Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Used Oberlin Model OBF12 Automatic Pressure Filter System – 12 Sq. Ft., 45 PSI

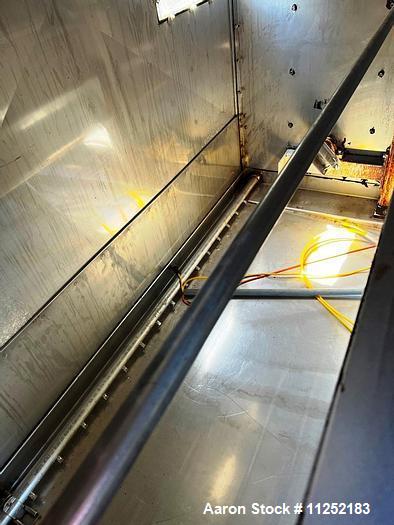

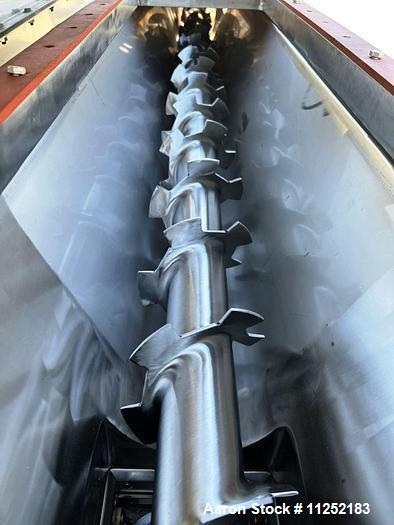

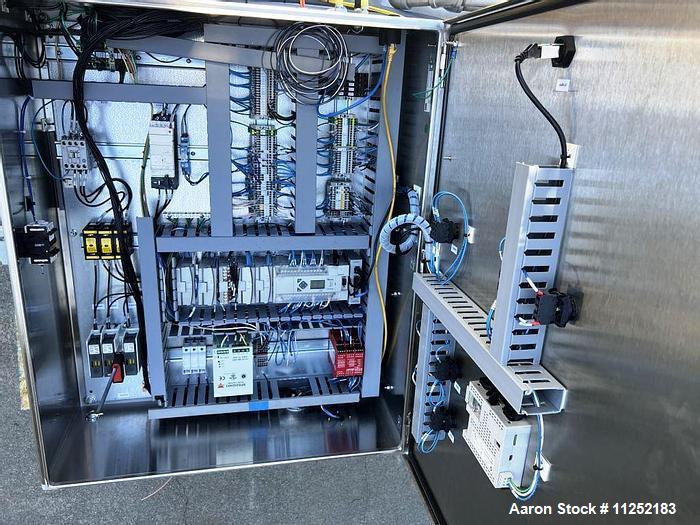

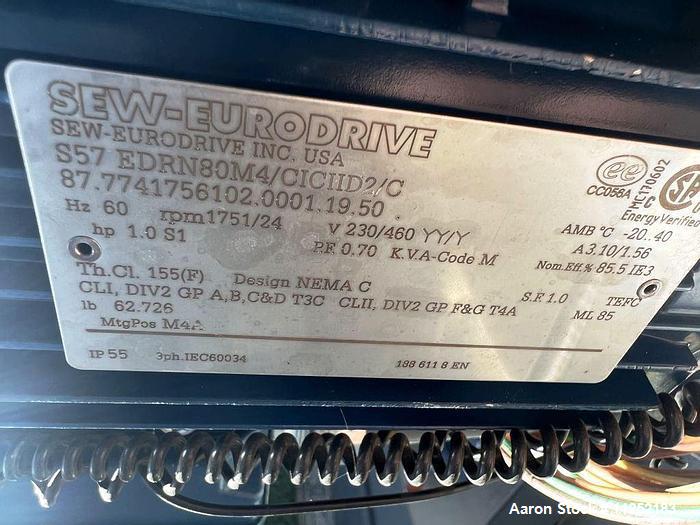

Used Oberlin Model OBF12 Automatic Pressure Filter System with reusable belt, vapor-tight stainless steel enclosure, including 316L stainless steel wetted parts. Filter is rated for 12 square feet of surface area, 45 PSI, 160 degrees Fahrenheit, approximately 40 gallons per minute, depending on application. The filter pumps dirty liquid through a tight media in a self-contained chamber, solids build into a cake on the media which catch more solids. Pressure continues to force the liquid through the densely packed cake and media. The filter pressurizes the liquid by pumping it into a chamber whose only outlet is through the unwanted solids on the media. The packed solids are discharged onto a reusable belt that conveys the solids into stainless steel hopper with horizontal, segmented screw to break-up and convey material to vertical auger discharge. Includes CIP spray bar to clean belt after solids are discharged Offered with PLC sequence control panel, gas-distribution panel, main electric disconnect panel and various other control panels. New in 2019.

Manufacturer Information:

- Manufacturer: Oberlin

- Model: OBF12

- Year Built: 2019

Description:

This used Oberlin Model OBF12 Automatic Pressure Filter System is a high-performance liquid filtration system designed for efficient solid-liquid separation. Featuring 12 square feet of filtration surface area, this system operates at 45 PSI and up to 160°F, handling approximately 40 gallons per minute, depending on the application.

The filter system includes a vapor-tight stainless steel enclosure with 316L stainless steel wetted parts, ensuring durability and corrosion resistance. The reusable filter belt efficiently separates solids by forming a densely packed cake that enhances filtration efficiency. Solids are discharged onto a conveyor belt, which transports them into a stainless steel hopper, where a horizontal segmented screw breaks up material and feeds it into a vertical auger discharge.

Additional features include a CIP spray bar for automated cleaning of the filter belt, a PLC sequence control panel, a gas-distribution panel, and a main electric disconnect panel.

Specifications:

- Filter Surface Area: 12 square feet

- Operating Pressure: 45 PSI

- Maximum Temperature: 160°F

- Flow Rate: ~40 GPM (application-dependent)

- Construction: Vapor-tight stainless steel enclosure

- Wetted Parts: 316L stainless steel

- Filtration Process: Reusable filter belt with automatic cake discharge

- Solids Handling: Stainless steel hopper with segmented screw and vertical auger discharge

- Cleaning System: CIP spray bar for belt cleaning

- Controls:

- PLC sequence control panel

- Gas-distribution panel

- Main electric disconnect panel

- Additional control panels

- Year Manufactured: 2019

Applications:

- Industrial wastewater treatment

- Metalworking coolant filtration

- Chemical and pharmaceutical processing

- Food and beverage filtration

- Paint and pigment processing

- Sludge dewatering

Products That Would Use This Machine:

- Industrial slurries and wastewater

- Metalworking fluids and cutting oils

- Chemical process liquids

- Paints, pigments, and coatings

- Food and beverage process waste

- Used Oberlin pressure filter

- OBF12 automatic pressure filter

- Industrial liquid filtration system

- Stainless steel pressure filter

- Wastewater filtration equipment

- Industrial solids separation system

- 12 sq. ft. pressure filter for sale

- Oberlin automatic filtration system

- Metalworking fluid filter

- Chemical processing filter system

Used Oberlin Model OBF12 Automatic Pressure Filter System with reusable belt, vapor-tight stainless steel enclosure, including 316L stainless steel wetted parts. Filter is rated for 12 square feet of surface area, 45 PSI, 160 degrees Fahrenheit, approximately 40 gallons per minute, depending on application. The filter pumps dirty liquid through a tight media in a self-contained chamber, solids build into a cake on the media which catch more solids. Pressure continues to force the liquid through the densely packed cake and media. The filter pressurizes the liquid by pumping it into a chamber whose only outlet is through the unwanted solids on the media. The packed solids are discharged onto a reusable belt that conveys the solids into stainless steel hopper with horizontal, segmented screw to break-up and convey material to vertical auger discharge. Includes CIP spray bar to clean belt after solids are discharged Offered with PLC sequence control panel, gas-distribution panel, main electric disconnect panel and various other control panels. New in 2019.

Manufacturer Information:

- Manufacturer: Oberlin

- Model: OBF12

- Year Built: 2019

Description:

This used Oberlin Model OBF12 Automatic Pressure Filter System is a high-performance liquid filtration system designed for efficient solid-liquid separation. Featuring 12 square feet of filtration surface area, this system operates at 45 PSI and up to 160°F, handling approximately 40 gallons per minute, depending on the application.

The filter system includes a vapor-tight stainless steel enclosure with 316L stainless steel wetted parts, ensuring durability and corrosion resistance. The reusable filter belt efficiently separates solids by forming a densely packed cake that enhances filtration efficiency. Solids are discharged onto a conveyor belt, which transports them into a stainless steel hopper, where a horizontal segmented screw breaks up material and feeds it into a vertical auger discharge.

Additional features include a CIP spray bar for automated cleaning of the filter belt, a PLC sequence control panel, a gas-distribution panel, and a main electric disconnect panel.

Specifications:

- Filter Surface Area: 12 square feet

- Operating Pressure: 45 PSI

- Maximum Temperature: 160°F

- Flow Rate: ~40 GPM (application-dependent)

- Construction: Vapor-tight stainless steel enclosure

- Wetted Parts: 316L stainless steel

- Filtration Process: Reusable filter belt with automatic cake discharge

- Solids Handling: Stainless steel hopper with segmented screw and vertical auger discharge

- Cleaning System: CIP spray bar for belt cleaning

- Controls:

- PLC sequence control panel

- Gas-distribution panel

- Main electric disconnect panel

- Additional control panels

- Year Manufactured: 2019

Applications:

- Industrial wastewater treatment

- Metalworking coolant filtration

- Chemical and pharmaceutical processing

- Food and beverage filtration

- Paint and pigment processing

- Sludge dewatering

Products That Would Use This Machine:

- Industrial slurries and wastewater

- Metalworking fluids and cutting oils

- Chemical process liquids

- Paints, pigments, and coatings

- Food and beverage process waste

- Used Oberlin pressure filter

- OBF12 automatic pressure filter

- Industrial liquid filtration system

- Stainless steel pressure filter

- Wastewater filtration equipment

- Industrial solids separation system

- 12 sq. ft. pressure filter for sale

- Oberlin automatic filtration system

- Metalworking fluid filter

- Chemical processing filter system

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory