Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

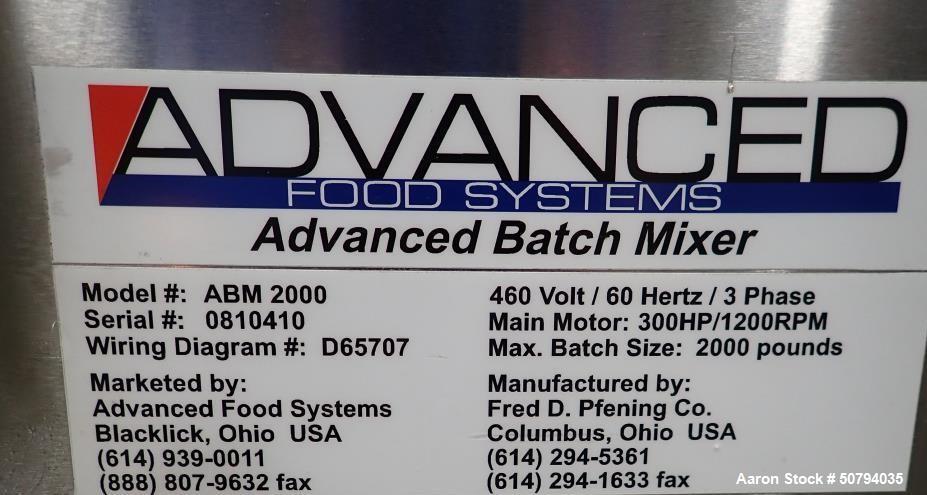

Advanced Food Systems 2000 lb High Speed Batch Mixer

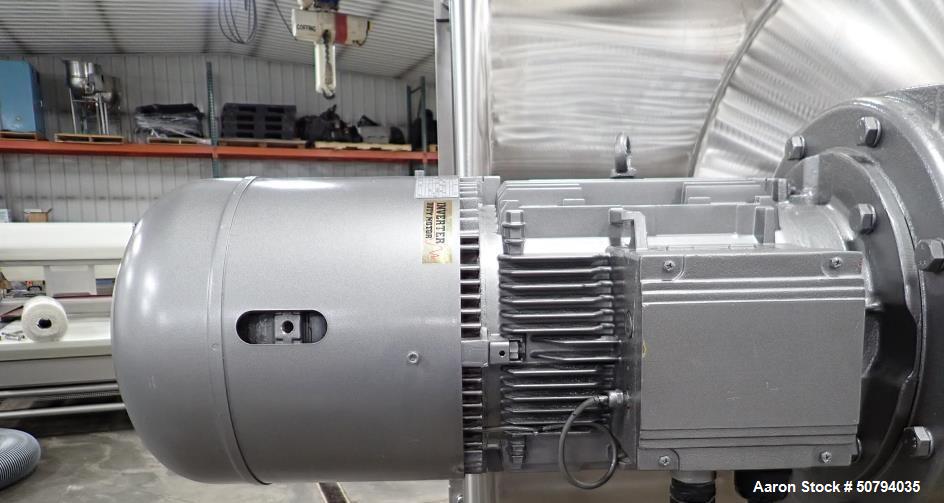

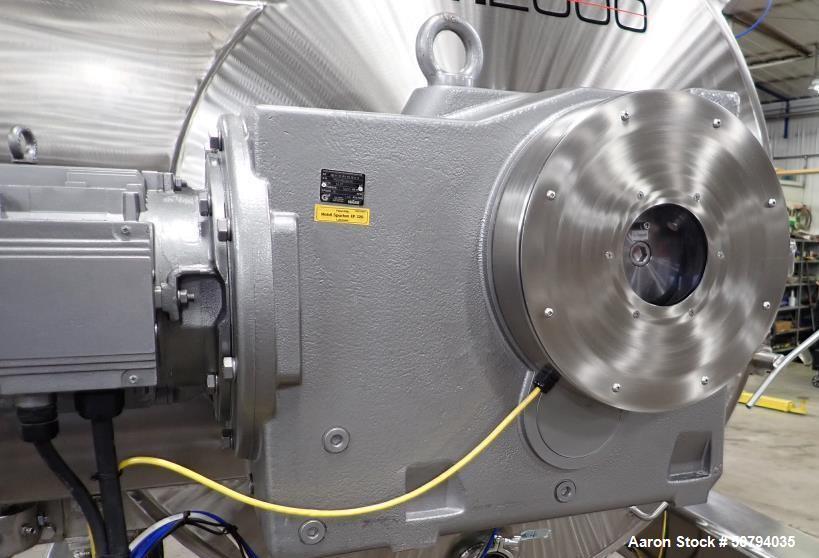

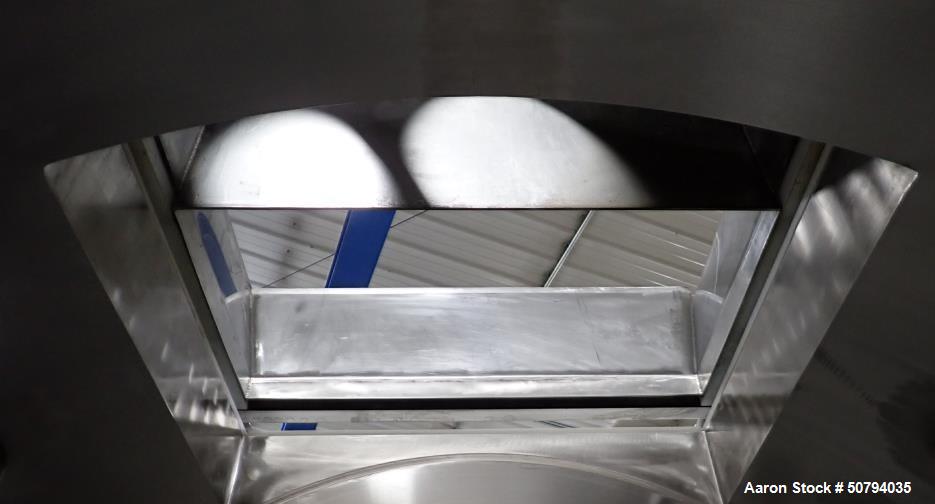

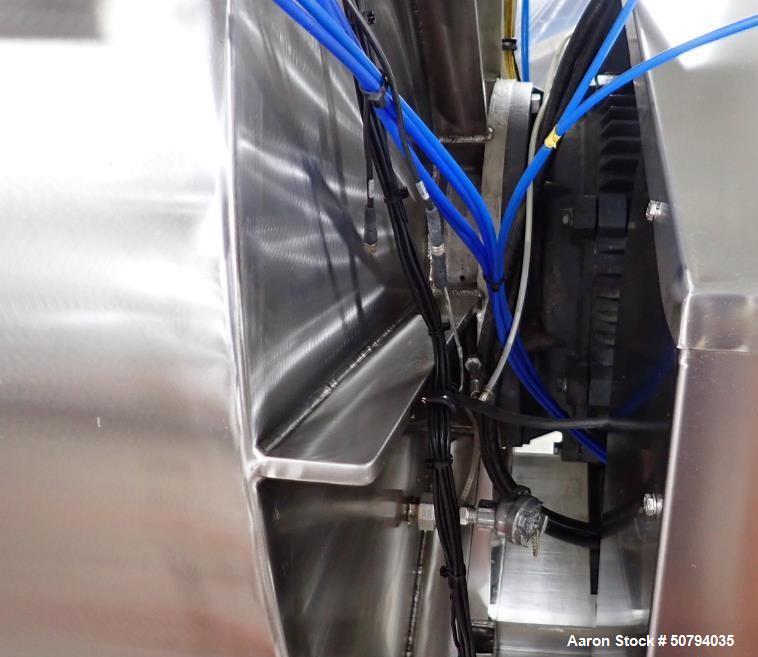

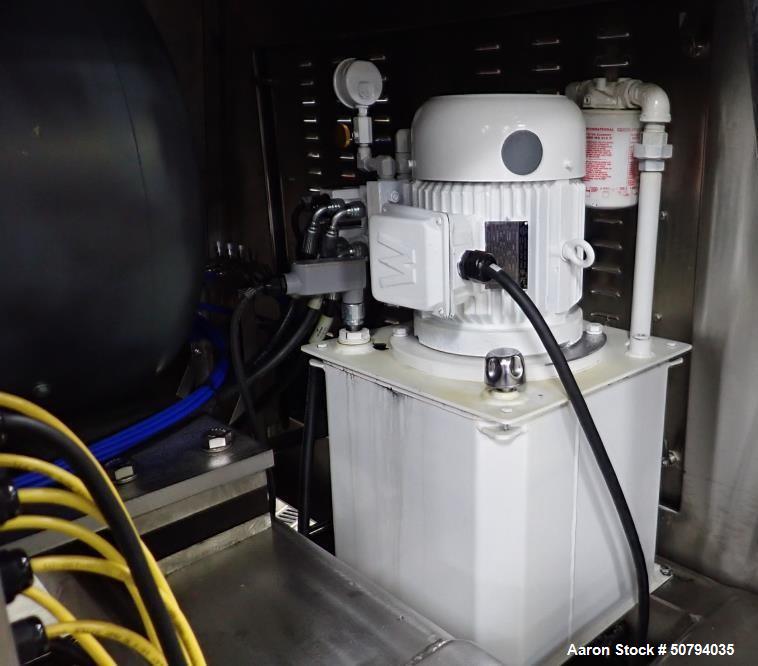

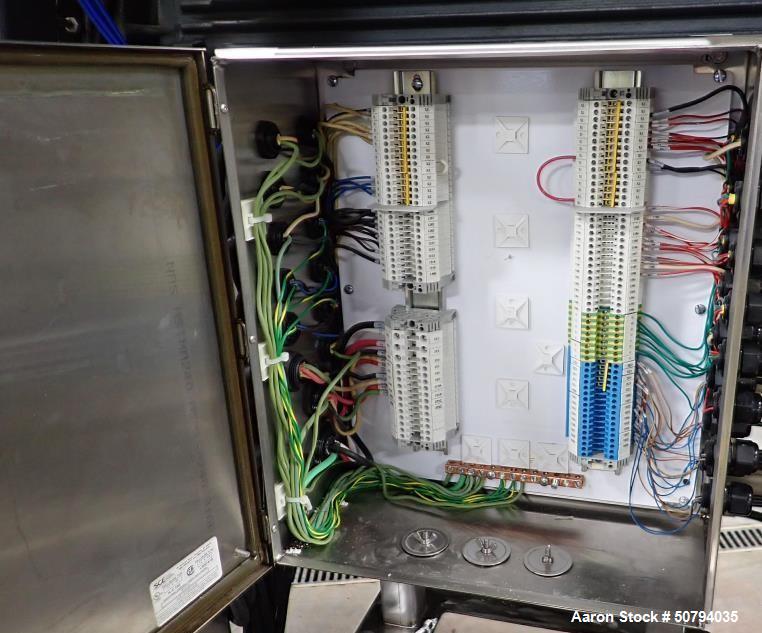

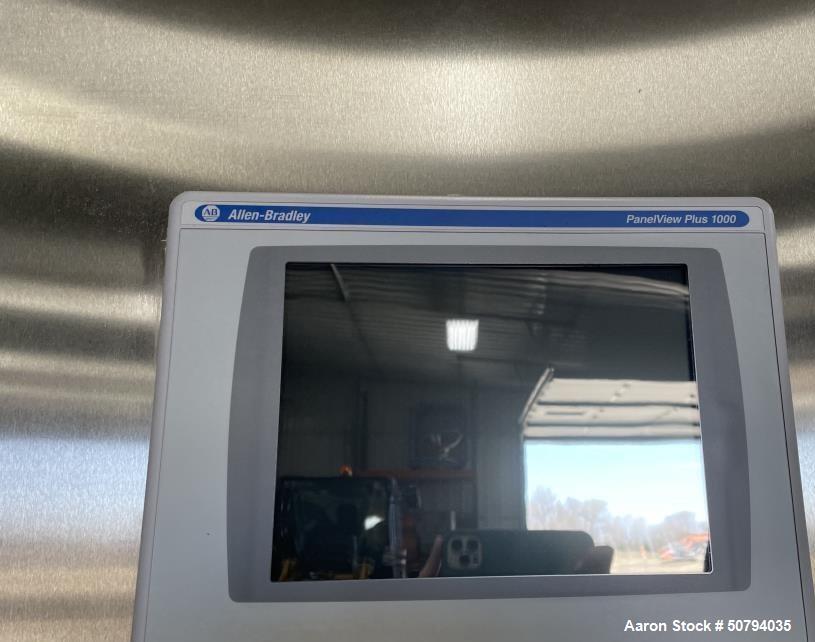

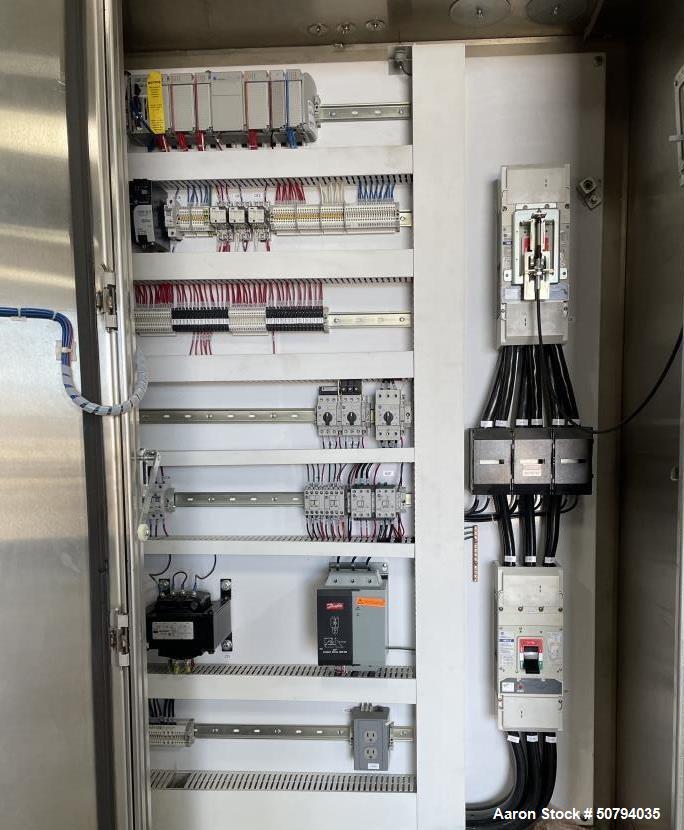

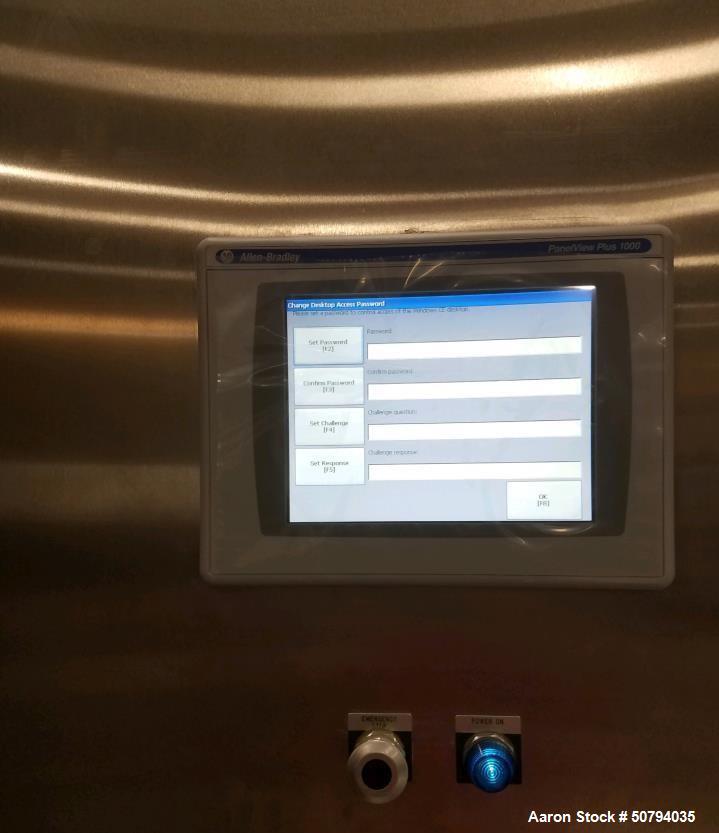

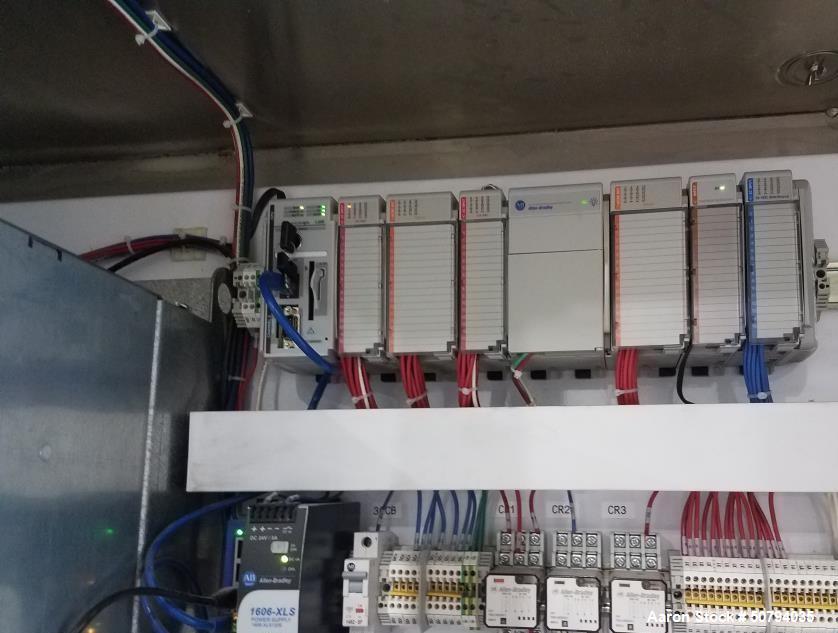

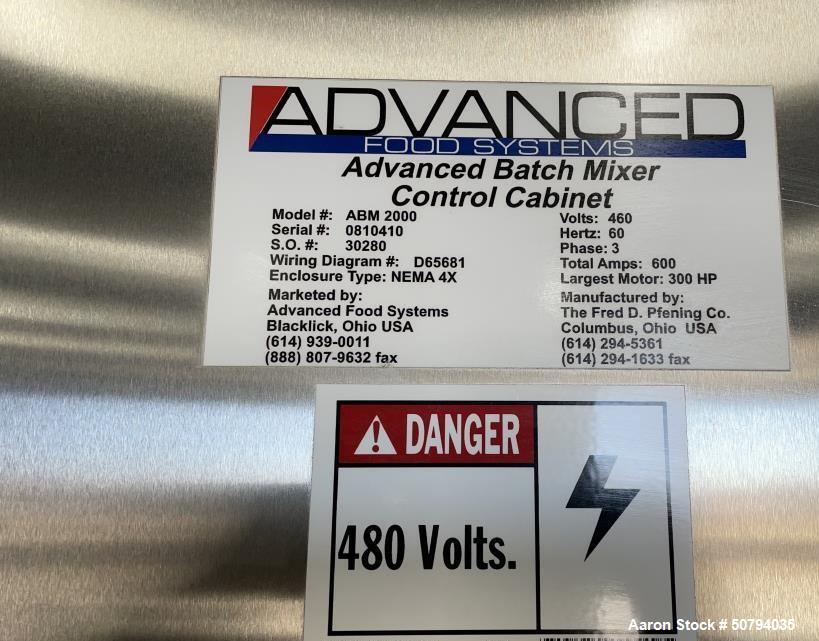

Used Advanced Food Systems 2000 lb High Speed Batch Mixer. All stainless-steel construction. Batch sizes range from 1100 lbs. to 2000 lbs. Mixing chamber is 58 in. diameter x 38 in. deep. Bi-directional scrapper arm. Current hopper 21 in. long x 38 in. wide x 16 in. deep with (1) 10 in. diameter and (1) 8 in. diameter inlet. Could fit a hopper up to 26.5 in. long x 33 in. wide. Has hydraulically operated UHMW plastic slide gate at the top for dry ingredients, 33 in. long x 35 in. wide. Has (5) 4 in. diameter liquid inlet ports on the upper portion of the mixer and (1) on the door. Hydraulically operated stainless steel slide gate, 25 in. long x 17 in. wide, with 36 in. clearance to the floor. Mixer is mounted on 8 in. stainless steel square tubing legs. Current legs are 32 in. tall, with option for additional 29 in. extensions. TEFC, VFD rated main motor for turning processing tools is 50-1200rpm / 300hp / 460volt / 60hz. SS electrical cabinet. NEMA 4X stainless steel, wash down rated mixer control cabinet housing the Allen Bradley CompactLogix PLC, I/O racks, VFD speed control for main motor and other motor starters. Allen Bradley PanelView plus 1000 color touch screen.

Overview

This Used Advanced Food Systems High Speed Batch Mixer is a robust, heavy-duty mixer designed for high-volume mixing of dry and liquid ingredients. With a batch capacity ranging from 1100 lbs to 2000 lbs, this unit is ideal for applications requiring rapid, thorough blending.

Built with all stainless steel construction, this mixer ensures sanitary processing and is suitable for food, nutraceutical, pharmaceutical, and chemical industries. The system includes a hydraulically operated UHMW plastic slide gate for dry ingredient loading and a hydraulic discharge gate, all controlled by a 300 HP TEFC VFD-rated main motor.

The mixer is equipped with an Allen Bradley CompactLogix PLC, PanelView Plus 1000 touchscreen, and NEMA 4X stainless steel washdown electrical enclosure, offering user-friendly control and system integration.

Key Specifications

- Manufacturer: Advanced Food Systems

- Capacity: 2000 lbs (Batch size: 1100 lbs - 2000 lbs)

- Construction: All Stainless Steel

- Mixing Chamber Dimensions: 58" Diameter x 38" Deep

- Hopper Dimensions (Current):

- 21" Long x 38" Wide x 16" Deep

- (1) 10" Diameter Inlet

- (1) 8" Diameter Inlet

- Hopper Capacity (Optional): Up to 26.5" Long x 33" Wide

- Dry Ingredient Loading Gate:

- Hydraulically Operated UHMW Plastic Slide Gate

- 33" Long x 35" Wide

- Liquid Inlet Ports:

- (5) 4" Diameter Ports (Upper Portion)

- (1) Liquid Port on Door

- Discharge Gate:

- Hydraulically Operated Stainless Steel Slide Gate

- 25" Long x 17" Wide

- 36" Clearance to Floor

- Support Legs:

- 8" Stainless Steel Square Tubing Legs

- 32" Tall (Additional 29" Extensions Available)

- Main Motor:

- TEFC VFD Rated

- 50 - 1200 RPM

- 300 HP / 460 Volt / 60 Hz

- Control Cabinet:

- NEMA 4X Stainless Steel, Washdown Rated

- Allen Bradley CompactLogix PLC

- Allen Bradley PanelView Plus 1000 Color Touchscreen

- VFD Speed Control for Main Motor

- Motor Starters & I/O Racks

Features & Benefits

- High-Speed, High-Capacity Mixing – Designed for rapid processing of large batch sizes up to 2000 lbs

- All Stainless Steel Construction – Ideal for sanitary food, pharmaceutical, or chemical applications

- Bi-Directional Scraper Arm – Ensures thorough mixing and prevents material buildup

- Flexible Ingredient Addition – Multiple dry and liquid inlet ports with hydraulically operated loading gates

- Precision Controls – Allen Bradley CompactLogix PLC and PanelView Plus 1000 touchscreen for user-friendly operation

- Robust Motor & VFD Drive – 300 HP TEFC motor with VFD control allows fine adjustment of processing speeds

- Sanitary & Washdown Design – NEMA 4X stainless steel electrical cabinet for hygienic environments

- Adjustable Leg Extensions – Customizable discharge height for integration with downstream equipment

Applications

- Food Products: Doughs, Batters, Spices, Protein Blends

- Nutraceutical & Pharmaceutical: Powder Blends, Granulations

- Chemical Processing: Dry Blends, Adhesives, Additives

- Pet Food & Animal Nutrition

Industries Served

- Food & Beverage Manufacturing

- Pharmaceutical & Nutraceutical Production

- Chemical & Industrial Processing

- Pet Food Manufacturing

- Batch mixer, high-speed mixer, stainless steel mixer

- 2000 lb batch mixer, Advanced Food Systems high-speed mixer, 300 HP stainless mixer

- Used Advanced Food Systems 2000 lb stainless steel high-speed batch mixer with 300 HP VFD motor and Allen Bradley controls, food-grade industrial mixer with hydraulically operated gates and PLC automation, high-capacity stainless steel batch mixer for food, pharma, and chemical applications

Used Advanced Food Systems 2000 lb High Speed Batch Mixer. All stainless-steel construction. Batch sizes range from 1100 lbs. to 2000 lbs. Mixing chamber is 58 in. diameter x 38 in. deep. Bi-directional scrapper arm. Current hopper 21 in. long x 38 in. wide x 16 in. deep with (1) 10 in. diameter and (1) 8 in. diameter inlet. Could fit a hopper up to 26.5 in. long x 33 in. wide. Has hydraulically operated UHMW plastic slide gate at the top for dry ingredients, 33 in. long x 35 in. wide. Has (5) 4 in. diameter liquid inlet ports on the upper portion of the mixer and (1) on the door. Hydraulically operated stainless steel slide gate, 25 in. long x 17 in. wide, with 36 in. clearance to the floor. Mixer is mounted on 8 in. stainless steel square tubing legs. Current legs are 32 in. tall, with option for additional 29 in. extensions. TEFC, VFD rated main motor for turning processing tools is 50-1200rpm / 300hp / 460volt / 60hz. SS electrical cabinet. NEMA 4X stainless steel, wash down rated mixer control cabinet housing the Allen Bradley CompactLogix PLC, I/O racks, VFD speed control for main motor and other motor starters. Allen Bradley PanelView plus 1000 color touch screen.

Overview

This Used Advanced Food Systems High Speed Batch Mixer is a robust, heavy-duty mixer designed for high-volume mixing of dry and liquid ingredients. With a batch capacity ranging from 1100 lbs to 2000 lbs, this unit is ideal for applications requiring rapid, thorough blending.

Built with all stainless steel construction, this mixer ensures sanitary processing and is suitable for food, nutraceutical, pharmaceutical, and chemical industries. The system includes a hydraulically operated UHMW plastic slide gate for dry ingredient loading and a hydraulic discharge gate, all controlled by a 300 HP TEFC VFD-rated main motor.

The mixer is equipped with an Allen Bradley CompactLogix PLC, PanelView Plus 1000 touchscreen, and NEMA 4X stainless steel washdown electrical enclosure, offering user-friendly control and system integration.

Key Specifications

- Manufacturer: Advanced Food Systems

- Capacity: 2000 lbs (Batch size: 1100 lbs - 2000 lbs)

- Construction: All Stainless Steel

- Mixing Chamber Dimensions: 58" Diameter x 38" Deep

- Hopper Dimensions (Current):

- 21" Long x 38" Wide x 16" Deep

- (1) 10" Diameter Inlet

- (1) 8" Diameter Inlet

- Hopper Capacity (Optional): Up to 26.5" Long x 33" Wide

- Dry Ingredient Loading Gate:

- Hydraulically Operated UHMW Plastic Slide Gate

- 33" Long x 35" Wide

- Liquid Inlet Ports:

- (5) 4" Diameter Ports (Upper Portion)

- (1) Liquid Port on Door

- Discharge Gate:

- Hydraulically Operated Stainless Steel Slide Gate

- 25" Long x 17" Wide

- 36" Clearance to Floor

- Support Legs:

- 8" Stainless Steel Square Tubing Legs

- 32" Tall (Additional 29" Extensions Available)

- Main Motor:

- TEFC VFD Rated

- 50 - 1200 RPM

- 300 HP / 460 Volt / 60 Hz

- Control Cabinet:

- NEMA 4X Stainless Steel, Washdown Rated

- Allen Bradley CompactLogix PLC

- Allen Bradley PanelView Plus 1000 Color Touchscreen

- VFD Speed Control for Main Motor

- Motor Starters & I/O Racks

Features & Benefits

- High-Speed, High-Capacity Mixing – Designed for rapid processing of large batch sizes up to 2000 lbs

- All Stainless Steel Construction – Ideal for sanitary food, pharmaceutical, or chemical applications

- Bi-Directional Scraper Arm – Ensures thorough mixing and prevents material buildup

- Flexible Ingredient Addition – Multiple dry and liquid inlet ports with hydraulically operated loading gates

- Precision Controls – Allen Bradley CompactLogix PLC and PanelView Plus 1000 touchscreen for user-friendly operation

- Robust Motor & VFD Drive – 300 HP TEFC motor with VFD control allows fine adjustment of processing speeds

- Sanitary & Washdown Design – NEMA 4X stainless steel electrical cabinet for hygienic environments

- Adjustable Leg Extensions – Customizable discharge height for integration with downstream equipment

Applications

- Food Products: Doughs, Batters, Spices, Protein Blends

- Nutraceutical & Pharmaceutical: Powder Blends, Granulations

- Chemical Processing: Dry Blends, Adhesives, Additives

- Pet Food & Animal Nutrition

Industries Served

- Food & Beverage Manufacturing

- Pharmaceutical & Nutraceutical Production

- Chemical & Industrial Processing

- Pet Food Manufacturing

- Batch mixer, high-speed mixer, stainless steel mixer

- 2000 lb batch mixer, Advanced Food Systems high-speed mixer, 300 HP stainless mixer

- Used Advanced Food Systems 2000 lb stainless steel high-speed batch mixer with 300 HP VFD motor and Allen Bradley controls, food-grade industrial mixer with hydraulically operated gates and PLC automation, high-capacity stainless steel batch mixer for food, pharma, and chemical applications

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory