Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Used Therma-Flite Electric-Scru Indirect Continuous Process Dryer

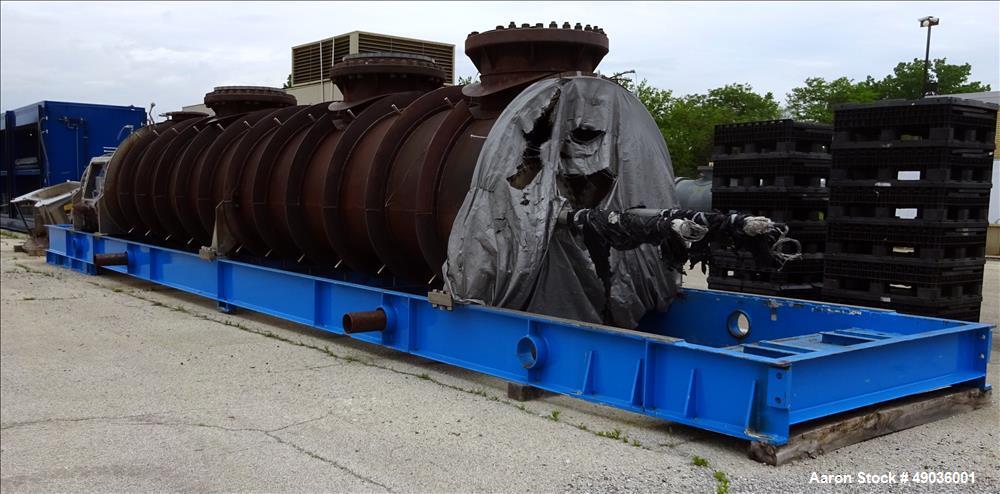

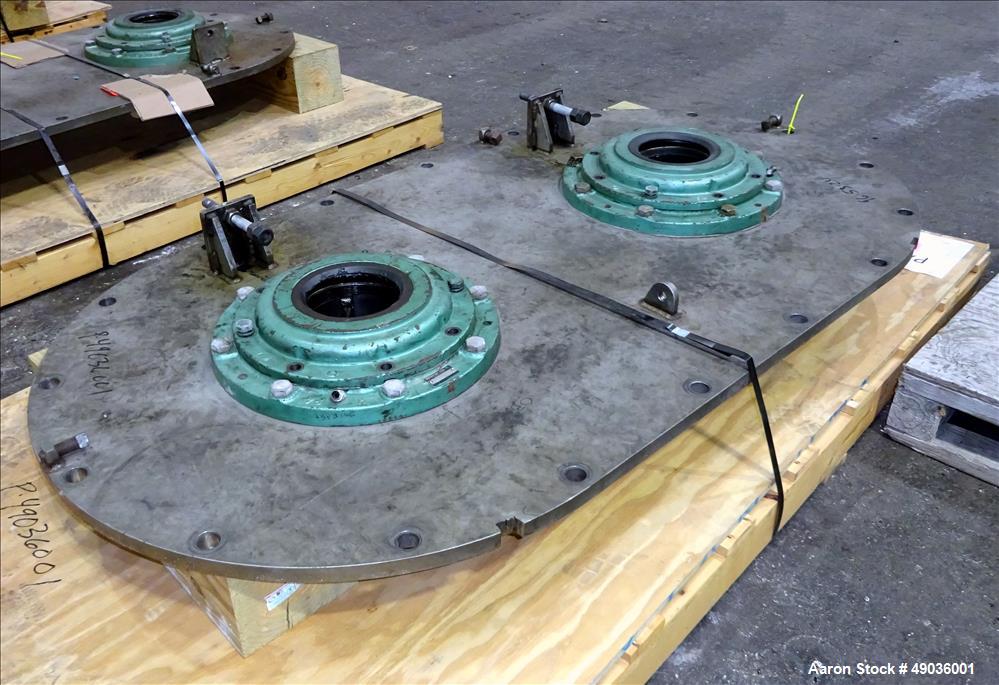

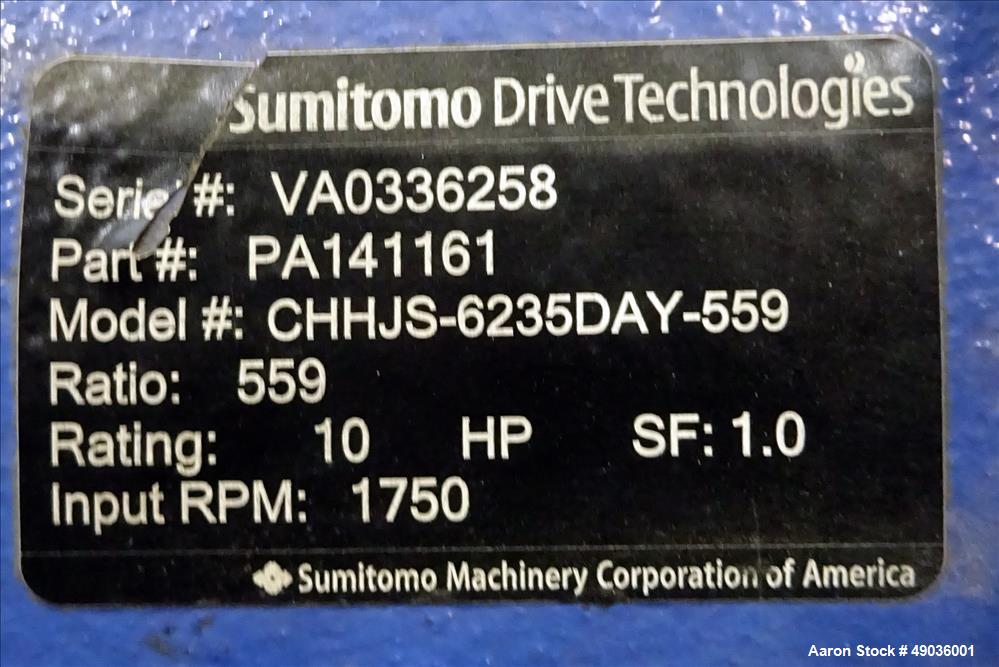

Used Therma-Flite Electric-Scru Electrically Heated Indirect Continuous Processor Dryer, Model ESD 36-30-VAR, Style A (TWIN). Chamber, Screw / Shaft is made of 316 Stainless Steel, drive and tail end plates 304 Stainless Steel. Electrically heated screw-type thermal processor with control panel. ESD 36D-30 electrically heated, twin screw conveyor with electrical resistance heaters in the housing and augers. Thermal processor for indirect heating of solids, sludges, and slurries in a continuous flow method. The unit incorporates multiple ports along the top that can be utilized to capture volatile distillates. This unit includes several premium add-ons, including zoned heating for independent heating control along with the rotor and housing. The retention time in the unit and the rate of mixing is adjustable through the HMI. There are more than a dozen TCs along with Pressure transmitters and other sensors. This unit was designed with ferrofluidic seals to maintain a high vacuum in the process chamber. It can also be converted over to operate at high-pressure in the process chamber atmosphere. It incorporates independent closed-loop drives for self-cleaning and clearing when processing materials that are sticky or tend to bake onto the heat transfer surfaces. Design Specs: Twin 36" augers, 30' in length. Approximately 1MW of heating with a maximum thermal temperature at the heating elements of 1350F. Process temperatures vary based on feed. Nominal 900F 1350F Design voltage: 480V/3Ph/60Hz. The unit saw minimal use in a pilot program to heat inorganic materials at the 900F to 1300F temperature range. Typical applications and processes for this equipment include: Drying, calcining, roasting, crystalizing, thermal desorption, and pyrolyzing. The unit can be used for remediation of soils, carbon, spent catalyst, RCRA waste and thermal processing of chemicals, carbon black, biomass, coal conversion, minerals, plastics. The equipment ships with the O&M manual certified inspection report, general arrangement, and electrical power distribution drawings. No Motor, requires approximate 10hp motor. We encourage inspection. This Dryer may not be complete with all parts.

Manufacturer Information

Brand: Therma-Flite

Model: ESD 36-30-VAR

Style: A (TWIN)

Description

The Used Therma-Flite Electric-Scru is an electrically heated, indirect continuous processor dryer designed for thermal processing of solids, sludges, and slurries. Featuring a twin screw conveyor design, this unit utilizes electrical resistance heaters integrated into the housing and augers for precise temperature control. The chamber, screw, and shaft are constructed from 316 stainless steel, while the drive and tail end plates are made from 304 stainless steel, ensuring durability and corrosion resistance. Equipped with a control panel, this electrically heated screw-type thermal processor delivers continuous and efficient drying, heating, and processing of various materials.

Specifications

- Model: ESD 36-30-VAR

- Style: A (TWIN)

- Processing Type: Indirect Heating

- Heating Method: Electrical Resistance Heaters

- Material:

- Chamber, Screw, Shaft: 316 Stainless Steel

- Drive & Tail End Plates: 304 Stainless Steel

- Function: Thermal Processing / Drying

- Control System: Integrated Control Panel

- Application: Continuous Processing of Solids, Sludges, and Slurries

Applications

This electrically heated screw-type processor is ideal for industries requiring indirect heating of materials in a continuous process. Typical applications include:

- Industrial Drying & Heating – Processing of various solids, sludges, and slurries

- Waste Treatment – Drying and volume reduction of sludge and waste materials

- Food Processing – Controlled heating of food-based materials

- Chemical Processing – Thermal treatment of chemical powders and mixtures

- Pharmaceutical Processing – Drying and stabilization of pharmaceutical materials

- Biomass & Renewable Energy – Processing of organic waste for biofuel applications

What Products Would This Be Used For?

- Industrial sludge dryers

- Wastewater treatment systems

- Chemical and pharmaceutical drying systems

- Biomass processing units

- Food and ingredient processors

- Heat treatment systems for industrial powders

Used Therma-Flite Electric-Scru, Therma-Flite ESD 36-30-VAR, electrically heated screw processor, twin screw conveyor dryer, indirect thermal processor, industrial sludge dryer, continuous process dryer, stainless steel screw conveyor, electrically heated auger, thermal processing equipment

Used Therma-Flite Electric-Scru Electrically Heated Indirect Continuous Processor Dryer, Model ESD 36-30-VAR, Style A (TWIN). Chamber, Screw / Shaft is made of 316 Stainless Steel, drive and tail end plates 304 Stainless Steel. Electrically heated screw-type thermal processor with control panel. ESD 36D-30 electrically heated, twin screw conveyor with electrical resistance heaters in the housing and augers. Thermal processor for indirect heating of solids, sludges, and slurries in a continuous flow method. The unit incorporates multiple ports along the top that can be utilized to capture volatile distillates. This unit includes several premium add-ons, including zoned heating for independent heating control along with the rotor and housing. The retention time in the unit and the rate of mixing is adjustable through the HMI. There are more than a dozen TCs along with Pressure transmitters and other sensors. This unit was designed with ferrofluidic seals to maintain a high vacuum in the process chamber. It can also be converted over to operate at high-pressure in the process chamber atmosphere. It incorporates independent closed-loop drives for self-cleaning and clearing when processing materials that are sticky or tend to bake onto the heat transfer surfaces. Design Specs: Twin 36" augers, 30' in length. Approximately 1MW of heating with a maximum thermal temperature at the heating elements of 1350F. Process temperatures vary based on feed. Nominal 900F 1350F Design voltage: 480V/3Ph/60Hz. The unit saw minimal use in a pilot program to heat inorganic materials at the 900F to 1300F temperature range. Typical applications and processes for this equipment include: Drying, calcining, roasting, crystalizing, thermal desorption, and pyrolyzing. The unit can be used for remediation of soils, carbon, spent catalyst, RCRA waste and thermal processing of chemicals, carbon black, biomass, coal conversion, minerals, plastics. The equipment ships with the O&M manual certified inspection report, general arrangement, and electrical power distribution drawings. No Motor, requires approximate 10hp motor. We encourage inspection. This Dryer may not be complete with all parts.

Manufacturer Information

Brand: Therma-Flite

Model: ESD 36-30-VAR

Style: A (TWIN)

Description

The Used Therma-Flite Electric-Scru is an electrically heated, indirect continuous processor dryer designed for thermal processing of solids, sludges, and slurries. Featuring a twin screw conveyor design, this unit utilizes electrical resistance heaters integrated into the housing and augers for precise temperature control. The chamber, screw, and shaft are constructed from 316 stainless steel, while the drive and tail end plates are made from 304 stainless steel, ensuring durability and corrosion resistance. Equipped with a control panel, this electrically heated screw-type thermal processor delivers continuous and efficient drying, heating, and processing of various materials.

Specifications

- Model: ESD 36-30-VAR

- Style: A (TWIN)

- Processing Type: Indirect Heating

- Heating Method: Electrical Resistance Heaters

- Material:

- Chamber, Screw, Shaft: 316 Stainless Steel

- Drive & Tail End Plates: 304 Stainless Steel

- Function: Thermal Processing / Drying

- Control System: Integrated Control Panel

- Application: Continuous Processing of Solids, Sludges, and Slurries

Applications

This electrically heated screw-type processor is ideal for industries requiring indirect heating of materials in a continuous process. Typical applications include:

- Industrial Drying & Heating – Processing of various solids, sludges, and slurries

- Waste Treatment – Drying and volume reduction of sludge and waste materials

- Food Processing – Controlled heating of food-based materials

- Chemical Processing – Thermal treatment of chemical powders and mixtures

- Pharmaceutical Processing – Drying and stabilization of pharmaceutical materials

- Biomass & Renewable Energy – Processing of organic waste for biofuel applications

What Products Would This Be Used For?

- Industrial sludge dryers

- Wastewater treatment systems

- Chemical and pharmaceutical drying systems

- Biomass processing units

- Food and ingredient processors

- Heat treatment systems for industrial powders

Used Therma-Flite Electric-Scru, Therma-Flite ESD 36-30-VAR, electrically heated screw processor, twin screw conveyor dryer, indirect thermal processor, industrial sludge dryer, continuous process dryer, stainless steel screw conveyor, electrically heated auger, thermal processing equipment

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory