Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

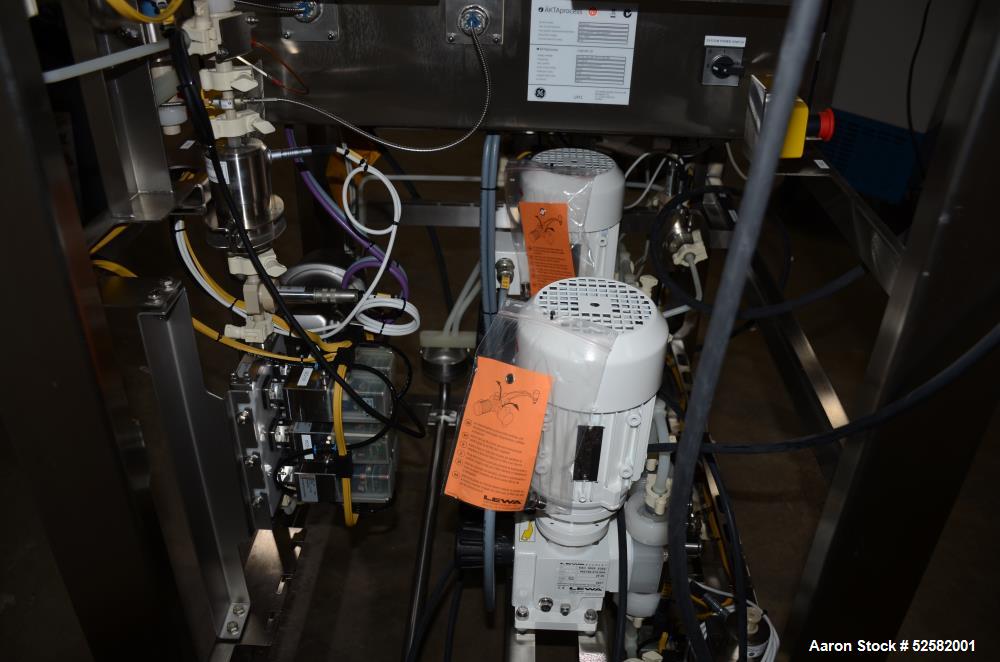

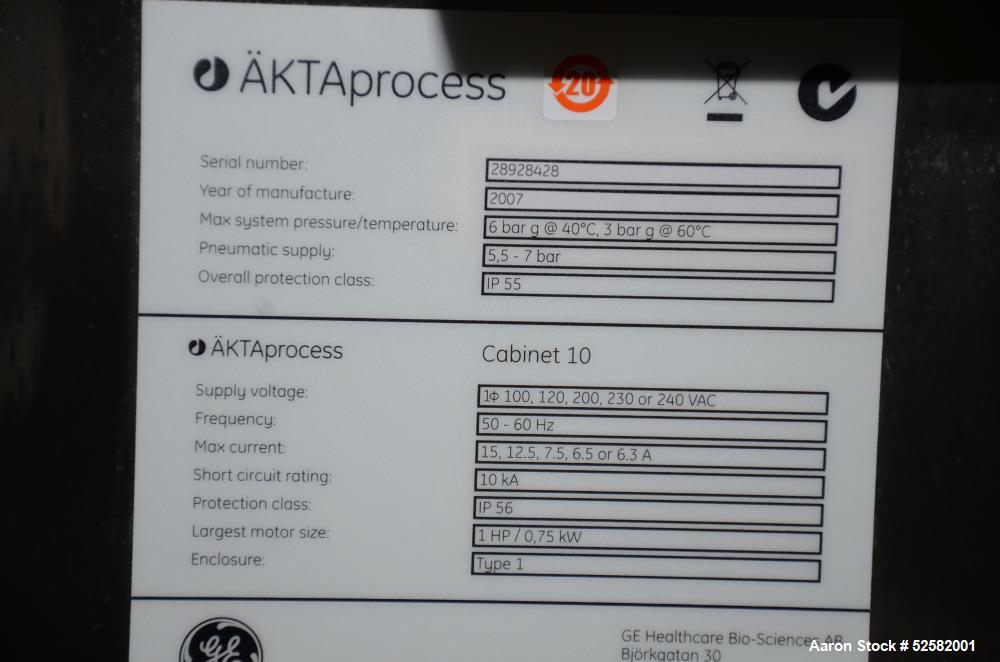

Unused - AKTA Process Liquid Chromatography System

Unused - AKTA Process Liquid Chromatography System. Process operating Inlet feed pressure: 0 to 0.2 bar (g) limits Outlet back pressure: 0 to 1 bar (g) Flammable liquids: Not allowed Operation in EX-rated environment: Not allowed Electric power Refer to Cabinet type specific data, on page 165 Compressed air Pressure 5.5 to 7 bar Airflow min. 50 Nl/min during normal operation Ingress protection EN System: IP55 60529 Cabinet: IP56, NEMA 4X Noise level = 72 dBA Floor inclination Horizontal +/- 1? Altitude Up to 2000 m Ambient environment Temperature: 2?C to 26?C Air humidity: 20% to 95%, non-condensing . Property Cabinet 10 Cabinet 30 200 to 208, 230 or 240V / 50- 60 Hz 100, 120, 200 to 208, 230 or 240V / 50-60 Hz Voltage rating Max power 1500 VA 2300 VA consumption 100, 120V: 15/16 A 15/16 A 200, 230, 240V: 10 A Minimum power supply fuse rating Transient level Overvoltage category II Overvoltage category II, Property Cabinet 10 Cabinet 30 1" polypropylene or stainless steel tubing 6 or 10 mm polypropylene tubing, 3/8" or 1/2" stainless steel tubing Tubing 180 l/h (6 mm or 3/8" tubing), 2000 l/h 600 l/h (10 mm or 1/2" tubing) Max flow rate Weight, approxi- 430 kg 825 kg mately Dimensions, 125 x 105 x 165 cm 220 x 105 x 189 cm operators console excluded. Maximum pressure Tubing material Tubing diameter Fluid temperature Polypropylene All 4?C to 40?C 6 bar* 40?C to 60?C 3 bar Stainless steel 3/8", 1/2" 4?C to 40?C 10 bar* 1" 6 bar* All 40?C to 60?C 3 bar 60?C to 80?C 1 bar. Flow path section System tubing diameter 6 mm to 3/8" 10 mm to 1/2" 1" From the inlets to the column 300 ml 550 ml 2250 ml (Air trap, Filter and Column(s) bypassed) From the column to the UV cell 22 ml 47 ml 590 ml From the UV cell to the outlets 23 ml 33 ml 350 ml Air trap 1200 ml 1200 ml 1800 ml Filter housing (empty) 440 ml 450 ml 2700 ml.

Unused - AKTA Process Liquid Chromatography System. Process operating Inlet feed pressure: 0 to 0.2 bar (g) limits Outlet back pressure: 0 to 1 bar (g) Flammable liquids: Not allowed Operation in EX-rated environment: Not allowed Electric power Refer to Cabinet type specific data, on page 165 Compressed air Pressure 5.5 to 7 bar Airflow min. 50 Nl/min during normal operation Ingress protection EN System: IP55 60529 Cabinet: IP56, NEMA 4X Noise level = 72 dBA Floor inclination Horizontal +/- 1? Altitude Up to 2000 m Ambient environment Temperature: 2?C to 26?C Air humidity: 20% to 95%, non-condensing . Property Cabinet 10 Cabinet 30 200 to 208, 230 or 240V / 50- 60 Hz 100, 120, 200 to 208, 230 or 240V / 50-60 Hz Voltage rating Max power 1500 VA 2300 VA consumption 100, 120V: 15/16 A 15/16 A 200, 230, 240V: 10 A Minimum power supply fuse rating Transient level Overvoltage category II Overvoltage category II, Property Cabinet 10 Cabinet 30 1" polypropylene or stainless steel tubing 6 or 10 mm polypropylene tubing, 3/8" or 1/2" stainless steel tubing Tubing 180 l/h (6 mm or 3/8" tubing), 2000 l/h 600 l/h (10 mm or 1/2" tubing) Max flow rate Weight, approxi- 430 kg 825 kg mately Dimensions, 125 x 105 x 165 cm 220 x 105 x 189 cm operators console excluded. Maximum pressure Tubing material Tubing diameter Fluid temperature Polypropylene All 4?C to 40?C 6 bar* 40?C to 60?C 3 bar Stainless steel 3/8", 1/2" 4?C to 40?C 10 bar* 1" 6 bar* All 40?C to 60?C 3 bar 60?C to 80?C 1 bar. Flow path section System tubing diameter 6 mm to 3/8" 10 mm to 1/2" 1" From the inlets to the column 300 ml 550 ml 2250 ml (Air trap, Filter and Column(s) bypassed) From the column to the UV cell 22 ml 47 ml 590 ml From the UV cell to the outlets 23 ml 33 ml 350 ml Air trap 1200 ml 1200 ml 1800 ml Filter housing (empty) 440 ml 450 ml 2700 ml.

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory