. It is controlled by an Allen-Bradley Micrologix PLC and Compact 600 HMI, ensuring precise and user-friendly control of the entire process. The system is rated for 3-phase, 60 Hz, 460V power supply.

Included in the system are (5) 2700L S13 stainless steel IBCs equipped with NIR mounting, making it a turnkey solution for large-scale powder blending operations.

Specifications

- Manufacturer: Matcon

- Model: IBC Blending System

- Condition: Unused / In Stock

- Year Built: 2021

- Capacity Range: 2700L - 3300L

- Blender Type: Single Plinth Blender with Intensifier

- Blender Limitation Time: 60 Minutes

- Blender Rotating Speed: 4-16 RPM

- Intensifier Speed: Up to 3000 RPM

- Electric Motor: 11kW (Approx. 14.75 HP)

- Voltage: 3/60/460V

- Control System: Allen-Bradley Micrologix PLC with Compact 600 HMI

- Included Components:

- Single Plinth Blender

- Intensifier Lid

- Intensifier Handling Trolley

- Operator Safety Fence

- Manual IBC Fill Unit

- Cone Clamp Station

- Control Panel

- IBC Discharge System with Discharge Station, Load Cells, Weigh Amplifier, Control System

- IBC Tanks: (5) 2700L S13 Stainless Steel IBCs with NIR Mounting

Applications

- Pharmaceutical powder blending

- Nutraceutical ingredient mixing

- Food industry powder blending

- Dry chemical blending

- Dairy powder mixing

- Specialty powders and granules blending

- Nutrient and supplement production

- High-value product containment and processing

- Contamination-sensitive mixing applications

- Scalable batch powder manufacturing

Products This System Can Be Used For

- Pharmaceutical tablets and powders

- Nutraceutical and dietary supplement blends

- Protein powders and meal replacements

- Food ingredients (spices, cocoa, flour blends)

- Chemical powders and resins

- Dairy powders and infant formula

- Cosmetic powders

- Plastic granules and additives

- Agricultural powders and seeds

- Specialty custom powder formulations

Blending, Granular Materials, Granular products, Granulating, Granules, Powder Production, Powders

- Matcon IBC blending system

- 2700L stainless steel IBC blender

- Unused Matcon blender for sale

- Industrial powder blending system

- IBC blender with intensifier

- High capacity powder mixing system

- Matcon blending equipment 2021

- Allen-Bradley controlled blender

- Food-grade IBC blending system

- Pharmaceutical powder mixer

- IBC blender

- Industrial blending system

- Powder blending equipment

- Stainless steel blender

- Matcon powder blender

- Pharmaceutical mixer

- Nutraceutical blending equipment

- Food-grade IBC mixer

- Unused powder blending system

- Industrial intensifier blender

- Buy Matcon IBC blending system

- Unused powder blender for sale

- 2700L stainless steel IBC blender available

- Industrial blending system dealer

- Sell high-capacity powder blenders

- Matcon blender with intensifier for sale

- Pharmaceutical and nutraceutical blender

- IBC blending equipment supplier

- 2021 Matcon blender in stock

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory