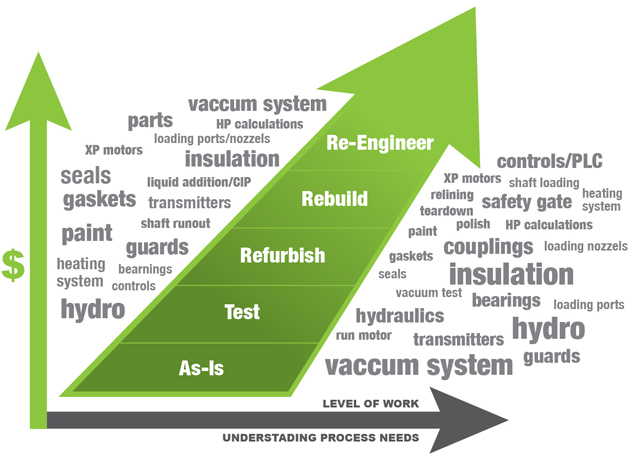

Aaron Equipment Company Shop's Competitive Advantage

The Aaron Equipment Company Shop is located onsite at our headquarters near Chicago’s O’Hare International Airport in Illinois. Encompassing 100,000 square feet, the Aaron Shop is capable of Testing and Complete Reconditioning of most items in our inventory. The Shop is equipped with multiple cranes that are capable of handling up to 30 tons of machinery. Of that expansive space, it is also climate controlled, ensuring an ideal temperature and humidity environment while the equipment is being serviced.