Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Used Munch Pellet Mill System Consisting Of: (1) Vecoplan incline feed conveyor, approximate 60" wide x 26 long, approximate 168" discharge height, driven by a 5hp gear motor, (1) Ensign dosing hoppe...

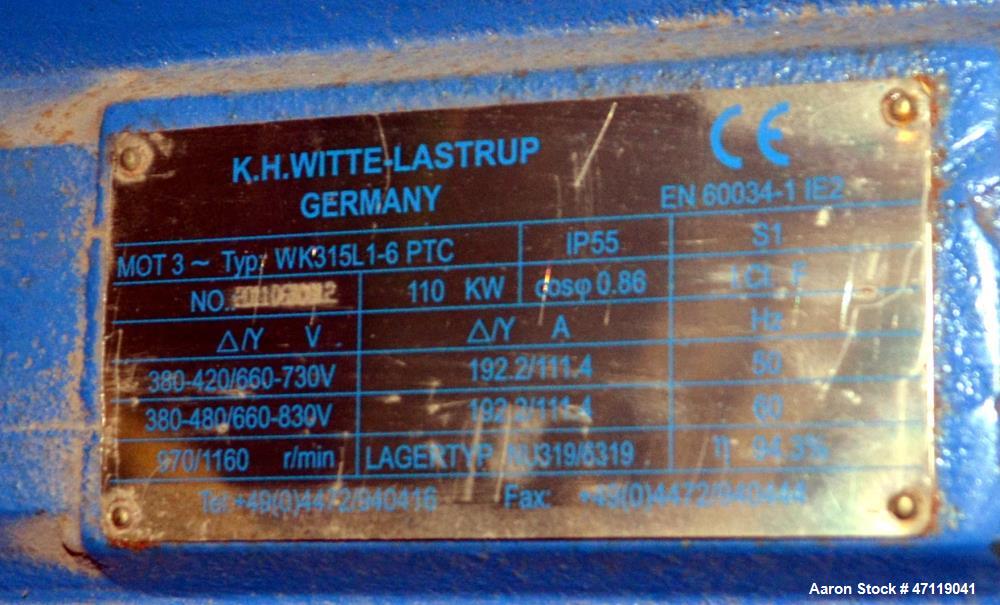

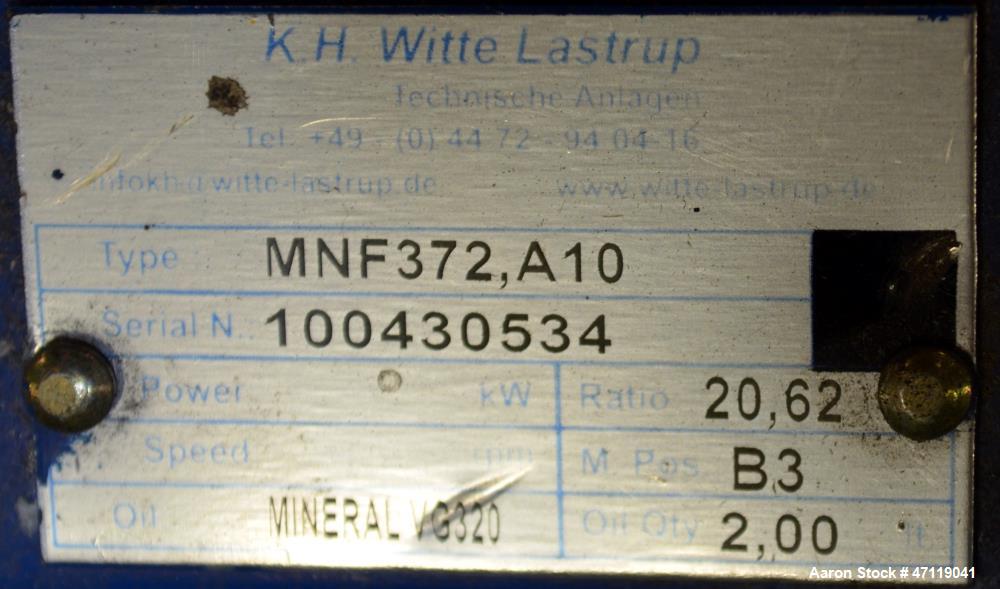

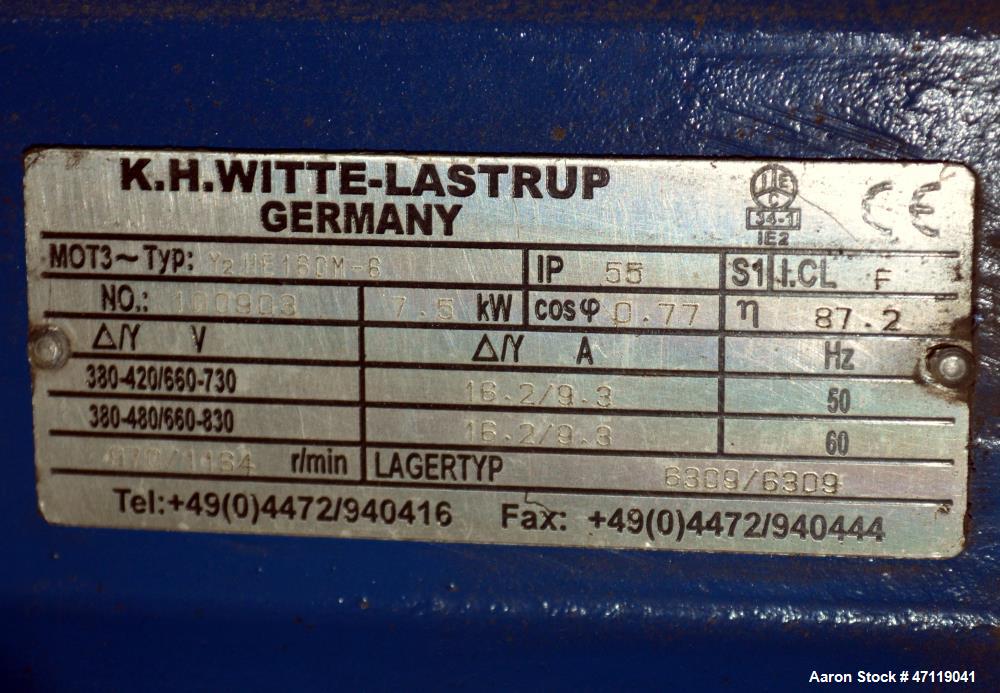

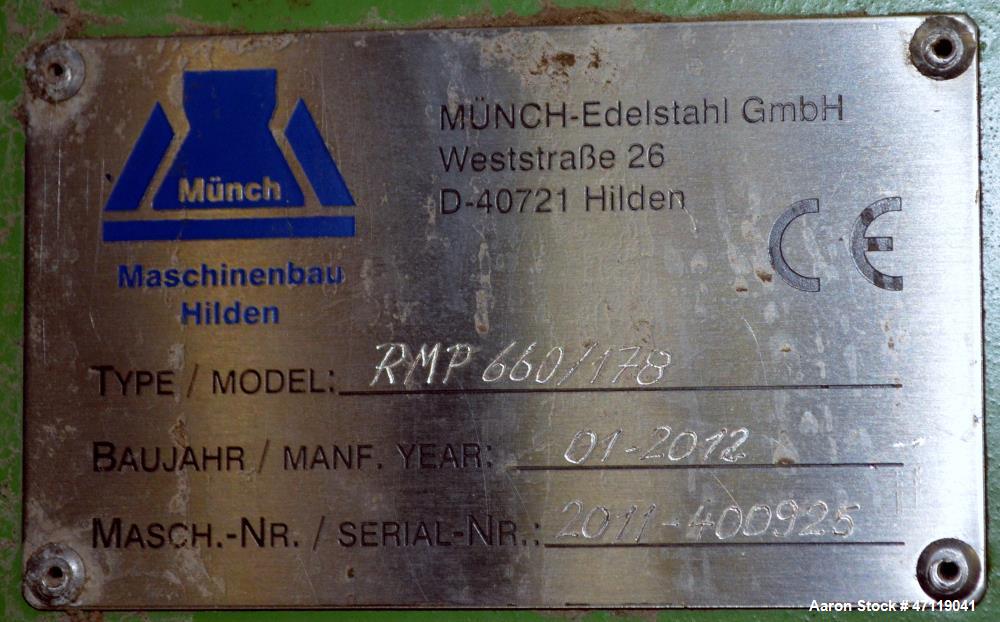

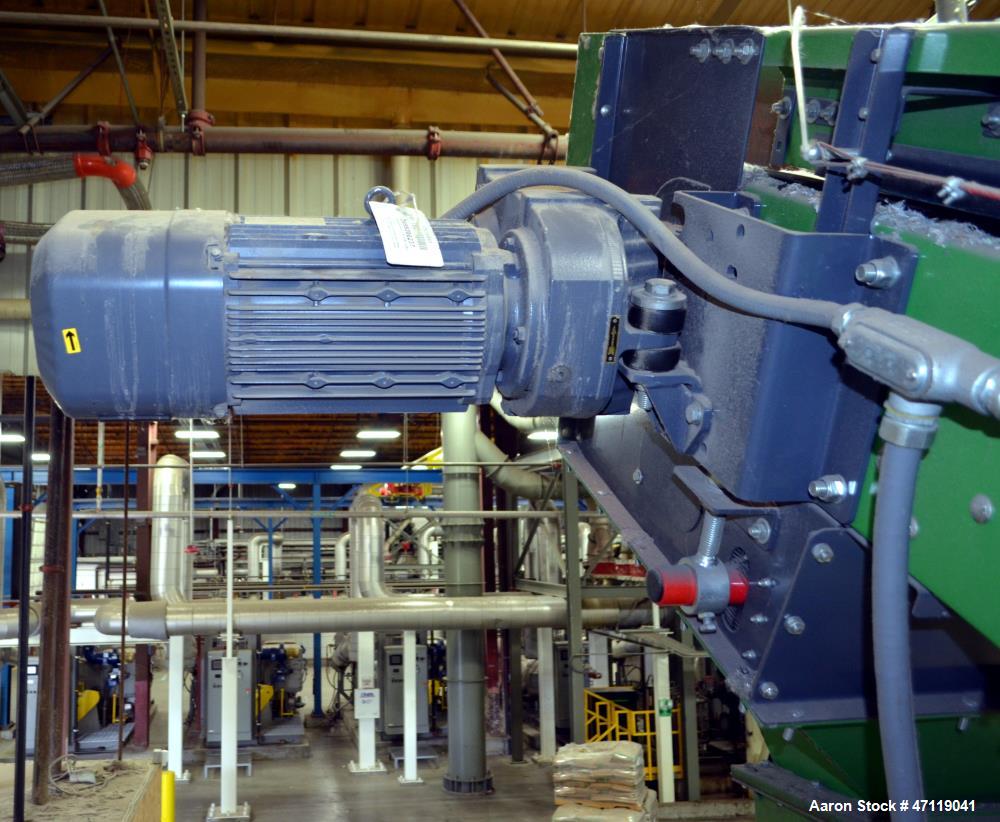

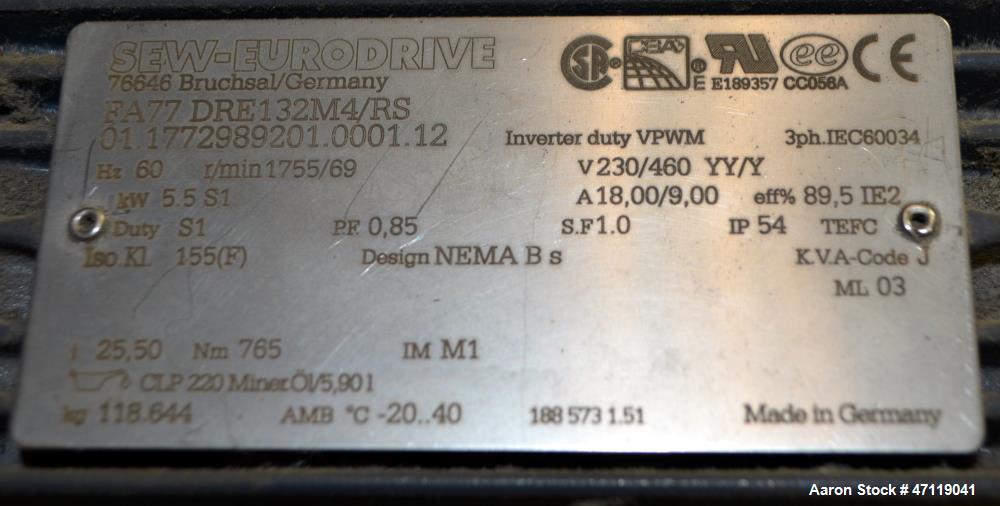

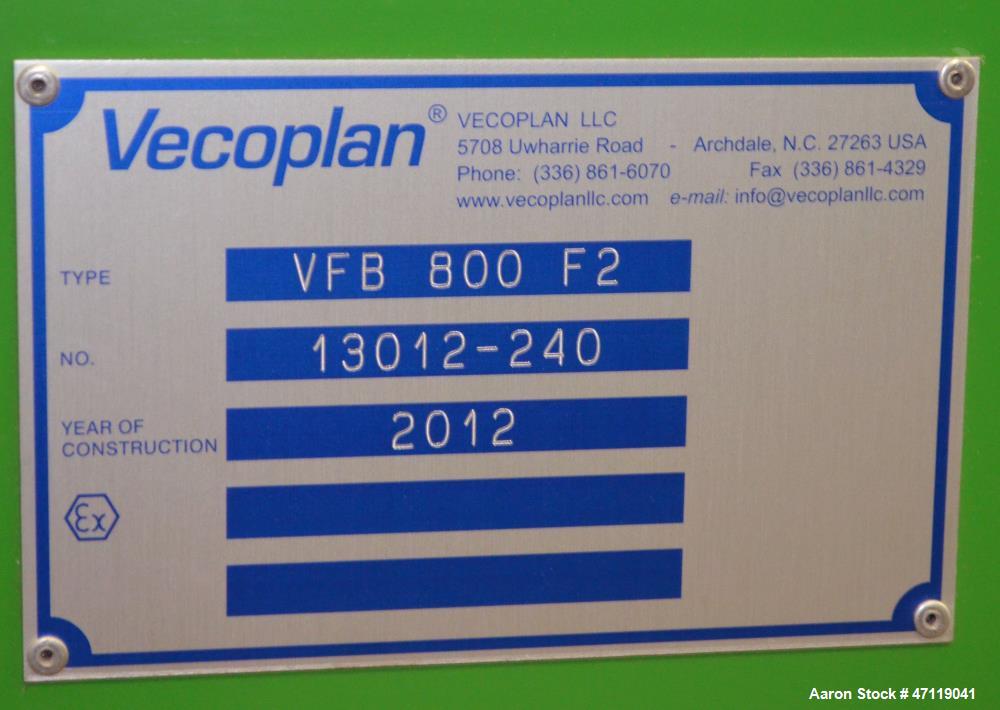

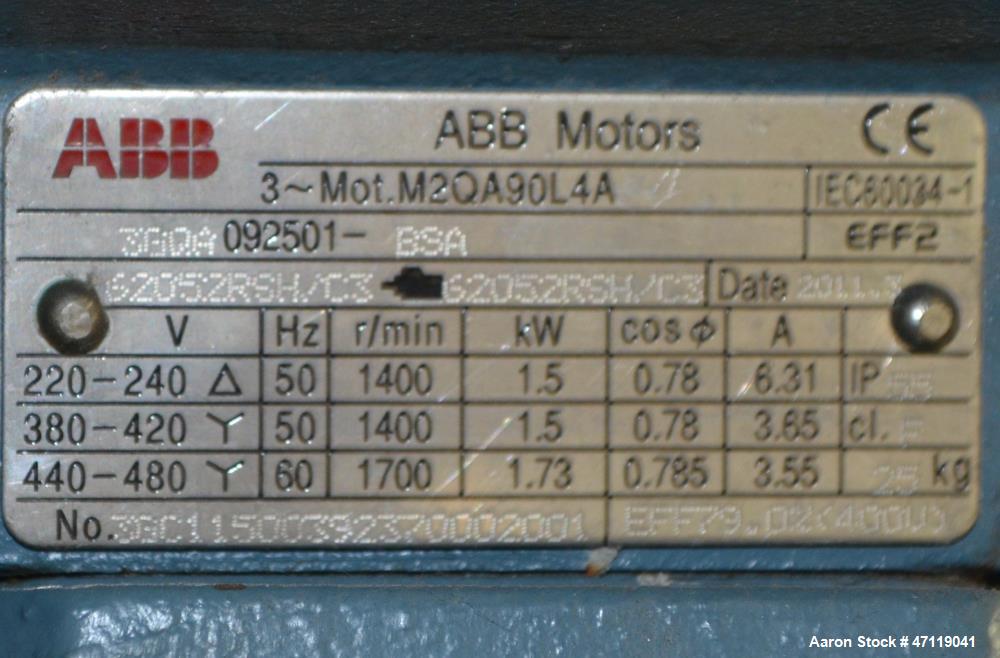

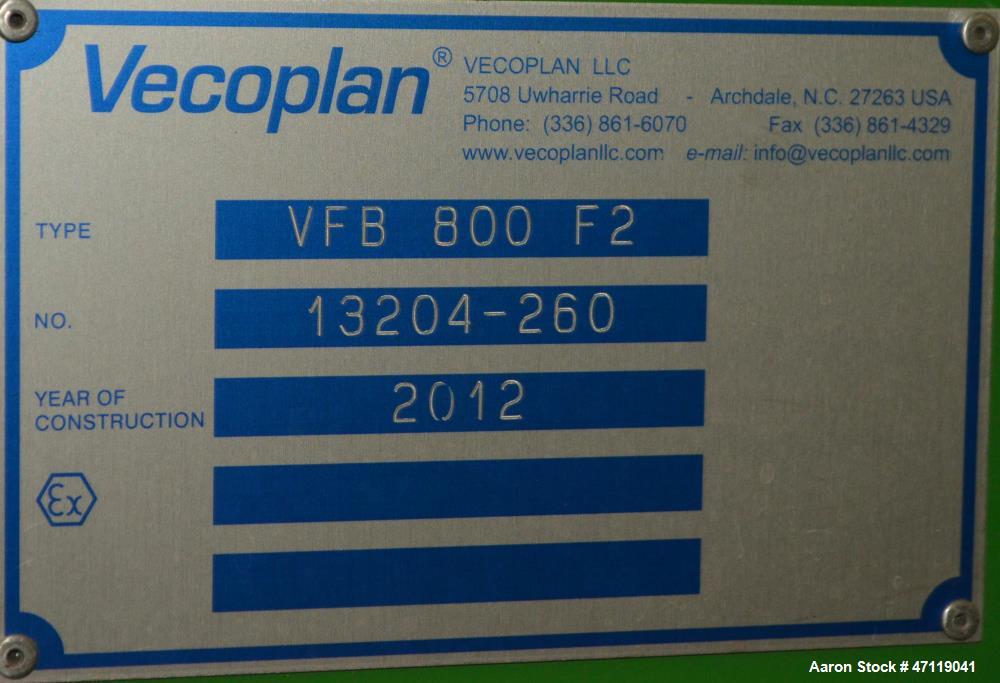

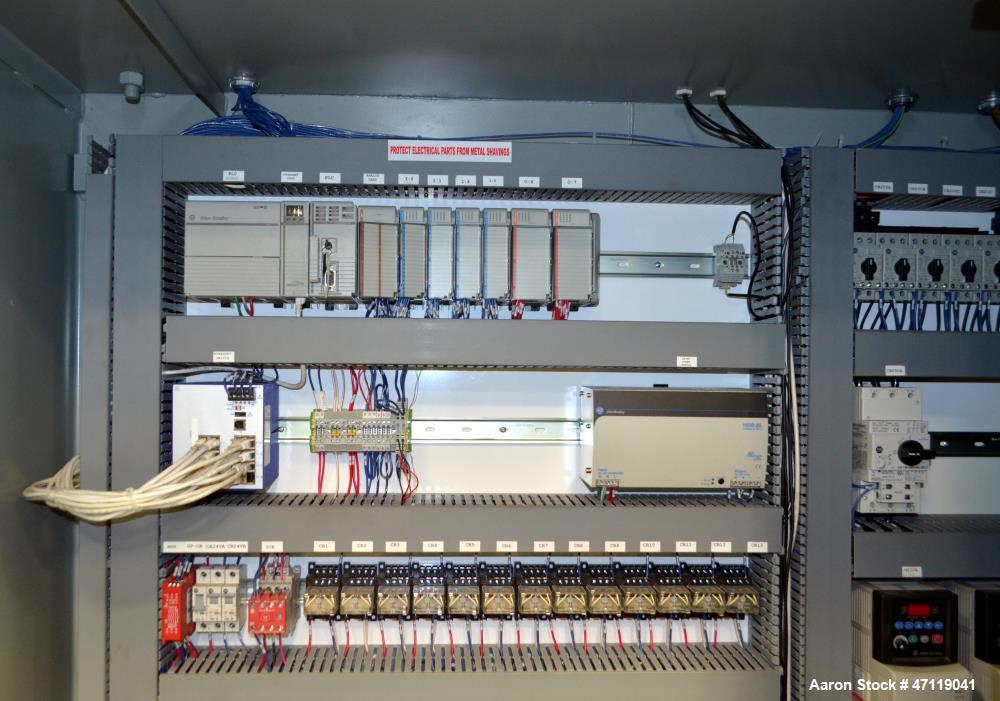

Used Munch Pellet Mill System Consisting Of: (1) Vecoplan incline feed conveyor, approximate 60" wide x 26 long, approximate 168" discharge height, driven by a 5hp gear motor, (1) Ensign dosing hopper, approximate 84" wide x 108" long x 84" deep, approximate 16" diameter x 11 long, driven by a 5hp motor with reducer, (1) Vecoplan incline conveyor, type KKF-820-2K-U, serial# 13012-210. Approximate 32" wide x 84" long bottom horizontal section x 30 long inclined section, driven by a 5hp gear motor, (1) rotary drum magnet with gear motor and discharge chute, (1) Munch densifier, approximate 60" diameter x 60" deep, bottom blade driven by an approximate 5hp motor. (1) Munch ring die pellet mill, model RMP660/178, serial# 2011-400925, built 2012. Carbon steel. (2) Approximate 12-1/2" diameter x 7-1/8" face rollers, approximate 26" inside diameter die with approximately 3/8" diameter holes. Each roll driven by a 110kw motor. Top mounted pre-conditioning feeder driven by a 3kw motor gear motor, conditioning feeder driven by a 7.5kw motor, hinged front door with discharge chute & bar feeder driven by a 1.1kw motor, includes an auto greaser. (1) Vecoplan incline conveyor, type VFB-800-F2, serial# 13012-240. Approximate 32" wide x 72" long bottom horizontal section x 30 long inclined section, driven by a 5.5kw gear motor, (1) Munch pellet cooler, model SDCC10. Top feed with rotary valve, side access door, hydraulic operated bottom slats with power pack, 30hp blower, and cyclone. (1) Vecoplan incline conveyor, type VFB-800-F2, serial# 13012-260. Approximate 32" wide x 120" long bottom horizontal section x 10 long inclined section, driven by a 3kw gear motor. Includes control panels.

Used Munch Pellet Mill System Consisting Of: (1) Vecoplan incline feed conveyor, approximate 60" wide x 26 long, approximate 168" discharge height, driven by a 5hp gear motor, (1) Ensign dosing hopper, approximate 84" wide x 108" long x 84" deep, approximate 16" diameter x 11 long, driven by a 5hp motor with reducer, (1) Vecoplan incline conveyor, type KKF-820-2K-U, serial# 13012-210. Approximate 32" wide x 84" long bottom horizontal section x 30 long inclined section, driven by a 5hp gear motor, (1) rotary drum magnet with gear motor and discharge chute, (1) Munch densifier, approximate 60" diameter x 60" deep, bottom blade driven by an approximate 5hp motor. (1) Munch ring die pellet mill, model RMP660/178, serial# 2011-400925, built 2012. Carbon steel. (2) Approximate 12-1/2" diameter x 7-1/8" face rollers, approximate 26" inside diameter die with approximately 3/8" diameter holes. Each roll driven by a 110kw motor. Top mounted pre-conditioning feeder driven by a 3kw motor gear motor, conditioning feeder driven by a 7.5kw motor, hinged front door with discharge chute & bar feeder driven by a 1.1kw motor, includes an auto greaser. (1) Vecoplan incline conveyor, type VFB-800-F2, serial# 13012-240. Approximate 32" wide x 72" long bottom horizontal section x 30 long inclined section, driven by a 5.5kw gear motor, (1) Munch pellet cooler, model SDCC10. Top feed with rotary valve, side access door, hydraulic operated bottom slats with power pack, 30hp blower, and cyclone. (1) Vecoplan incline conveyor, type VFB-800-F2, serial# 13012-260. Approximate 32" wide x 120" long bottom horizontal section x 10 long inclined section, driven by a 3kw gear motor. Includes control panels.

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory