Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Used Gryphon Biomass Hot Air Belt Dryer Model A.318 – Gas-Fired, Automated Hemp Dryer

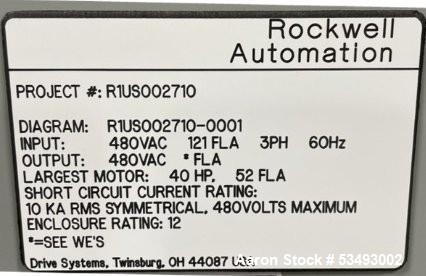

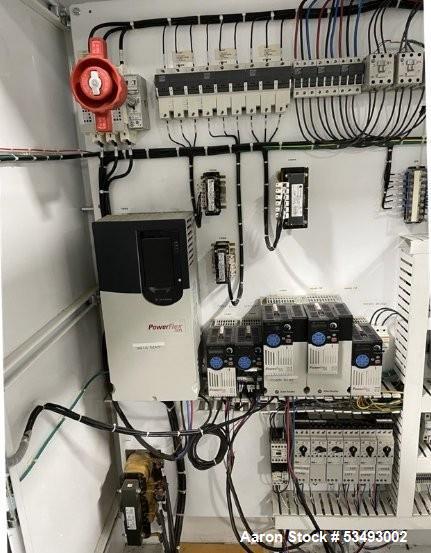

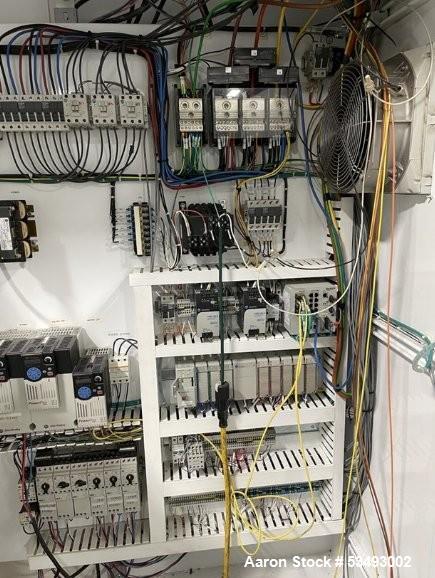

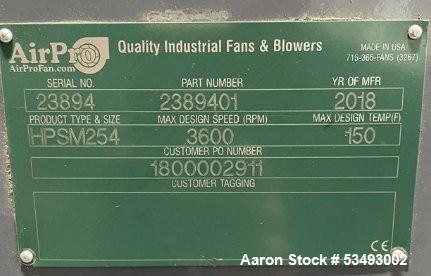

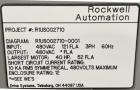

Used Gryphon Biomass Hot Air Belt Dryer. Model A.318 gas fired recirculating counter current air dryer; Approx. 213 lbs/hr water evaporation rate; 18 L x 3 W dryer section; Used for drying hemp w/ inlet moisture of 50-80% and outlet moisture of 7% to 11% moisture running at 3,000 lbs per 24 hours inlet and approximately 1,000 pounds per 24 hours dry mass outlet; 1.5 MMBTU nat. gas burner w/ all gas train valves, firing controls and Honeywell fire eye safeties; Supplemental electric heaters in each section; 2500 scfm blower with AB PowerFlex 753 VFD drive; Model HPSM254 AirPro high pressure radial shrouded fan, 600 RPM, 40HP, Built 2008; (6) PowerFlex 525 VFD drives; Condenser coils; Infeed sifter and lid lift assembly; 23.625" W cleated feed belt; CTS cooling tower and condenser unit; Full automation; Software plc controlled air volume, temperature and cycle time. Automated washing of chambers, air filter, and belt. Spares included: (4) condenser filters, dryer belt, bed skirts & spacers. Built 2019. Previously used for hemp.

| Model | A.318 |

| Category | Dryers - Drying EquipmentDryers - Drying Equipment |

| Subcategory | Belt DryersBelt Dryers |

Manufacturer Information

- Brand: Gryphon

- Model: A.318

- Type: Biomass Hot Air Belt Dryer

- Heat Source: Gas-Fired (1.5 MMBTU natural gas burner) with supplemental electric heaters

- Fan System: HPSM254 AirPro high-pressure radial shrouded fan, 600 RPM, 40 HP

- Automation: Fully PLC controlled with automated washing and adjustable air volume, temperature, and cycle time

- Year Built: 2019

Description

The Gryphon Biomass Hot Air Belt Dryer, Model A.318, is an industrial-grade gas-fired recirculating counter-current air dryer designed for drying biomass materials such as hemp. With a water evaporation rate of approximately 213 lbs/hr, this dryer processes 3,000 lbs of wet biomass per 24 hours and outputs around 1,000 lbs of dry product at a moisture level of 7% to 11%. The dryer section measures 18’ long by 3’ wide and is equipped with a 23.625" cleated feed belt, condenser coils, and a CTS cooling tower and condenser unit.

The unit features a 1.5 MMBTU natural gas burner with all required gas train valves, firing controls, and Honeywell fire eye safeties, along with supplemental electric heaters in each section. Airflow is powered by a 2500 SCFM blower with Allen Bradley PowerFlex 753 VFD and six PowerFlex 525 VFD drives for precise control. Full PLC automation allows for control of air volume, temperature, cycle time, and includes automated washing of the chambers, air filters, and belt.

Specifications

- Water Evaporation Rate: Approx. 213 lbs/hour

- Dryer Section Dimensions: 18’ L x 3’ W

- Input Capacity: 3,000 lbs per 24 hours (50-80% moisture)

- Output Dry Mass: Approx. 1,000 lbs per 24 hours (7% to 11% moisture)

- Burner: 1.5 MMBTU natural gas burner with safety controls

- Supplemental Heaters: Electric heaters in each section

- Airflow: 2500 SCFM blower, AB PowerFlex 753 VFD drive

- Fan: Model HPSM254 AirPro, 600 RPM, 40 HP

- Feed Belt: 23.625” wide cleated belt

- Blowers and VFDs: (6) PowerFlex 525 VFD drives

- Cooling System: CTS cooling tower and condenser unit

- Automation: Full PLC control for air volume, temperature, cycle time, automated washing

- Spare Parts: (4) condenser filters, dryer belt, bed skirts, spacers

- Year Built: 2019

- Previously Used For: Hemp drying

Applications

- Hemp biomass drying

- Agricultural biomass drying (corn, alfalfa, wood chips)

- Food processing (grains, spices, seeds)

- Pharmaceuticals and nutraceutical powders

- Industrial byproduct drying

Compatible Products & Uses

- Hemp biomass

- Agricultural products with high moisture content

- Nutraceutical powders and plant materials

- Wood biomass for pellet production

- Food-grade drying applications

- Gryphon biomass dryer

- Hot air belt dryer

- Used biomass dryer

- Gas-fired belt dryer

- Hemp drying machine

- Biomass drying equipment

- Industrial belt dryer

- Hot air dryer

- PLC controlled dryer

- Recirculating biomass dryer

- Used Gryphon hot air biomass dryer

- Gas-fired recirculating belt dryer

- Industrial biomass drying system

- Hemp biomass drying equipment

- Automated belt dryer with PLC control

- Industrial gas-fired drying machine

- Biomass dryer for agricultural products

- Large capacity biomass drying system

- Used biomass dryer with condenser coils

- Counter-current biomass belt dryer

- Buy used Gryphon biomass hot air belt dryer model A.318

- Gas-fired industrial biomass dryer with full automation

- Recirculating air belt dryer for hemp and agricultural biomass

- Used biomass drying system with PLC and VFD controls

- Best used biomass hot air belt dryer for hemp processing

- Large scale biomass dryer with gas burner and supplemental electric heaters

- Industrial biomass dryer with 213 lbs/hr evaporation rate

- Automated belt drying machine for high moisture biomass

- Counter-current air dryer for large-scale biomass processing

- Pre-owned industrial dryer with condenser unit and cooling tower

- Used Gryphon biomass dryer

- Industrial biomass drying equipment

- Gas-fired hot air belt dryer

- Hemp drying machine for sale

- Biomass belt dryer

- Large capacity biomass dryer

- Industrial biomass drying system

- Gas-fired recirculating air dryer

- Automated hot air dryer

- Buy used biomass dryer

- Buy used biomass dryer

- Sell Gryphon biomass dryer

- Used hemp drying equipment for sale

- Where to buy biomass belt dryers

- Large-scale biomass drying solutions

- Used industrial biomass dryers marketplace

- Affordable used hemp drying machines

- Buy and sell biomass drying equipment

- Used Gryphon hot air belt dryer for sale

- Best deals on biomass drying systems

Used Gryphon Biomass Hot Air Belt Dryer. Model A.318 gas fired recirculating counter current air dryer; Approx. 213 lbs/hr water evaporation rate; 18 L x 3 W dryer section; Used for drying hemp w/ inlet moisture of 50-80% and outlet moisture of 7% to 11% moisture running at 3,000 lbs per 24 hours inlet and approximately 1,000 pounds per 24 hours dry mass outlet; 1.5 MMBTU nat. gas burner w/ all gas train valves, firing controls and Honeywell fire eye safeties; Supplemental electric heaters in each section; 2500 scfm blower with AB PowerFlex 753 VFD drive; Model HPSM254 AirPro high pressure radial shrouded fan, 600 RPM, 40HP, Built 2008; (6) PowerFlex 525 VFD drives; Condenser coils; Infeed sifter and lid lift assembly; 23.625" W cleated feed belt; CTS cooling tower and condenser unit; Full automation; Software plc controlled air volume, temperature and cycle time. Automated washing of chambers, air filter, and belt. Spares included: (4) condenser filters, dryer belt, bed skirts & spacers. Built 2019. Previously used for hemp.

Manufacturer Information

- Brand: Gryphon

- Model: A.318

- Type: Biomass Hot Air Belt Dryer

- Heat Source: Gas-Fired (1.5 MMBTU natural gas burner) with supplemental electric heaters

- Fan System: HPSM254 AirPro high-pressure radial shrouded fan, 600 RPM, 40 HP

- Automation: Fully PLC controlled with automated washing and adjustable air volume, temperature, and cycle time

- Year Built: 2019

Description

The Gryphon Biomass Hot Air Belt Dryer, Model A.318, is an industrial-grade gas-fired recirculating counter-current air dryer designed for drying biomass materials such as hemp. With a water evaporation rate of approximately 213 lbs/hr, this dryer processes 3,000 lbs of wet biomass per 24 hours and outputs around 1,000 lbs of dry product at a moisture level of 7% to 11%. The dryer section measures 18’ long by 3’ wide and is equipped with a 23.625" cleated feed belt, condenser coils, and a CTS cooling tower and condenser unit.

The unit features a 1.5 MMBTU natural gas burner with all required gas train valves, firing controls, and Honeywell fire eye safeties, along with supplemental electric heaters in each section. Airflow is powered by a 2500 SCFM blower with Allen Bradley PowerFlex 753 VFD and six PowerFlex 525 VFD drives for precise control. Full PLC automation allows for control of air volume, temperature, cycle time, and includes automated washing of the chambers, air filters, and belt.

Specifications

- Water Evaporation Rate: Approx. 213 lbs/hour

- Dryer Section Dimensions: 18’ L x 3’ W

- Input Capacity: 3,000 lbs per 24 hours (50-80% moisture)

- Output Dry Mass: Approx. 1,000 lbs per 24 hours (7% to 11% moisture)

- Burner: 1.5 MMBTU natural gas burner with safety controls

- Supplemental Heaters: Electric heaters in each section

- Airflow: 2500 SCFM blower, AB PowerFlex 753 VFD drive

- Fan: Model HPSM254 AirPro, 600 RPM, 40 HP

- Feed Belt: 23.625” wide cleated belt

- Blowers and VFDs: (6) PowerFlex 525 VFD drives

- Cooling System: CTS cooling tower and condenser unit

- Automation: Full PLC control for air volume, temperature, cycle time, automated washing

- Spare Parts: (4) condenser filters, dryer belt, bed skirts, spacers

- Year Built: 2019

- Previously Used For: Hemp drying

Applications

- Hemp biomass drying

- Agricultural biomass drying (corn, alfalfa, wood chips)

- Food processing (grains, spices, seeds)

- Pharmaceuticals and nutraceutical powders

- Industrial byproduct drying

Compatible Products & Uses

- Hemp biomass

- Agricultural products with high moisture content

- Nutraceutical powders and plant materials

- Wood biomass for pellet production

- Food-grade drying applications

| Model | A.318 |

| Category | Dryers - Drying Equipment |

| Subcategory | Belt Dryers |

- Gryphon biomass dryer

- Hot air belt dryer

- Used biomass dryer

- Gas-fired belt dryer

- Hemp drying machine

- Biomass drying equipment

- Industrial belt dryer

- Hot air dryer

- PLC controlled dryer

- Recirculating biomass dryer

- Used Gryphon hot air biomass dryer

- Gas-fired recirculating belt dryer

- Industrial biomass drying system

- Hemp biomass drying equipment

- Automated belt dryer with PLC control

- Industrial gas-fired drying machine

- Biomass dryer for agricultural products

- Large capacity biomass drying system

- Used biomass dryer with condenser coils

- Counter-current biomass belt dryer

- Buy used Gryphon biomass hot air belt dryer model A.318

- Gas-fired industrial biomass dryer with full automation

- Recirculating air belt dryer for hemp and agricultural biomass

- Used biomass drying system with PLC and VFD controls

- Best used biomass hot air belt dryer for hemp processing

- Large scale biomass dryer with gas burner and supplemental electric heaters

- Industrial biomass dryer with 213 lbs/hr evaporation rate

- Automated belt drying machine for high moisture biomass

- Counter-current air dryer for large-scale biomass processing

- Pre-owned industrial dryer with condenser unit and cooling tower

- Used Gryphon biomass dryer

- Industrial biomass drying equipment

- Gas-fired hot air belt dryer

- Hemp drying machine for sale

- Biomass belt dryer

- Large capacity biomass dryer

- Industrial biomass drying system

- Gas-fired recirculating air dryer

- Automated hot air dryer

- Buy used biomass dryer

- Buy used biomass dryer

- Sell Gryphon biomass dryer

- Used hemp drying equipment for sale

- Where to buy biomass belt dryers

- Large-scale biomass drying solutions

- Used industrial biomass dryers marketplace

- Affordable used hemp drying machines

- Buy and sell biomass drying equipment

- Used Gryphon hot air belt dryer for sale

- Best deals on biomass drying systems

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory