Hands-Off Approach

Rebuilding Process Equipment

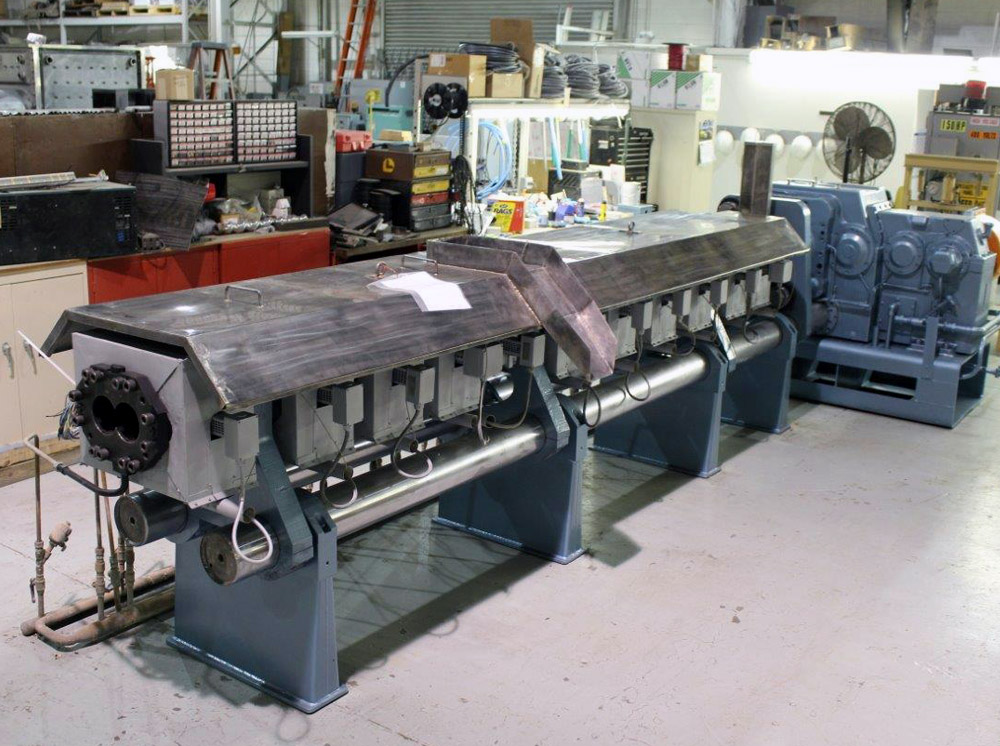

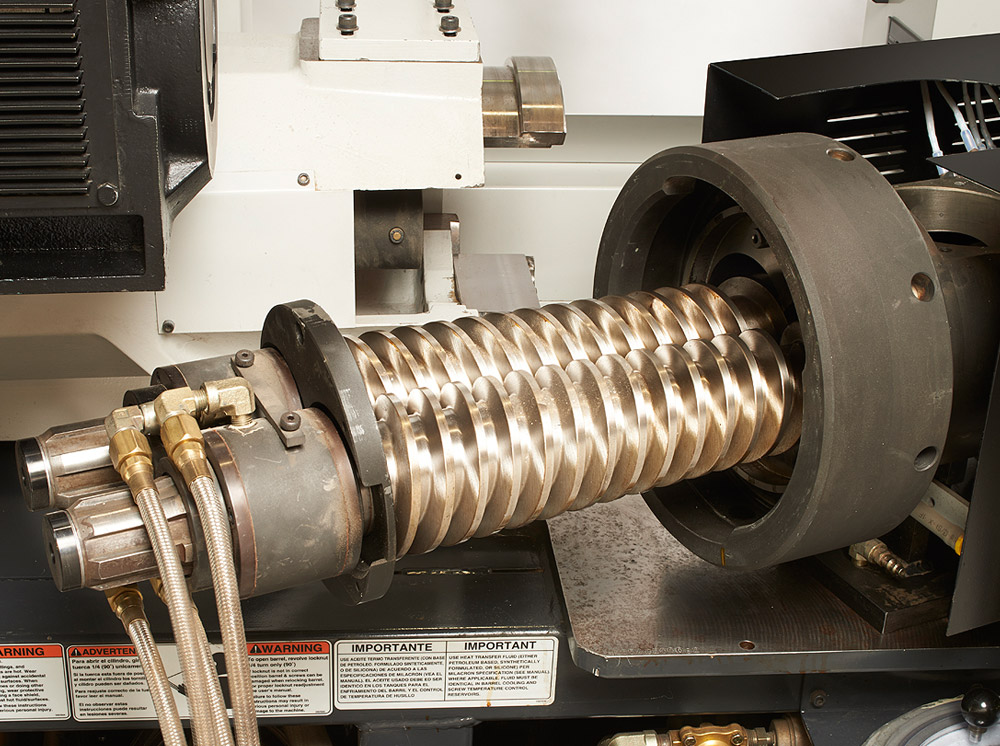

For those customers who prefer a hands-off approach to buying used equipment, our complete reconditioning services supply a happy medium. They eliminate all project management aspects from the equation for you.

From our 40,000 sq. ft. shop, we rebuild most types of processing equipment from the ground up to next-to-new condition. In addition, we can cater solutions to all your process equipment requirements.

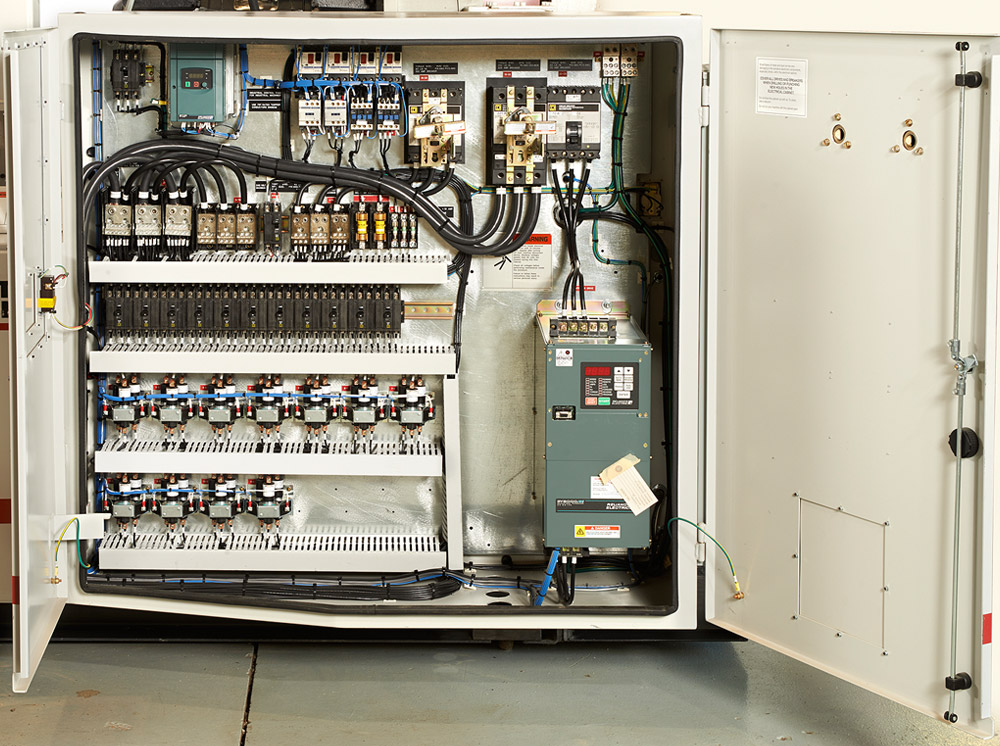

Whether it’s a new drive system or a PLC controls system you’re seeking, you can count on Aaron Equipment Company’s expert team to assist you in acquiring the equipment that’s right for you.