Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Pre-Owned Rotary Steam Dryer by Drying Solutions – 7.3 MMBTU/hr, Co-Current Flow

Used Drying Solutions Rotary Steam Dryer. 304 Stainless steel construction; Rated at 1500 lbs/hr capacity with co-current single-pass superheated steam; 900 lb/hr. evaporation rate; Set for 65% moisture in and 5% moisture out at 1500 lb/hr feed rate; 1800mm diameter x 14750mm length (5.9 D x 48.4 L) drum size; Co-current flow; Cup flights around the perimeter, hollow middle; Natural gas fired burner with controls and fire-eye, Blower, belt drive. Rated at 7.3 MMBTU/hr; Set up for steam injection or water injection; Steam heated by hot air interchanger to 680 degrees F (max. inlet temp); 1,973 acfm at 266F to 288F approx. conveying air feed; Steam usage 4087 lbs/hr at 266F (approx 25 psig); Has cyclone, vertical condenser, drag conveyer, and (3) screw conveyors; 60HP blower, 60HP conveying fan, 40 HP burner, 40HP drum motor; 460V, 200 amp electrical requirements; Controls, PLC, and touch-screen HMI built into panel; Starters and (4) VFD's located in the control cabinet. Overall footprint: 19950 mm x 11110 mm x 5000 mm (65.4 x 36.4 x 16.4 H). Built 2009. Previously used for soybean meal.

| Category | Dryers - Drying EquipmentDryers - Drying Equipment |

| Subcategory | Rotary Steam TubeRotary Steam Tube |

Manufacturer Information

- Brand: Drying Solutions

- Model: Rotary Steam Dryer

- Construction: 304 Stainless Steel

- Built: 2009

- Fuel: Natural gas-fired with steam injection capability

Description

The Drying Solutions Rotary Steam Dryer is an industrial-grade, high-capacity dryer designed for efficient drying of products such as soybean meal. Featuring 304 stainless steel construction, this system is rated for 1,500 lbs/hr capacity with co-current single-pass superheated steam. It has an evaporation rate of 900 lbs/hr, processing material with 65% inlet moisture down to 5% outlet moisture at the rated feed rate.

The drum measures 1800mm diameter x 14,750mm length (5.9’ D x 48.4’ L), designed with cup flights around the perimeter and a hollow middle. It is equipped with a 7.3 MMBTU/hr natural gas-fired burner with fire-eye, blower, and belt drive, capable of steam or water injection. Air is heated by a hot air interchanger up to 680°F, with 1,973 acfm conveying air and 4,087 lbs/hr steam usage at 266°F (approx. 25 psig).

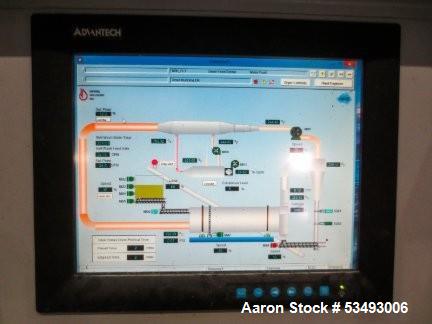

The system includes a cyclone, vertical condenser, drag conveyor, and (3) screw conveyors, along with a 60HP blower, 60HP conveying fan, 40HP burner, and 40HP drum motor. It operates on 460V, 200-amp electrical requirements, with PLC controls and touch-screen HMI integrated into the control cabinet, which also houses starters and (4) VFDs. The complete system occupies a footprint of 65.4’ x 36.4’ x 16.4’ H.

Specifications

- Capacity: 1500 lbs/hr

- Evaporation Rate: 900 lbs/hr

- Infeed Moisture: 65%

- Outlet Moisture: 5%

- Drum Size: 1800mm D x 14,750mm L (5.9’ D x 48.4’ L)

- Flow Type: Co-current single pass

- Burner Rating: 7.3 MMBTU/hr

- Max Inlet Temperature: 680°F

- Conveying Air Feed: 1,973 acfm at 266°F–288°F

- Steam Usage: 4,087 lbs/hr at 266°F (25 psig)

- Blowers & Motors:

- 60HP blower

- 60HP conveying fan

- 40HP burner

- 40HP drum motor

- Additional Equipment: Cyclone, vertical condenser, drag conveyor, (3) screw conveyors

- Electrical: 460V, 200 amps

- Controls: PLC with touch-screen HMI, starters, and (4) VFDs in control cabinet

- Footprint: 65.4’ L x 36.4’ W x 16.4’ H

- Built: 2009

- Previous Use: Soybean meal drying

Applications

- Soybean meal drying

- Oilseed meal processing

- Agricultural byproduct drying

- Biomass drying

- Food ingredient drying

- Chemical and industrial slurry drying

Compatible Products & Uses

- Soybean meal

- Canola and other oilseed meals

- Grain and agricultural byproducts

- High-moisture food ingredients

- Protein concentrates and powders

- Rotary steam dryer

- Used rotary dryer

- Drying Solutions dryer

- Steam injection dryer

- Soybean meal dryer

- Industrial rotary dryer

- Natural gas dryer

- 1500 lb/hr dryer

- Superheated steam dryer

- Co-current rotary dryer

- Drying Solutions rotary steam dryer for sale

- Industrial rotary steam dryer system

- Used 1500 lb/hr rotary steam dryer

- Natural gas-fired steam dryer with PLC controls

- Co-current rotary steam dryer with cyclone

- Agricultural meal drying equipment

- Industrial rotary drum dryer with steam injection

- High capacity soybean meal dryer

- Rotary dryer with condenser and screw conveyors

- Superheated steam rotary drying system

- Buy used Drying Solutions rotary steam dryer with 7.3 MMBTU/hr burner

- High-capacity rotary steam dryer for agricultural meal drying

- Used industrial rotary dryer for soybean meal processing

- Stainless steel rotary drum dryer with steam or water injection

- Industrial rotary drying system with control cabinet and VFDs

- Rotary steam dryer with 900 lb/hr evaporation rate for food ingredients

- Agricultural biomass rotary steam dryer for sale

- Reliable rotary drum dryer with cyclone and condenser

- Industrial rotary dryer with cup flights and hollow drum

- Pre-owned Drying Solutions rotary dryer with 65.4-foot footprint

- Used rotary steam dryer

- Industrial rotary dryer for sale

- Soybean meal dryer

- Steam injection rotary dryer

- High-capacity rotary drum dryer

- Natural gas fired dryer

- Agricultural drying equipment

- Rotary drying system

- Buy used industrial dryers

- Industrial drying machine

- Buy used rotary steam dryer

- Sell rotary drum dryer

- Used industrial drying equipment for sale

- Where to buy rotary dryers

- Natural gas rotary dryers marketplace

- Industrial soybean meal dryer supplier

- Buy and sell drying solutions dryers

- Affordable used rotary dryers

- Used rotary steam dryers for sale

- Best deals on industrial drying equipment

Used Drying Solutions Rotary Steam Dryer. 304 Stainless steel construction; Rated at 1500 lbs/hr capacity with co-current single-pass superheated steam; 900 lb/hr. evaporation rate; Set for 65% moisture in and 5% moisture out at 1500 lb/hr feed rate; 1800mm diameter x 14750mm length (5.9 D x 48.4 L) drum size; Co-current flow; Cup flights around the perimeter, hollow middle; Natural gas fired burner with controls and fire-eye, Blower, belt drive. Rated at 7.3 MMBTU/hr; Set up for steam injection or water injection; Steam heated by hot air interchanger to 680 degrees F (max. inlet temp); 1,973 acfm at 266F to 288F approx. conveying air feed; Steam usage 4087 lbs/hr at 266F (approx 25 psig); Has cyclone, vertical condenser, drag conveyer, and (3) screw conveyors; 60HP blower, 60HP conveying fan, 40 HP burner, 40HP drum motor; 460V, 200 amp electrical requirements; Controls, PLC, and touch-screen HMI built into panel; Starters and (4) VFD's located in the control cabinet. Overall footprint: 19950 mm x 11110 mm x 5000 mm (65.4 x 36.4 x 16.4 H). Built 2009. Previously used for soybean meal.

Manufacturer Information

- Brand: Drying Solutions

- Model: Rotary Steam Dryer

- Construction: 304 Stainless Steel

- Built: 2009

- Fuel: Natural gas-fired with steam injection capability

Description

The Drying Solutions Rotary Steam Dryer is an industrial-grade, high-capacity dryer designed for efficient drying of products such as soybean meal. Featuring 304 stainless steel construction, this system is rated for 1,500 lbs/hr capacity with co-current single-pass superheated steam. It has an evaporation rate of 900 lbs/hr, processing material with 65% inlet moisture down to 5% outlet moisture at the rated feed rate.

The drum measures 1800mm diameter x 14,750mm length (5.9’ D x 48.4’ L), designed with cup flights around the perimeter and a hollow middle. It is equipped with a 7.3 MMBTU/hr natural gas-fired burner with fire-eye, blower, and belt drive, capable of steam or water injection. Air is heated by a hot air interchanger up to 680°F, with 1,973 acfm conveying air and 4,087 lbs/hr steam usage at 266°F (approx. 25 psig).

The system includes a cyclone, vertical condenser, drag conveyor, and (3) screw conveyors, along with a 60HP blower, 60HP conveying fan, 40HP burner, and 40HP drum motor. It operates on 460V, 200-amp electrical requirements, with PLC controls and touch-screen HMI integrated into the control cabinet, which also houses starters and (4) VFDs. The complete system occupies a footprint of 65.4’ x 36.4’ x 16.4’ H.

Specifications

- Capacity: 1500 lbs/hr

- Evaporation Rate: 900 lbs/hr

- Infeed Moisture: 65%

- Outlet Moisture: 5%

- Drum Size: 1800mm D x 14,750mm L (5.9’ D x 48.4’ L)

- Flow Type: Co-current single pass

- Burner Rating: 7.3 MMBTU/hr

- Max Inlet Temperature: 680°F

- Conveying Air Feed: 1,973 acfm at 266°F–288°F

- Steam Usage: 4,087 lbs/hr at 266°F (25 psig)

- Blowers & Motors:

- 60HP blower

- 60HP conveying fan

- 40HP burner

- 40HP drum motor

- Additional Equipment: Cyclone, vertical condenser, drag conveyor, (3) screw conveyors

- Electrical: 460V, 200 amps

- Controls: PLC with touch-screen HMI, starters, and (4) VFDs in control cabinet

- Footprint: 65.4’ L x 36.4’ W x 16.4’ H

- Built: 2009

- Previous Use: Soybean meal drying

Applications

- Soybean meal drying

- Oilseed meal processing

- Agricultural byproduct drying

- Biomass drying

- Food ingredient drying

- Chemical and industrial slurry drying

Compatible Products & Uses

- Soybean meal

- Canola and other oilseed meals

- Grain and agricultural byproducts

- High-moisture food ingredients

- Protein concentrates and powders

| Category | Dryers - Drying Equipment |

| Subcategory | Rotary Steam Tube |

- Rotary steam dryer

- Used rotary dryer

- Drying Solutions dryer

- Steam injection dryer

- Soybean meal dryer

- Industrial rotary dryer

- Natural gas dryer

- 1500 lb/hr dryer

- Superheated steam dryer

- Co-current rotary dryer

- Drying Solutions rotary steam dryer for sale

- Industrial rotary steam dryer system

- Used 1500 lb/hr rotary steam dryer

- Natural gas-fired steam dryer with PLC controls

- Co-current rotary steam dryer with cyclone

- Agricultural meal drying equipment

- Industrial rotary drum dryer with steam injection

- High capacity soybean meal dryer

- Rotary dryer with condenser and screw conveyors

- Superheated steam rotary drying system

- Buy used Drying Solutions rotary steam dryer with 7.3 MMBTU/hr burner

- High-capacity rotary steam dryer for agricultural meal drying

- Used industrial rotary dryer for soybean meal processing

- Stainless steel rotary drum dryer with steam or water injection

- Industrial rotary drying system with control cabinet and VFDs

- Rotary steam dryer with 900 lb/hr evaporation rate for food ingredients

- Agricultural biomass rotary steam dryer for sale

- Reliable rotary drum dryer with cyclone and condenser

- Industrial rotary dryer with cup flights and hollow drum

- Pre-owned Drying Solutions rotary dryer with 65.4-foot footprint

- Used rotary steam dryer

- Industrial rotary dryer for sale

- Soybean meal dryer

- Steam injection rotary dryer

- High-capacity rotary drum dryer

- Natural gas fired dryer

- Agricultural drying equipment

- Rotary drying system

- Buy used industrial dryers

- Industrial drying machine

- Buy used rotary steam dryer

- Sell rotary drum dryer

- Used industrial drying equipment for sale

- Where to buy rotary dryers

- Natural gas rotary dryers marketplace

- Industrial soybean meal dryer supplier

- Buy and sell drying solutions dryers

- Affordable used rotary dryers

- Used rotary steam dryers for sale

- Best deals on industrial drying equipment

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory